Article contents

Microstructure and mechanical property of Cu/In–45Cu/Ni solder joints formed by transient liquid phase bonding

Published online by Cambridge University Press: 13 August 2020

Abstract

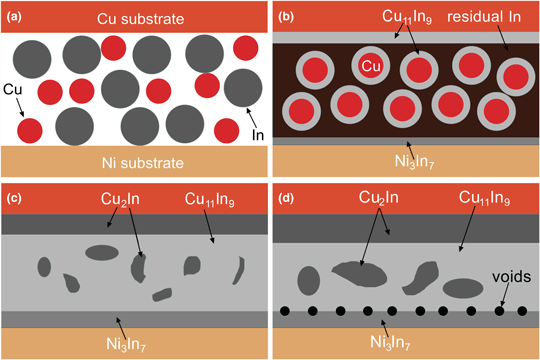

In this paper, the microstructure and the shear property of Cu/In–45Cu/Ni solder joints by transient liquid phase were studied, and the intermetallic compounds (IMCs) growth mechanism was investigated. The results showed that the IMCs volume ratio of solder joints was increased firstly and then decreased with increasing bonding time, and the IMCs volume ratio reached its maximum value of 95.8% at 60 min. The Cu interfacial IMC of the solder joint with dense microstructure was Cu2In phase at 60 min, and the Ni interfacial IMC was Ni3In7. The maximum shear strength of solder joints was obtained at 60 min, which is 15.21 MPa. The shear fracture appeared honeycomb structure, and the fracture occurred at the phase interface of Ni3In7/Cu11In9. The thickness of the interfacial IMCs and the white IMCs around the Cu particles (Cu@IMC) was increased continuously with increasing bonding time, and thus, the interconnection of Cu–Ni substrates was realized ultimately.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 2

- Cited by