Article contents

High-rate dislocation motion in stable nanocrystalline metals

Published online by Cambridge University Press: 19 March 2019

Abstract

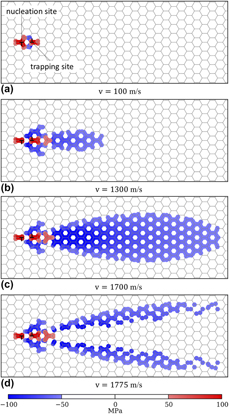

Dislocation-mediated plasticity in stable nanocrystalline metals, where grain boundary motion is suppressed, is revisited in the context of dislocation elastodynamics. The effect of transient waves that emanate from the generation and motion of dislocations is quantified for an idealized Cu–10 at.% Ta system with grain sizes on the order of 50 nanometers. Simulations indicate that for this material, as dislocation velocities approach 0.6–0.8 times the shear wave speed, grains several grain diameters away from the initial glide event experience a large transient shear stress for a finite duration. These transient shear stresses increase with increasing glide velocity and can activate nucleation sites far from the original nucleation event. These considerations are used to explain recent experimental observations of a lack of increase in flow stress with increasing loading rate, as well as localization resistance, in this class of stable nanocrystalline metals.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 13: Focus Issue: Intrinsic and Extrinsic Size Effects in Materials , 15 July 2019 , pp. 2252 - 2262

- Copyright

- Copyright © Materials Research Society 2019

References

- 2

- Cited by