Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

YIN, Yan-fei

XU, Wei

SUN, Qiao-yan

XIAO, Lin

and

SUN, Jun

2015.

Deformation and fracture behavior of commercially pure titanium with gradient nano-to-micron-grained surface layer.

Transactions of Nonferrous Metals Society of China,

Vol. 25,

Issue. 3,

p.

738.

Wang, Qi

Sun, Qiaoyan

Xiao, Lin

and

Sun, Jun

2016.

Effect of Surface Nanocrystallization on Fatigue Behavior of Pure Titanium.

Journal of Materials Engineering and Performance,

Vol. 25,

Issue. 1,

p.

241.

Wang, Qi

Sun, Qiaoyan

Xiao, Lin

and

Sun, Jun

2016.

Torsion fatigue behavior of pure titanium with a gradient nanostructured surface layer.

Materials Science and Engineering: A,

Vol. 649,

Issue. ,

p.

359.

Liu, Y.G.

Li, M.Q.

and

Liu, H.J.

2016.

Surface nanocrystallization and gradient structure developed in the bulk TC4 alloy processed by shot peening.

Journal of Alloys and Compounds,

Vol. 685,

Issue. ,

p.

186.

Kolobov, Yu. R.

Manokhin, S. S.

Kolobova, A. Yu.

Kudymova, Yu. E.

Betekhtin, V. I.

Golyshev, A. A.

Molodets, A. M.

and

Andrievskii, R. A.

2016.

Shock-wave-induced grain refinement and phase state modification in coarse-grained and nanocrystalline titanium.

Technical Physics Letters,

Vol. 42,

Issue. 9,

p.

959.

Andrievski, Rostislav A.

and

Khatchoyan, Arsen V.

2016.

Nanomaterials in Extreme Environments.

Vol. 230,

Issue. ,

p.

7.

Wang, Lifei

Zhang, Hua

Huang, Guangsheng

Cao, Miao

Cao, Xiaoqing

Mostaed, Ehsan

and

Vedani, Maurizio

2016.

Formability and anisotropy of the mechanical properties in commercially pure titanium after various routes normal and different speed rolling.

Journal of Materials Research,

Vol. 31,

Issue. 21,

p.

3372.

Andrievski, Rostislav A.

and

Khatchoyan, Arsen V.

2016.

Nanomaterials in Extreme Environments.

Vol. 230,

Issue. ,

p.

55.

Betekhtin, V. I.

Kadomtsev, A. G.

and

Narykova, M. V.

2017.

Effect of the allotropic transition in titanium on its interatomic interaction energy.

Technical Physics Letters,

Vol. 43,

Issue. 8,

p.

708.

Wang, Q.

Xin, C.

Sun, Q.

Xiao, L.

and

Sun, J.

2017.

Biaxial tension-torsion fatigue behavior of gradient nano-grained pure titanium fabricated by surface nanocrystallization.

Materials Science and Engineering: A,

Vol. 702,

Issue. ,

p.

125.

Wang, Peng

Yang, Xinhua

and

Peng, Di

2017.

Molecular dynamics investigation of the grain boundary migration hysteresis of nanocrystalline Ni under cyclic shear loading.

Modelling and Simulation in Materials Science and Engineering,

Vol. 25,

Issue. 2,

p.

025006.

Chae, Jong-Min

Lee, Keun-Oh

and

Amanov, Auezhan

2018.

Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy.

Materials,

Vol. 11,

Issue. 3,

p.

452.

Ding, Jie

Li, Q.

Li, Jin

Xue, S.

Fan, Z.

Wang, H.

and

Zhang, X.

2018.

Mechanical behavior of structurally gradient nickel alloy.

Acta Materialia,

Vol. 149,

Issue. ,

p.

57.

Xin, Chao

Sun, Qiaoyan

Xiao, Lin

and

Sun, Jun

2018.

Biaxial fatigue property enhancement of gradient ultra-fine-grained Zircaloy-4 prepared by surface mechanical rolling treatment.

Journal of Materials Science,

Vol. 53,

Issue. 17,

p.

12492.

Wang, Q.

Xin, C.

Sun, Q.

Xiao, L.

and

Sun, J.

2018.

Biaxial fatigue behavior of gradient structural purity titanium under in-phase and out-of-phase loading.

International Journal of Fatigue,

Vol. 116,

Issue. ,

p.

602.

Fronczek, D.M.

Saksl, K.

Chulist, R.

Michalik, S.

Wojewoda-Budka, J.

Sniezek, L.

Wachowski, M.

Torzewski, J.

Sulikova, M.

Sulova, K.

Lachova, A.

Fejercak, M.

Daisenberger, D.

Szulc, Z.

and

Kania, Z.

2018.

Residual stresses distribution, correlated with bending tests, within explosively welded Ti gr. 2/A1050 bimetals.

Materials Characterization,

Vol. 144,

Issue. ,

p.

461.

Lee, Hak Hyeon

Yoon, Jae Ik

Park, Hyung Keun

and

Kim, Hyoung Seop

2019.

Unique microstructure and simultaneous enhancements of strength and ductility in gradient-microstructured Cu sheet produced by single-roll angular-rolling.

Acta Materialia,

Vol. 166,

Issue. ,

p.

638.

Zhu, Lihua

Guan, Yanjin

Lin, Jun

Zhai, Jiqiang

and

Xie, Zhendong

2019.

The enhanced thermal stability of the nanocrystalline-amorphous composite layer on pure titanium induced by ultrasonic shot peening.

Journal of Alloys and Compounds,

Vol. 791,

Issue. ,

p.

1063.

Wang, Qi

Ren, Junqiang

Wang, Yinling

Xin, Chao

Xiao, Lin

and

Yang, Dan

2019.

Deformation and fracture mechanisms of gradient nanograined pure Ti produced by a surface rolling treatment.

Materials Science and Engineering: A,

Vol. 754,

Issue. ,

p.

121.

Huang, Z.W.

Yong, P.L.

Liang, N.N.

and

Li, Y.S.

2019.

Slip, twinning and twin-twin interaction in a gradient structured titanium.

Materials Characterization,

Vol. 149,

Issue. ,

p.

52.

$\overline 1$2} deformation twins together with a low fraction of {11

$\overline 1$2} deformation twins together with a low fraction of {11 $\overline 2$2} and {11

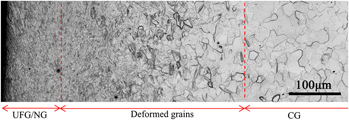

$\overline 2$2} and {11 $\overline 2$4} twins were identified. Based on the microstructural analysis, the grain refinement mechanisms with increasing strain are summarized as: (i) prior division by deformation twinning, (ii) refinement effect of subgrain boundaries resulting from the accumulation of high density of dislocation, and (iii) transformation effect from low angle grain boundaries to high angle grain boundaries. The results of tension tests also show that the titanium sample after SRT shows higher strength than the as-received titanium sample.

$\overline 2$4} twins were identified. Based on the microstructural analysis, the grain refinement mechanisms with increasing strain are summarized as: (i) prior division by deformation twinning, (ii) refinement effect of subgrain boundaries resulting from the accumulation of high density of dislocation, and (iii) transformation effect from low angle grain boundaries to high angle grain boundaries. The results of tension tests also show that the titanium sample after SRT shows higher strength than the as-received titanium sample.