Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Nam, Seungjin

Shin, Se Eun

Kim, Jae-Hun

and

Choi, Hyunjoo

2020.

Effect of Powder Morphology and Chemical Distribution on Properties of Multicomponent Alloys Produced Via Powder Metallurgy.

Metals and Materials International,

Vol. 26,

Issue. 9,

p.

1385.

Picak, S.

Wegener, T.

Sajadifar, S.V.

Sobrero, C.

Richter, J.

Kim, H.

Niendorf, T.

and

Karaman, I.

2021.

On the low-cycle fatigue response of CoCrNiFeMn high entropy alloy with ultra-fine grain structure.

Acta Materialia,

Vol. 205,

Issue. ,

p.

116540.

Nam, Seungjin

Kim, Sang Jun

Yoon, Kook Noh

Kim, Moon J.

Quevedo-Lopez, Manuel

Hwang, Jun Yeon

Park, Eun Soo

and

Choi, Hyunjoo

2022.

Design of metastable complex-concentrated alloys through composition tailoring.

Materials & Design,

Vol. 224,

Issue. ,

p.

111391.

Fu, Tao

Hu, Hao

Hu, Sen

Liang, Qihao

Weng, Shayuan

Zhao, Yinbo

Chen, Xiang

and

Peng, Xianghe

2022.

Twin boundary migration and reactions with stacking fault tetrahedron in Cu and CoCrCuFeNi high-entropy alloy.

Journal of Materials Research and Technology,

Vol. 17,

Issue. ,

p.

282.

Zhang, Dingchang

Kenel, Christoph

and

Dunand, David C.

2022.

Microstructure and mechanical properties of 3D ink-extruded CoCrCuFeNi microlattices.

Acta Materialia,

Vol. 238,

Issue. ,

p.

118187.

Wang, Mingze

Wen, Zhiqin

Liu, Junxiao

Wang, Jingyang

Wu, Zhenyu

Qin, Jiedong

and

Zhao, Yuhong

2023.

Synergistic effect of Zr and Hf alloying on cross fluvial microstructure of CoCrFeNi eutectic high-entropy alloys.

Materials Letters,

Vol. 345,

Issue. ,

p.

134416.

Zhu, Bo

Zhao, Dan

Niu, Yihan

Zhang, Zhenqiao

and

Zhao, Hongwei

2023.

Atomic study on the deformation behavior of nanotwinned CoCrCuFeNi high entropy alloy during nanoscratching.

Journal of Materials Research and Technology,

Vol. 25,

Issue. ,

p.

4020.

Li, N.

Zhang, H.

Wu, L.H.

Li, Z.K.

Fu, H.M.

Ni, D.R.

Xue, P.

Liu, F.C.

Xiao, B.L.

and

Ma, Z.Y.

2023.

Simultaneously increasing mechanical and corrosion properties in CoCrFeNiCu high entropy alloy via friction stir processing with an improved hemispherical convex tool.

Materials Characterization,

Vol. 203,

Issue. ,

p.

113143.

Liu, Le

Xia, Hongyong

Tang, Yan

Cao, Qigao

Li, Lanyun

Dong, Longlong

and

Zhang, Yusheng

2023.

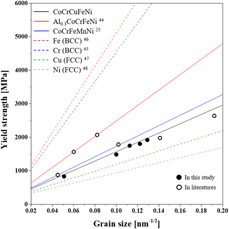

Microstructure and Mechanical Properties of CoCrCuFeNi High-Entropy Alloys Synthesized by Powder Metallurgy and Spark Plasma Sintering.

Journal of Materials Engineering and Performance,

Nguyen, Hoang-Giang

Fang, Te-Hua

and

Doan, Dinh-Quan

2023.

Cyclic plasticity and deformation mechanism of AlCrCuFeNi high entropy alloy.

Journal of Alloys and Compounds,

Vol. 940,

Issue. ,

p.

168838.

Loginov, Pavel A.

Fedotov, Alexander D.

Mukanov, Samat K.

Manakova, Olga S.

Zaitsev, Alexander A.

Akhmetov, Amankeldy S.

Rupasov, Sergey I.

and

Levashov, Evgeny A.

2023.

Manufacturing of Metal–Diamond Composites with High-Strength CoCrCuxFeNi High-Entropy Alloy Used as a Binder.

Materials,

Vol. 16,

Issue. 3,

p.

1285.

Amalia, Lia

Li, Yongkang

Bei, Hongbin

Chen, Yan

Yu, Dunji

An, Ke

Lyu, Zongyang

Liaw, Peter K.

Zhang, Yanwen

Ding, Qingqing

and

Gao, Yanfei

2024.

Copper effects on the microstructures and deformation mechanisms of CoCrFeNi high entropy alloys.

Applied Physics Letters,

Vol. 124,

Issue. 14,

Han, Juyeon

Nam, Seungjin

Choi, Yeon Taek

Jang, Tae Jin

Jung, Chahee

Sohn, Seok Su

Kim, Hyoung Seop

and

Choi, Hyunjoo

2024.

Grain boundary strengthening in nanocrystalline Mo0.2CoNi medium-entropy alloys produced via high-pressure torsion.

International Journal of Refractory Metals and Hard Materials,

Vol. 119,

Issue. ,

p.

106535.

Nam, Seungjin

Son, Hansol

Song, Yongwook

Han, Juyeon

Ko, Won-Seok

Sohn, Seok Su

Kim, Hyoung Seop

and

Choi, Hyunjoo

2024.

Activation of deformation twinning in ultrafine-grained high-entropy alloys via tailoring stacking fault energy and critical twinning stress.

Materials Science and Engineering: A,

Vol. 897,

Issue. ,

p.

146055.

Adaan‐Nyiak, Moses A.

Alam, Intekhab

Jossou, Ericmoore

Hwang, Sooyeon

Kisslinger, Kim

Gill, Simerjeet K.

and

Tiamiyu, Ahmed A.

2024.

Design and Development of Stable Nanocrystalline High‐Entropy Alloy: Coupling Self‐Stabilization and Solute Grain Boundary Segregation Effects.

Small,