1. Introduction

Flow of viscous liquid in a deformable gap bounded by an elastic plate or membrane is ubiquitous in nature and in the laboratory. Examples include laccolith formation where magma spreads under a deformable layer of rock (Pollard & Johnson Reference Pollard and Johnson1973), flow in the cardiovascular or respiratory system in the body (Grotberg & Jensen Reference Grotberg and Jensen2004) and flow in elastic microfluidic devices (Christov et al. Reference Christov, Cognet, Shidhore and Stone2018).

In this paper, we study the case where the liquid is spreading in the narrow gap between a flat rigid base and an overlying elastic sheet (Hosoi & Mahadevan Reference Hosoi and Mahadevan2004), which is the elastic-lidded analogue of a spreading viscous gravity current or capillary droplet. For these spreading problems, it is natural to model the bulk of the liquid using the Navier–Stokes equations with a no-slip boundary condition on the rigid base (and free slip or no slip on the upper surface, depending on whether it is a free surface or covered by the elastic lid). However, at the front of the spreading liquid, the moving contact line poses a problem since the viscous dissipation diverges as the liquid height tends to zero (Huh & Scriven Reference Huh and Scriven1971), and hence other physical effects must come into play near the contact line to cut off the divergence.

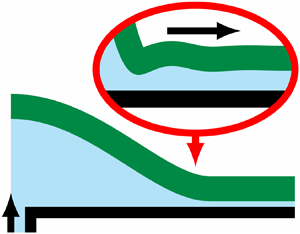

The spreading under an elastic sheet has been studied with various physical mechanisms at the moving front, including a pre-wetting film (e.g. Lister, Peng & Neufeld Reference Lister, Peng and Neufeld2013; Hewitt, Balmforth & De Bruyn Reference Hewitt, Balmforth and De Bruyn2015), a fluid lag (e.g. Hewitt et al. Reference Hewitt, Balmforth and De Bruyn2015; Ball & Neufeld Reference Ball and Neufeld2018; Wang & Detournay Reference Wang and Detournay2018) and elastic fracture (e.g. Bunger & Cruden Reference Bunger and Cruden2011; Wang & Detournay Reference Wang and Detournay2018; Lister, Skinner & Large Reference Lister, Skinner and Large2019), and sometimes with additional complications such as surface tension between two phases (e.g. Peng et al. Reference Peng, Pihler-Puzović, Juel, Heil and Lister2015) or adhesive forces between the boundaries (e.g. Ball & Neufeld Reference Ball and Neufeld2018). We focus on spreading over a pre-wetting layer of thickness ![]() $h_0$, as shown in figure 1. This set-up can also be interpreted as injection in an elastic-walled Hele-Shaw cell, which has been studied by e.g. Pihler-Puzović et al. (Reference Pihler-Puzović, Illien, Heil and Juel2012) and Pihler-Puzović et al. (Reference Pihler-Puzović, Peng, Lister, Heil and Juel2018) in the context of controlling the Saffman–Taylor viscous-fingering instability.

$h_0$, as shown in figure 1. This set-up can also be interpreted as injection in an elastic-walled Hele-Shaw cell, which has been studied by e.g. Pihler-Puzović et al. (Reference Pihler-Puzović, Illien, Heil and Juel2012) and Pihler-Puzović et al. (Reference Pihler-Puzović, Peng, Lister, Heil and Juel2018) in the context of controlling the Saffman–Taylor viscous-fingering instability.

Figure 1. Schematic figure of fluid injected under an elastic sheet with either two-dimensional or axisymmetric geometry.

Some aspects of this system have been studied theoretically (Flitton & King Reference Flitton and King2004; Lister et al. Reference Lister, Peng and Neufeld2013; Hewitt et al. Reference Hewitt, Balmforth and De Bruyn2015) using the method of matched asymptotic expansions, exploiting the separation of length scales between the large central ‘blister’ of fluid, where viscous forces can be neglected, and the small ‘peeling region’ near the apparent contact line, where viscous forces are important. In the blister, the viscous pressure drop is asymptotically negligible, so the blister has a quasi-static shape analogous to the spherical-cap shape of a capillary droplet. The peeling region has a travelling-wave solution, moving outwards at some speed ![]() $\dot R = \mathrm {d}R/\mathrm {d}t$. If either bending stresses or tension forces alone are dominant, then the peeling speed depends on the apparent curvature

$\dot R = \mathrm {d}R/\mathrm {d}t$. If either bending stresses or tension forces alone are dominant, then the peeling speed depends on the apparent curvature ![]() $\kappa = \mathrm {d}^2h/\mathrm {d}x^2$ or slope

$\kappa = \mathrm {d}^2h/\mathrm {d}x^2$ or slope ![]() $\alpha = -\mathrm {d}h/\mathrm {d}x$ at the edge of the blister solution according to the ‘peeling-by-bending’ or ‘peeling-by-pulling’ laws (see e.g. Lister et al. Reference Lister, Peng and Neufeld2013)

$\alpha = -\mathrm {d}h/\mathrm {d}x$ at the edge of the blister solution according to the ‘peeling-by-bending’ or ‘peeling-by-pulling’ laws (see e.g. Lister et al. Reference Lister, Peng and Neufeld2013)

\begin{equation} \dot R = 0.472\frac{B h_0^{1/2} \kappa^{5/2}}{12\mu} \quad \text{or} \quad \dot R = \frac{T \alpha^3}{12\mu \ln[(R/\ell_{p})^3]}, \end{equation}

\begin{equation} \dot R = 0.472\frac{B h_0^{1/2} \kappa^{5/2}}{12\mu} \quad \text{or} \quad \dot R = \frac{T \alpha^3}{12\mu \ln[(R/\ell_{p})^3]}, \end{equation}

respectively, where ![]() $\mu$ is the dynamic viscosity of the fluid,

$\mu$ is the dynamic viscosity of the fluid, ![]() $B$ is the bending stiffness of the sheet,

$B$ is the bending stiffness of the sheet, ![]() $T$ is the tension in the sheet and

$T$ is the tension in the sheet and ![]() $\ell _{p}$ is the length scale of the peeling region. (The peeling-by-pulling law (1.1b) is the elastic analogue of the Cox–Voinov law (Voinov Reference Voinov1976; Cox Reference Cox1986) for capillary spreading.) Integration of the resulting differential equation then yields the spreading law

$\ell _{p}$ is the length scale of the peeling region. (The peeling-by-pulling law (1.1b) is the elastic analogue of the Cox–Voinov law (Voinov Reference Voinov1976; Cox Reference Cox1986) for capillary spreading.) Integration of the resulting differential equation then yields the spreading law ![]() $R(t)$ for the blister at late times when any initial transient behaviour has become irrelevant.

$R(t)$ for the blister at late times when any initial transient behaviour has become irrelevant.

The aim of this paper is to unify and extend the work by Lister et al. (Reference Lister, Peng and Neufeld2013) and Hewitt et al. (Reference Hewitt, Balmforth and De Bruyn2015). These studies considered various, but not all, combinations of bending, tension and gravitational forces and were restricted to the case of constant injection flux. We will, for both two-dimensional and axisymmetric geometries, systematically identify all the possible asymptotic combinations, revealing a rich variety of different behaviours. We calculate the asymptotic spreading laws ![]() $R(t)$ for each case, while allowing fluid to be injected at an arbitrary power-law rate (which also includes the important case of constant-volume spreading).

$R(t)$ for each case, while allowing fluid to be injected at an arbitrary power-law rate (which also includes the important case of constant-volume spreading).

A possible complicating factor is that the deflection of the elastic sheet also causes it to stretch and hence generates tension in the sheet, which is additional to the original constant tension imposed externally by the far-field boundary conditions. This additional tension is studied using the Föppl–von-Kármán equations in Peng & Lister (Reference Peng and Lister2020), so is assumed to be negligible here for simplicity. The condition for its neglect is discussed briefly in § 8.2.

This paper is laid out as follows. We present the governing equations in § 2. The pressure driving the flow is coupled to the liquid height by bending, tension and gravitational forces. We identify three key transition length scales that determine which combination of forces is dominant and determine the full regime diagram in § 3. We then investigate the key travelling-wave peeling solutions (§ 4), and combine them with quasi-static blister solutions to obtain asymptotic predictions for each possible combination of dominant driving forces (§ 5). The asymptotic results are verified against numerical results in § 6, and some further regimes are identified in § 7. The main points are summarized in § 8, and several generalizations of the asymptotic analysis, including to different physical controls of the peeling front, are discussed. The extraordinary variety of asymptotic results is shown in table 1, and the different regimes are shown schematically in figures 2 and 5.

Figure 2. Schematic regime diagrams showing the succession of dominant terms in (2.3) (on logarithmic axes) for the cases (a) ![]() ${L_{TG}} \ll {L_{BT}}$ and (b)

${L_{TG}} \ll {L_{BT}}$ and (b) ![]() ${L_{BT}} \ll {L_{TG}}$, with

${L_{BT}} \ll {L_{TG}}$, with ![]() ${L_{BG}} = ({L_{BT}} {L_{TG}})^{1/2}$. Main panels show which regime (combination of dominant terms) the system is in for different values of the largest scale

${L_{BG}} = ({L_{BT}} {L_{TG}})^{1/2}$. Main panels show which regime (combination of dominant terms) the system is in for different values of the largest scale ![]() $R$ and the smallest scale

$R$ and the smallest scale ![]() $\ell _{p}$ of the system. The arrows show possible transitions between regimes as

$\ell _{p}$ of the system. The arrows show possible transitions between regimes as ![]() $R(t)$ increases (moving to the right) for the case that

$R(t)$ increases (moving to the right) for the case that ![]() $\ell _{p}(t)$ increases (moving upwards). The main discussion in this paper covers the unshaded areas, while the shaded areas are discussed in § 7.1. Arrows above main panels show the transition lengths (3.2) and which term dominates on a length scale

$\ell _{p}(t)$ increases (moving upwards). The main discussion in this paper covers the unshaded areas, while the shaded areas are discussed in § 7.1. Arrows above main panels show the transition lengths (3.2) and which term dominates on a length scale ![]() $L$.

$L$.

Table 1. Summary of results in this paper for various asymptotic limits, showing the exponent ![]() $\delta$ in

$\delta$ in ![]() $R(t) \propto t^\delta$ for various cases in two-dimensional and axisymmetric geometries with power-law injection rates (i.e.

$R(t) \propto t^\delta$ for various cases in two-dimensional and axisymmetric geometries with power-law injection rates (i.e. ![]() $V(t) \propto t^\beta$). See the discussion in § 8. The mechanism driving the spreading is either bending (

$V(t) \propto t^\beta$). See the discussion in § 8. The mechanism driving the spreading is either bending (![]() $B$), tension (

$B$), tension (![]() $T$), gravity (

$T$), gravity (![]() $G$) or a combination as seen in figure 2. For viscously controlled peeling by pulling, there is also a logarithmic factor (indicated by an asterisk). In each column, cases with the same exponent and numerical prefactor are grouped together.

$G$) or a combination as seen in figure 2. For viscously controlled peeling by pulling, there is also a logarithmic factor (indicated by an asterisk). In each column, cases with the same exponent and numerical prefactor are grouped together.

2. Governing equations

We consider the situation shown in figure 1. Viscous liquid fills the narrow gap, of initial height ![]() $h_0$, between a horizontal rigid lower boundary and a thin overlying elastic sheet. The liquid has dynamic viscosity

$h_0$, between a horizontal rigid lower boundary and a thin overlying elastic sheet. The liquid has dynamic viscosity ![]() $\mu$ and density

$\mu$ and density ![]() $\rho$, and is acted on by gravity (acceleration

$\rho$, and is acted on by gravity (acceleration ![]() $g$). The sheet has bending stiffness

$g$). The sheet has bending stiffness ![]() $B = Ed^3/12(1-\nu ^2)$, where

$B = Ed^3/12(1-\nu ^2)$, where ![]() $E$ is the Young's modulus,

$E$ is the Young's modulus, ![]() $\nu$ is the Poisson's ratio and

$\nu$ is the Poisson's ratio and ![]() $d$ is the thickness of the sheet, and is also under an imposed tension

$d$ is the thickness of the sheet, and is also under an imposed tension ![]() $T$. We assume that these quantities are all constant.

$T$. We assume that these quantities are all constant.

The vertical length scales of the system are assumed to be small compared with the horizontal length scales, so that vertically integrated or averaged quantities can be employed, which are functions of the horizontal position vector ![]() $\boldsymbol {x} = (x,y)$ and time

$\boldsymbol {x} = (x,y)$ and time ![]() $t$. (All vectors and tensors here have only horizontal components.) We consider both two-dimensional (2-D) and axisymmetric (axi) geometries. For the two-dimensional geometry, we assume that fluid is injected along a line source

$t$. (All vectors and tensors here have only horizontal components.) We consider both two-dimensional (2-D) and axisymmetric (axi) geometries. For the two-dimensional geometry, we assume that fluid is injected along a line source ![]() $x=0$ and spreads symmetrically in the

$x=0$ and spreads symmetrically in the ![]() $x$-direction. For the axisymmetric geometry, we define the radial coordinate

$x$-direction. For the axisymmetric geometry, we define the radial coordinate ![]() $r = |\boldsymbol {x}|$ and assume that fluid is injected at the origin

$r = |\boldsymbol {x}|$ and assume that fluid is injected at the origin ![]() $r=0$ and spreads axisymmetrically in the

$r=0$ and spreads axisymmetrically in the ![]() $r$-direction. We use

$r$-direction. We use ![]() $\boldsymbol {\nabla }$ to denote the horizontal gradient operator, primes to denote differentiation with respect to the main horizontal coordinate

$\boldsymbol {\nabla }$ to denote the horizontal gradient operator, primes to denote differentiation with respect to the main horizontal coordinate ![]() $x$ or

$x$ or ![]() $r$, and overdots to denote differentiation with respect to time.

$r$, and overdots to denote differentiation with respect to time.

We seek to predict the evolution of the cell height profile ![]() $h(\boldsymbol {x},t)$ (i.e. the thickness of the fluid layer), which for simplicity we often write as

$h(\boldsymbol {x},t)$ (i.e. the thickness of the fluid layer), which for simplicity we often write as ![]() $h(x)$ or

$h(x)$ or ![]() $h(r)$, leaving the dependence on

$h(r)$, leaving the dependence on ![]() $t$ understood. We focus in particular on the height and radius of the blister of injected fluid, defined by

$t$ understood. We focus in particular on the height and radius of the blister of injected fluid, defined by

(In (2.1b) we have chosen to define the blister radius as the distance from the origin to the closest point at which ![]() $h=h_0$. The deflection

$h=h_0$. The deflection ![]() $h-h_0$ typically has decaying oscillations in

$h-h_0$ typically has decaying oscillations in ![]() $|{\boldsymbol {x}}|>R$ and there are other reasonable choices, for example the distance to the closest minimum of

$|{\boldsymbol {x}}|>R$ and there are other reasonable choices, for example the distance to the closest minimum of ![]() $h$, but the difference is negligible at late times.)

$h$, but the difference is negligible at late times.)

The net upward pressure ![]() $p_e$ on the sheet and the deflection

$p_e$ on the sheet and the deflection ![]() $h - h_0$ of the sheet are coupled by the Föppl–von-Kármán equations (e.g. Landau & Lifshitz Reference Landau and Lifshitz1986), which for constant imposed tension

$h - h_0$ of the sheet are coupled by the Föppl–von-Kármán equations (e.g. Landau & Lifshitz Reference Landau and Lifshitz1986), which for constant imposed tension ![]() $T$ simplify to

$T$ simplify to

The two terms describe, respectively, the effects of induced bending stresses (cf. the Euler beam equation) and imposed tension (cf. the Young–Laplace equation) in the sheet.

We model the viscous flow using lubrication theory (Reynolds Reference Reynolds1886). The lubrication flow is driven by horizontal gradients in the pressure field, so we can leave out pressure contributions that have no horizontal gradient, such as the atmospheric pressure, the weight of the sheet, and the vertical hydrostatic variation. The resulting effective pressure ![]() $p(\boldsymbol {x},t)$, hereafter referred to as just ‘the pressure’, is due both to the elastic forces in the sheet and to the net hydrostatic pressure

$p(\boldsymbol {x},t)$, hereafter referred to as just ‘the pressure’, is due both to the elastic forces in the sheet and to the net hydrostatic pressure

We neglect any horizontal motion of the overlying sheet, and obtain a parabolic Poiseuille-flow profile. This yields the depth-integrated flux ![]() $\boldsymbol {q}(\boldsymbol {x},t)$, from which the evolution of the height profile is found by mass conservation,

$\boldsymbol {q}(\boldsymbol {x},t)$, from which the evolution of the height profile is found by mass conservation,

Equations (2.3) and (2.4) are supplemented by far-field conditions for decay to the undisturbed pre-wetting film and symmetry conditions at the origin

The volume ![]() $V(t)$ of injected fluid is assumed to follow a power law,

$V(t)$ of injected fluid is assumed to follow a power law,

with an injection exponent ![]() $\beta \geq 0$. (In the two-dimensional case,

$\beta \geq 0$. (In the two-dimensional case, ![]() $V(t)$ denotes the volume per unit width in the third dimension in the region

$V(t)$ denotes the volume per unit width in the third dimension in the region ![]() $x \geq 0$, which is half the total amount by symmetry.) The injection flux at the origin is thus given by

$x \geq 0$, which is half the total amount by symmetry.) The injection flux at the origin is thus given by

We use the initial condition ![]() $h = h_0$ at

$h = h_0$ at ![]() $t=0$, except that for

$t=0$, except that for ![]() $\beta = 0$ (constant volume) the injected volume is initially localized to a very small region near the origin.

$\beta = 0$ (constant volume) the injected volume is initially localized to a very small region near the origin.

3. Scaling analysis and transition lengths

We first need to determine which of bending, tension and gravity are dominant, and which can be neglected. In a region with height scale ![]() $H$ and length scale

$H$ and length scale ![]() $L$, the scales for the bending, tension and gravitational pressure terms in (2.3) are

$L$, the scales for the bending, tension and gravitational pressure terms in (2.3) are

respectively. Balancing these pairwise reveals three key length scales which we term the bending–tension length, the bending–gravity length and the tension–gravity length, respectively,

These length scales are analogous to the capillary length ![]() $(\gamma /\rho g)^{1/2}$ for capillary spreading. The bending term dominates on small length scales (

$(\gamma /\rho g)^{1/2}$ for capillary spreading. The bending term dominates on small length scales (![]() $L \ll {L_{BT}}, {L_{BG}}$), the gravity term dominates on large length scales (

$L \ll {L_{BT}}, {L_{BG}}$), the gravity term dominates on large length scales (![]() $L \gg {L_{BG}}, {L_{TG}}$) and the tension term dominates on medium length scales (

$L \gg {L_{BG}}, {L_{TG}}$) and the tension term dominates on medium length scales (![]() ${L_{BT}} \ll L \ll {L_{TG}}$, if this interval exists).

${L_{BT}} \ll L \ll {L_{TG}}$, if this interval exists).

Since ![]() ${L_{BG}} = ({L_{BT}} {L_{TG}})^{1/2}$ lies between

${L_{BG}} = ({L_{BT}} {L_{TG}})^{1/2}$ lies between ![]() ${L_{BT}}$ and

${L_{BT}}$ and ![]() ${L_{TG}}$, the three transition lengths can only be ordered either as

${L_{TG}}$, the three transition lengths can only be ordered either as ![]() ${L_{TG}} \leq {L_{BG}} \leq {L_{BT}}$ or as

${L_{TG}} \leq {L_{BG}} \leq {L_{BT}}$ or as ![]() ${L_{BT}} \leq {L_{BG}} \leq {L_{TG}}$. Thus, there are two asymptotic limits to consider: If

${L_{BT}} \leq {L_{BG}} \leq {L_{TG}}$. Thus, there are two asymptotic limits to consider: If ![]() ${L_{TG}} \ll {L_{BG}} \ll {L_{BT}}$ (or equivalently

${L_{TG}} \ll {L_{BG}} \ll {L_{BT}}$ (or equivalently ![]() $T^2 \ll B\rho g$), then bending is dominant for

$T^2 \ll B\rho g$), then bending is dominant for ![]() $L \ll {L_{BG}}$ and gravity is dominant for

$L \ll {L_{BG}}$ and gravity is dominant for ![]() ${L_{BG}} \ll L$, as shown in figure 2(a), while tension is always negligible. On the other hand, if

${L_{BG}} \ll L$, as shown in figure 2(a), while tension is always negligible. On the other hand, if ![]() ${L_{BT}} \ll {L_{BG}} \ll {L_{TG}}$ (or equivalently

${L_{BT}} \ll {L_{BG}} \ll {L_{TG}}$ (or equivalently ![]() $T^2 \gg B\rho g$), then bending is dominant for

$T^2 \gg B\rho g$), then bending is dominant for ![]() $L \ll {L_{BT}}$, tension is dominant for

$L \ll {L_{BT}}$, tension is dominant for ![]() ${L_{BT}} \ll L \ll {L_{TG}}$, and gravity is dominant for

${L_{BT}} \ll L \ll {L_{TG}}$, and gravity is dominant for ![]() ${L_{TG}} \ll L$, as shown in figure 2(b).

${L_{TG}} \ll L$, as shown in figure 2(b).

At any given time, the horizontal length scales in the system span the range from the large blister radius ![]() $R(t)$ down to the small length scale

$R(t)$ down to the small length scale ![]() $\ell _{p}(t)$ of the peeling region (see § 4), which can be represented as a point

$\ell _{p}(t)$ of the peeling region (see § 4), which can be represented as a point ![]() $(R, \ell _{p})$ in a two-dimensional regime diagram (figure 2). The diagram can then be divided into regimes according to which forces are dominant, which is determined by how

$(R, \ell _{p})$ in a two-dimensional regime diagram (figure 2). The diagram can then be divided into regimes according to which forces are dominant, which is determined by how ![]() $\ell _{p}$ and

$\ell _{p}$ and ![]() $R$ compare to the transition lengths

$R$ compare to the transition lengths ![]() ${L_{BT}}$,

${L_{BT}}$, ![]() ${L_{BG}}$ and

${L_{BG}}$ and ![]() ${L_{TG}}$.

${L_{TG}}$.

In figure 2(a), for example, if both ![]() $\ell _{p}$ and

$\ell _{p}$ and ![]() $R$ are smaller than

$R$ are smaller than ![]() ${L_{BG}}$, then all length scales in the system are too, so only bending forces are dominant. We refer to this regime as the ‘pure’ bending regime. Similarly, if both are larger than

${L_{BG}}$, then all length scales in the system are too, so only bending forces are dominant. We refer to this regime as the ‘pure’ bending regime. Similarly, if both are larger than ![]() ${L_{BG}}$, then only gravity is dominant. However, if

${L_{BG}}$, then only gravity is dominant. However, if ![]() $\ell _{p} \ll {L_{BG}} \ll R$, then bending is dominant in the parts of the system where the length scale is

$\ell _{p} \ll {L_{BG}} \ll R$, then bending is dominant in the parts of the system where the length scale is ![]() $\ll {L_{BG}}$, while gravity is dominant in the parts where the length scale is

$\ll {L_{BG}}$, while gravity is dominant in the parts where the length scale is ![]() $\gg {L_{BG}}$, so we have a ‘hybrid’ bending–gravity regime.

$\gg {L_{BG}}$, so we have a ‘hybrid’ bending–gravity regime.

Since the fluid spreads and ![]() $R(t)$ increases with time, the system moves towards the right in the regime diagram (figure 2). For ease of discussion, we focus on the case where

$R(t)$ increases with time, the system moves towards the right in the regime diagram (figure 2). For ease of discussion, we focus on the case where ![]() $\ell _{p}(t)$ also increases with time, so that the system also moves upwards in the diagram. We shall see that this case corresponds to a decreasing peeling speed

$\ell _{p}(t)$ also increases with time, so that the system also moves upwards in the diagram. We shall see that this case corresponds to a decreasing peeling speed ![]() $\dot R$ and thus to a condition that the injection exponent

$\dot R$ and thus to a condition that the injection exponent ![]() $\beta$ is not too large. (For sufficiently large

$\beta$ is not too large. (For sufficiently large ![]() $\beta$,

$\beta$, ![]() $\dot R$ increases and

$\dot R$ increases and ![]() $\ell _p(t)$ decreases with time, and the system moves downwards in the diagram instead.) Moving rightwards and upwards in the diagram, the system generally evolves from being purely bending dominated at very early times to being purely gravity dominated at very late times, passing through a number of intervening hybrid, or possibly tension-dominated, regimes at intermediate times.

$\ell _p(t)$ decreases with time, and the system moves downwards in the diagram instead.) Moving rightwards and upwards in the diagram, the system generally evolves from being purely bending dominated at very early times to being purely gravity dominated at very late times, passing through a number of intervening hybrid, or possibly tension-dominated, regimes at intermediate times.

Since ![]() $R(t)$ and

$R(t)$ and ![]() $\ell _{p}(t)$ are not known a priori, our approach is to solve for each regime first, before determining its temporal range of validity. In § 4 we analyse the peeling region on the scale

$\ell _{p}(t)$ are not known a priori, our approach is to solve for each regime first, before determining its temporal range of validity. In § 4 we analyse the peeling region on the scale ![]() $\ell _{p}$, and in § 5 we analyse the blister shape and determine the spreading law

$\ell _{p}$, and in § 5 we analyse the blister shape and determine the spreading law ![]() $R(t)$ in the various regimes.

$R(t)$ in the various regimes.

4. Travelling-wave peeling solutions

We consider the asymptotic limit ![]() $h_0 \ll {H}$ where the pre-wetting layer is very thin relative to the thickness of the fluid that has been injected. This results in different parts of the system having asymptotically different scales, as shown in figure 3. The blister

$h_0 \ll {H}$ where the pre-wetting layer is very thin relative to the thickness of the fluid that has been injected. This results in different parts of the system having asymptotically different scales, as shown in figure 3. The blister ![]() $x < R$ (or

$x < R$ (or ![]() $r < R$) is the largest region, with height

$r < R$) is the largest region, with height ![]() ${H}(t)$ and radius

${H}(t)$ and radius ![]() $R(t)$. Near its edge

$R(t)$. Near its edge ![]() $x \approx R$ (or

$x \approx R$ (or ![]() $r \approx R$) at the apparent contact line we expect to find a peeling region with height scale

$r \approx R$) at the apparent contact line we expect to find a peeling region with height scale ![]() $h_0 \ll {H}$ and some length scale

$h_0 \ll {H}$ and some length scale ![]() $\ell _{p}(t) \ll R$ to be determined.

$\ell _{p}(t) \ll R$ to be determined.

Figure 3. Schematic figure of the asymptotic structure. The large blister has a small peeling region at its edge ![]() $x=R$ or

$x=R$ or ![]() $r=R$. For the hybrid cases where multiple driving forces are dominant, the peeling region is nested inside an intermediate region (dashed arrows). The variables

$r=R$. For the hybrid cases where multiple driving forces are dominant, the peeling region is nested inside an intermediate region (dashed arrows). The variables ![]() $h_{b}$,

$h_{b}$, ![]() $h_{p}$ and

$h_{p}$ and ![]() $h_{i}$ and local coordinates

$h_{i}$ and local coordinates ![]() $x_{p}$ and

$x_{p}$ and ![]() $x_{i}$ are used to describe the leading-order asymptotic solutions in each region.

$x_{i}$ are used to describe the leading-order asymptotic solutions in each region.

In the peeling region, we define the leading-order solution ![]() $h = h_{p}(x_{p})$, where

$h = h_{p}(x_{p})$, where ![]() $x_{p} = R(t) - x$ or

$x_{p} = R(t) - x$ or ![]() $x_{p} = R(t) - r$ is an inward-pointing local coordinate. The scaling

$x_{p} = R(t) - r$ is an inward-pointing local coordinate. The scaling ![]() $x_{p} \sim \ell _{p} \ll R$ allows two approximations. Firstly, regardless of the global geometry (2-D or axi), the leading-order local peeling process is two-dimensional, with no variation in the horizontal direction transverse to the direction of motion. Secondly, in the time derivative

$x_{p} \sim \ell _{p} \ll R$ allows two approximations. Firstly, regardless of the global geometry (2-D or axi), the leading-order local peeling process is two-dimensional, with no variation in the horizontal direction transverse to the direction of motion. Secondly, in the time derivative ![]() $\partial h/\partial t = \partial h_{p}/\partial t + \dot R\,\partial h_{p}/\partial x_{p}$ the second term, due to the outward spreading motion, is dominant by a factor of order

$\partial h/\partial t = \partial h_{p}/\partial t + \dot R\,\partial h_{p}/\partial x_{p}$ the second term, due to the outward spreading motion, is dominant by a factor of order ![]() $R/\ell _{p}$ (assuming that

$R/\ell _{p}$ (assuming that ![]() $\dot R \sim R/t$). Neglecting the first term allows the governing equation (2.4b) to be integrated once, with far-field condition

$\dot R \sim R/t$). Neglecting the first term allows the governing equation (2.4b) to be integrated once, with far-field condition ![]() $h_{p}(-\infty) = h_0$, to yield the travelling-wave equation

$h_{p}(-\infty) = h_0$, to yield the travelling-wave equation

Given the value of ![]() $\dot R$, the peeling length scale

$\dot R$, the peeling length scale ![]() $\ell _{p}$ is determined by balancing the terms on the left-hand side with the relevant term or terms on the right-hand side. If one of the three terms is dominant, then

$\ell _{p}$ is determined by balancing the terms on the left-hand side with the relevant term or terms on the right-hand side. If one of the three terms is dominant, then ![]() $\ell _{p}$ is given by one of the expressions

$\ell _{p}$ is given by one of the expressions

\begin{equation} \ell_{{p}{B}} = \left(\frac{B h_0^3}{12\mu \dot R}\right)^{1/5}, \quad \ell_{{p}{T}} = \left(\frac{T h_0^3}{12\mu \dot R}\right)^{1/3}, \quad \ell_{{p}{G}} = \frac{\rho g h_0^3}{12\mu \dot R}. \end{equation}

\begin{equation} \ell_{{p}{B}} = \left(\frac{B h_0^3}{12\mu \dot R}\right)^{1/5}, \quad \ell_{{p}{T}} = \left(\frac{T h_0^3}{12\mu \dot R}\right)^{1/3}, \quad \ell_{{p}{G}} = \frac{\rho g h_0^3}{12\mu \dot R}. \end{equation}

Which of these expressions is the relevant one is determined by comparing them to the transition length scales (3.2). For example, if ![]() $\dot R$ is very large, then all the options in (4.2) are smaller than

$\dot R$ is very large, then all the options in (4.2) are smaller than ![]() ${L_{BG}}$ and

${L_{BG}}$ and ![]() ${L_{BT}}$, so the only self-consistent possibility is that bending is dominant and

${L_{BT}}$, so the only self-consistent possibility is that bending is dominant and ![]() $\ell _{p} = \ell _{{p}{B}}$. As

$\ell _{p} = \ell _{{p}{B}}$. As ![]() $\dot R$ decreases, the length scales all increase and either tension becomes dominant instead due to both

$\dot R$ decreases, the length scales all increase and either tension becomes dominant instead due to both ![]() $\ell _{{p}{B}}$ and

$\ell _{{p}{B}}$ and ![]() $\ell _{{p}{T}}$ crossing

$\ell _{{p}{T}}$ crossing ![]() ${L_{BT}}$, leading to

${L_{BT}}$, leading to ![]() $\ell _{p} = \ell _{{p}{T}}$, or gravity becomes dominant instead due to both

$\ell _{p} = \ell _{{p}{T}}$, or gravity becomes dominant instead due to both ![]() $\ell _{{p}{B}}$ and

$\ell _{{p}{B}}$ and ![]() $\ell _{{p}{G}}$ crossing

$\ell _{{p}{G}}$ crossing ![]() ${L_{BG}}$, leading to

${L_{BG}}$, leading to ![]() $\ell _{p} = \ell _{{p}{G}}$.

$\ell _{p} = \ell _{{p}{G}}$.

When a single term on the right-hand side of (4.1) is dominant, we can introduce the non-dimensionalization ![]() $h_{p} = h_0 F(X \equiv x_{p}/\ell _{p})$, which yields the travelling-wave equations

$h_{p} = h_0 F(X \equiv x_{p}/\ell _{p})$, which yields the travelling-wave equations

for bending, tension and gravity, respectively. These are supplemented by the far-field condition and a choice of origin

from (2.5a) and (2.1b), respectively, as well as suitable matching conditions to the blister as ![]() $X \to \infty$, as stated below.

$X \to \infty$, as stated below.

4.1. Peeling by bending

For the fifth-order peeling-by-bending equation (4.3a), the condition (4.4a) excludes two growing solutions and (4.4b) is a third condition, so we can further impose the two far-field conditions

which excludes the generic quartic growth of solutions to (4.3a) in favour of a slower quadratic growth. This yields a unique solution, which can be calculated numerically (Lister et al. Reference Lister, Peng and Neufeld2013) and is shown in figure 4(a). The solution has a quadratic far-field behaviour ![]() $F'' \to C_{p}$ as

$F'' \to C_{p}$ as ![]() $X \to \infty$, with

$X \to \infty$, with ![]() $C_{p} \approx 1.350507$. In order to match, the leading-order blister solution

$C_{p} \approx 1.350507$. In order to match, the leading-order blister solution ![]() $h = h_{b}$ must also have a quadratic behaviour near the apparent contact line, i.e. satisfy clamped conditions and have a non-zero curvature

$h = h_{b}$ must also have a quadratic behaviour near the apparent contact line, i.e. satisfy clamped conditions and have a non-zero curvature ![]() $\kappa$,

$\kappa$,

(These conditions are seen in § 5 to yield a unique solution for the blister, and matching to a different peeling solution with quartic or cubic far-field behaviour would not be possible.) Matching the curvature at the edge of the blister to that of the peeling solution yields

\begin{equation} \kappa = C_{p} \frac{h_0}{\ell_{{p}{B}}^2} \Rightarrow \dot R = 0.471800 \frac{B h_0^{1/2}}{12\mu} \kappa^{5/2}, \end{equation}

\begin{equation} \kappa = C_{p} \frac{h_0}{\ell_{{p}{B}}^2} \Rightarrow \dot R = 0.471800 \frac{B h_0^{1/2}}{12\mu} \kappa^{5/2}, \end{equation}from (4.2a), as stated in (1.1a).

Figure 4. Asymptotic travelling-wave peeling solutions for (a) bending (showing the rescaled height ![]() $F$, curvature

$F$, curvature ![]() $F''$ and pressure

$F''$ and pressure ![]() $F''''$), (b) tension (showing the rescaled height

$F''''$), (b) tension (showing the rescaled height ![]() $F$, slope

$F$, slope ![]() $F'$ and pressure

$F'$ and pressure ![]() $-F''$) and (c) gravity (showing the rescaled height or pressure

$-F''$) and (c) gravity (showing the rescaled height or pressure ![]() $F$).

$F$).

4.2. Peeling by pulling

For the third-order peeling-by-pulling equation (4.3b), the condition (4.4a) excludes one growing solution and (4.4b) is a second condition, so we can further impose (in analogy with (4.5)) the one condition that

This yields a unique solution, which can be calculated numerically and is shown in figure 4(b). The leading-order far-field behaviour can be determined analytically from the large-![]() $F$ approximation of (4.3b),

$F$ approximation of (4.3b), ![]() $1 \approx -F^2 F'''$, as

$1 \approx -F^2 F'''$, as

The far-field slope ![]() $F'$ varies with

$F'$ varies with ![]() $X$, but logarithmically slowly, so, in matching with the blister region with length scale

$X$, but logarithmically slowly, so, in matching with the blister region with length scale ![]() $R$, we can use the value of

$R$, we can use the value of ![]() $F'$ evaluated at

$F'$ evaluated at ![]() $X = R/\ell _{{p}{T}}$.

$X = R/\ell _{{p}{T}}$.

In order for the blister solution to match the approximately linear behaviour (4.9), we require zero height and a non-zero slope ![]() $\alpha$ near the contact line,

$\alpha$ near the contact line,

Comparison with (4.9) evaluated at ![]() $X = R/\ell _{{p}{T}}$ yields

$X = R/\ell _{{p}{T}}$ yields

\begin{equation} \alpha = \left(3 \ln \frac{R}{\ell_{{p}{T}}}\right)^{1/3} \frac{h_0}{\ell_{{p}{T}}} \Rightarrow \dot R = \frac{T \alpha^3}{12\mu\,\ln[(R/\ell_{{p}{T}})^3]}, \end{equation}

\begin{equation} \alpha = \left(3 \ln \frac{R}{\ell_{{p}{T}}}\right)^{1/3} \frac{h_0}{\ell_{{p}{T}}} \Rightarrow \dot R = \frac{T \alpha^3}{12\mu\,\ln[(R/\ell_{{p}{T}})^3]}, \end{equation}

as given in (1.1b). This expression has a weak logarithmic dependence on ![]() $\ell _{{p}{T}}$ and hence on

$\ell _{{p}{T}}$ and hence on ![]() $\dot R$. In order to solve for

$\dot R$. In order to solve for ![]() $\dot R$ explicitly, we can make use of the Lambert

$\dot R$ explicitly, we can make use of the Lambert ![]() $W$-function, which we denote by

$W$-function, which we denote by ![]() $\ln _*(x)$ due to its similarity with

$\ln _*(x)$ due to its similarity with ![]() $\ln (x)$. This is defined by

$\ln (x)$. This is defined by

We then obtain, from (4.11) and (4.2b),

4.3. Peeling by gravitational spreading

For the first-order gravity-current equation (4.3c), the peeling process is simply gravitational spreading of the fluid under the sheet. The general solution is given implicitly by

which automatically satisfies the condition (4.4a) leaving only the choice of origin ![]() $X_0$. In this case, the origin cannot be chosen using (4.4b) since

$X_0$. In this case, the origin cannot be chosen using (4.4b) since ![]() $F>1$ everywhere (the solution approaches

$F>1$ everywhere (the solution approaches ![]() $F=1$ monotonically rather than in an oscillatory manner as

$F=1$ monotonically rather than in an oscillatory manner as ![]() $X \to -\infty$), but we can instead choose, for example,

$X \to -\infty$), but we can instead choose, for example, ![]() $F(0) = 1.1$, which corresponds to

$F(0) = 1.1$, which corresponds to ![]() $X_0 \approx 0.154$. This solution is shown in figure 4(c).

$X_0 \approx 0.154$. This solution is shown in figure 4(c).

For matching with the blister solution, we would expect, by analogy with the bending and tension cases, to use just the height ![]() $F$. Requiring

$F$. Requiring ![]() $h_{b}$ to match the cube-root behaviour

$h_{b}$ to match the cube-root behaviour ![]() $F \sim (3X)^{1/3}$ as

$F \sim (3X)^{1/3}$ as ![]() $X \to \infty$ yields

$X \to \infty$ yields

which describes conservation of flux at the apparent contact line.

5. Quasi-static blister solutions and resulting spreading rates

For peeling by bending (4.7) and peeling by pulling (4.13), the peeling speed ![]() $\dot R$ decreases as

$\dot R$ decreases as ![]() $h_0$ decreases, and a posteriori scaling analyses (see § 7) show that if

$h_0$ decreases, and a posteriori scaling analyses (see § 7) show that if ![]() $h_0 \ll {H}$ then the spreading is sufficiently slow that the pressure drop in the bulk of the large blister is asymptotically negligible. The large blister region then evolves quasi-statically and its shape can be determined analytically. In this section, we perform these calculations and use (4.7) and (4.13) to obtain the spreading rate

$h_0 \ll {H}$ then the spreading is sufficiently slow that the pressure drop in the bulk of the large blister is asymptotically negligible. The large blister region then evolves quasi-statically and its shape can be determined analytically. In this section, we perform these calculations and use (4.7) and (4.13) to obtain the spreading rate ![]() $R(t)$ in the various regimes shown in the regime diagrams in figure 2 (but restricted to the unshaded areas). We also discuss the non-quasi-static gravity-dominated case in § 5.8.

$R(t)$ in the various regimes shown in the regime diagrams in figure 2 (but restricted to the unshaded areas). We also discuss the non-quasi-static gravity-dominated case in § 5.8.

5.1. The general blister solution

We assume that the viscous pressure drop in the bulk of the blister is asymptotically negligible, and hence the pressure in the blister is spatially uniform, ![]() $p = p_{b}(t)$, to leading order. Equivalently, pressure variations in the blister region are quickly equilibrated, owing to the large mobility

$p = p_{b}(t)$, to leading order. Equivalently, pressure variations in the blister region are quickly equilibrated, owing to the large mobility ![]() $h^3/12\mu$ in the blister, and hence on the much slower time scale of spreading the pressure is approximately uniform.

$h^3/12\mu$ in the blister, and hence on the much slower time scale of spreading the pressure is approximately uniform.

The asymptotic leading-order blister solution ![]() $h = h_{b}$ is thus obtained by solving the equation

$h = h_{b}$ is thus obtained by solving the equation

(where some of the terms on the right-hand side may be negligible) with a simplified volume constraint (2.6),

symmetry conditions (2.5b),

and suitable matching conditions to the peeling solution at the apparent contact line ![]() $x=R$ or

$x=R$ or ![]() $r=R$ as follows.

$r=R$ as follows.

For peeling by bending (§ 4.1), where the fourth-order bending term in (5.1) is dominant near the contact line, we use the conditions ![]() $h_{b}(R) = h_{b}'(R) = 0$ from (4.6). For peeling by pulling (§ 4.2), where the second-order tension term in (5.1) is dominant near the contact line (and hence the fourth-order term is negligible everywhere), we use the condition

$h_{b}(R) = h_{b}'(R) = 0$ from (4.6). For peeling by pulling (§ 4.2), where the second-order tension term in (5.1) is dominant near the contact line (and hence the fourth-order term is negligible everywhere), we use the condition ![]() $h_{b}(R) = 0$ from (4.10). Finally, if gravity is dominant near the contact line (§ 4.3), then it turns out that the blister is not quasi-static (see § 5.8).

$h_{b}(R) = 0$ from (4.10). Finally, if gravity is dominant near the contact line (§ 4.3), then it turns out that the blister is not quasi-static (see § 5.8).

The general solutions of the blister equations (5.1)–(5.3) with these boundary conditions involve hyperbolic or Bessel functions. The expressions are given in appendix B and some representative results are shown in figure 5. The solutions yield the curvature ![]() $\kappa$ or slope

$\kappa$ or slope ![]() $\alpha$ at the edge of the blister in terms of

$\alpha$ at the edge of the blister in terms of ![]() $R$,

$R$, ![]() $t$ and the parameters of the system, which when combined with the peeling-by-bending (4.7) or peeling-by-pulling (4.13) law for

$t$ and the parameters of the system, which when combined with the peeling-by-bending (4.7) or peeling-by-pulling (4.13) law for ![]() $\dot R$ can be integrated to yield

$\dot R$ can be integrated to yield ![]() $R(t)$. However, in order to understand the physics better, we solve the blister equations here using asymptotic methods in each of the regimes indicated in figure 2 to obtain the relevant values of

$R(t)$. However, in order to understand the physics better, we solve the blister equations here using asymptotic methods in each of the regimes indicated in figure 2 to obtain the relevant values of ![]() $\kappa$ or

$\kappa$ or ![]() $\alpha$ as well as power-law expressions for

$\alpha$ as well as power-law expressions for ![]() $R(t)$ in each regime.

$R(t)$ in each regime.

Figure 5. Representative two-dimensional quasi-static blister height profiles, comparing the full solutions (B 1) and (B 2) (solid curves) and the asymptotic solutions (dashed curves). The regime name, subsection and values of ![]() $({L_{BT}}/R,{L_{BG}}/R,{L_{TG}}/R)$ for each case are (a) ‘

$({L_{BT}}/R,{L_{BG}}/R,{L_{TG}}/R)$ for each case are (a) ‘![]() $B$’, § 5.2, (5,5,5); (b) ‘

$B$’, § 5.2, (5,5,5); (b) ‘![]() $T$’, § 5.3, (0,0,5); (c) ‘

$T$’, § 5.3, (0,0,5); (c) ‘![]() $B+T$’, § 5.4, (0.1,1,10); (d) ‘

$B+T$’, § 5.4, (0.1,1,10); (d) ‘![]() $T+G$’, § 5.5, (0,0,0.1); (e) ‘

$T+G$’, § 5.5, (0,0,0.1); (e) ‘![]() $B+G$’, § 5.6, (0.01,0.1,1); (f) ‘

$B+G$’, § 5.6, (0.01,0.1,1); (f) ‘![]() $B+T+G$’, § 5.7, (0.04,

$B+T+G$’, § 5.7, (0.04,![]() $0.2^{3/2}$,0.2). The asymptotic solutions are given by the main blister solutions (5.4), (5.6) and composites (5.11), (5.14), (5.16) and (5.18). The letters indicate which term dominates in the bulk of the blister, in the peeling region, and in an intermediate region (if present). The key quantities – curvature

$0.2^{3/2}$,0.2). The asymptotic solutions are given by the main blister solutions (5.4), (5.6) and composites (5.11), (5.14), (5.16) and (5.18). The letters indicate which term dominates in the bulk of the blister, in the peeling region, and in an intermediate region (if present). The key quantities – curvature ![]() $\kappa = h''$ (associated with bending), slope

$\kappa = h''$ (associated with bending), slope ![]() $\alpha = -h'$ (associated with tension) and height

$\alpha = -h'$ (associated with tension) and height ![]() $\zeta = h$ (associated with gravity) – are labelled.

$\zeta = h$ (associated with gravity) – are labelled.

5.2. Bending only (regime ‘ $B$’)

$B$’)

First, if ![]() $R \ll {L_{BG}},{L_{BT}}$ then bending is dominant everywhere and (5.1) reduces to

$R \ll {L_{BG}},{L_{BT}}$ then bending is dominant everywhere and (5.1) reduces to ![]() $p_{b} = B\nabla ^4 h_{b}$. Together with (5.2), (5.3) and (4.6), this yields the blister profile

$p_{b} = B\nabla ^4 h_{b}$. Together with (5.2), (5.3) and (4.6), this yields the blister profile ![]() $h_{b}$, pressure

$h_{b}$, pressure ![]() $p_{b}$ and peeling curvature

$p_{b}$ and peeling curvature ![]() $\kappa = h_{b}''(R)$ as

$\kappa = h_{b}''(R)$ as

\begin{gather} \text{2-D: } h_{b} = \frac{15}{8} \frac{V}{R} \left(1 - \frac{x^2}{R^2}\right)^2, \quad \frac{p_{b}}{B} = 45\frac{V}{R^5}, \quad \kappa = 15\frac{V}{R^3}, \end{gather}

\begin{gather} \text{2-D: } h_{b} = \frac{15}{8} \frac{V}{R} \left(1 - \frac{x^2}{R^2}\right)^2, \quad \frac{p_{b}}{B} = 45\frac{V}{R^5}, \quad \kappa = 15\frac{V}{R^3}, \end{gather} \begin{gather}\text{Axi: } h_{b} = \frac{3}{\pi} \frac{V}{R^2} \left(1 - \frac{r^2}{R^2}\right)^2, \quad \frac{p_{b}}{B} = \frac{192}{\pi} \frac{V}{R^6}, \quad \kappa = \frac{24}{\pi} \frac{V}{R^4}, \end{gather}

\begin{gather}\text{Axi: } h_{b} = \frac{3}{\pi} \frac{V}{R^2} \left(1 - \frac{r^2}{R^2}\right)^2, \quad \frac{p_{b}}{B} = \frac{192}{\pi} \frac{V}{R^6}, \quad \kappa = \frac{24}{\pi} \frac{V}{R^4}, \end{gather}in agreement with the sample solution of (B 1) shown in figure 5(a).

We substitute the curvature ![]() $\kappa$ into the peeling-by-bending law (4.7) and integrate the differential equation to find the spreading rate

$\kappa$ into the peeling-by-bending law (4.7) and integrate the differential equation to find the spreading rate

\begin{gather} \text{2-D: } \dot R = 411 \frac{B h_0^{1/2} Q^{5/2}t^{5\beta/2}}{12\mu R^{15/2}} \Rightarrow R(t) = 2.83\left(\frac{B^2 h_0 Q^5 t^{5\beta+2}}{(5\beta+2)^2 (12\mu)^2}\right)^{1/17}, \end{gather}

\begin{gather} \text{2-D: } \dot R = 411 \frac{B h_0^{1/2} Q^{5/2}t^{5\beta/2}}{12\mu R^{15/2}} \Rightarrow R(t) = 2.83\left(\frac{B^2 h_0 Q^5 t^{5\beta+2}}{(5\beta+2)^2 (12\mu)^2}\right)^{1/17}, \end{gather} \begin{gather}\text{Axi: } \dot R = 76.1\frac{B h_0^{1/2} Q^{5/2}t^{5\beta/2}}{12\mu R^{10}} \Rightarrow R(t) = 1.96\left(\frac{B^2 h_0 Q^5 t^{5\beta+2}}{(5\beta+2)^2 (12\mu)^2}\right)^{1/22}. \end{gather}

\begin{gather}\text{Axi: } \dot R = 76.1\frac{B h_0^{1/2} Q^{5/2}t^{5\beta/2}}{12\mu R^{10}} \Rightarrow R(t) = 1.96\left(\frac{B^2 h_0 Q^5 t^{5\beta+2}}{(5\beta+2)^2 (12\mu)^2}\right)^{1/22}. \end{gather}

In this case and the following ones, once the spreading rate ![]() $R(t)$ is known, the blister height

$R(t)$ is known, the blister height ![]() ${H}(t)$ and pressure

${H}(t)$ and pressure ![]() $p_{b}(t)$ can be calculated from the appropriate blister solution if required.

$p_{b}(t)$ can be calculated from the appropriate blister solution if required.

5.3. Tension only (regime ‘ $T$’)

$T$’)

If ![]() ${L_{BT}} \ll (R,\ell _{p}) \ll {L_{TG}}$, then tension is dominant everywhere. Equation (5.1) reduces to

${L_{BT}} \ll (R,\ell _{p}) \ll {L_{TG}}$, then tension is dominant everywhere. Equation (5.1) reduces to ![]() $p_{b} = -T\nabla ^2 h_{b}$, which is of lower order than (5.1), so we can only impose a single symmetry condition

$p_{b} = -T\nabla ^2 h_{b}$, which is of lower order than (5.1), so we can only impose a single symmetry condition ![]() $h_{b}'(0) = 0$, together with

$h_{b}'(0) = 0$, together with ![]() $h_{b}(R) = 0$. The solution, which has a slope

$h_{b}(R) = 0$. The solution, which has a slope ![]() $\alpha = -h_{b}'(R)$ at the edge, is

$\alpha = -h_{b}'(R)$ at the edge, is

in agreement with figure 5(b).

Substitution of ![]() $\alpha$ into the peeling-by-pulling law (4.13) yields a differential equation for

$\alpha$ into the peeling-by-pulling law (4.13) yields a differential equation for ![]() $R(t)$, which can be integrated at leading order by approximating the logarithmic factor

$R(t)$, which can be integrated at leading order by approximating the logarithmic factor ![]() $\ln _*$ in (4.13) as a constant. The leading-order result is

$\ln _*$ in (4.13) as a constant. The leading-order result is

\begin{gather} \text{2-D: } R(t) = 2.29\left(\frac{T Q^3 t^{3\beta+1}}{(3\beta+1) 12\mu\,\ln_*[(12\mu Q^{4} t^{4\beta-1}/T h_0^{7})^{3/4}]}\right)^{1/7}, \end{gather}

\begin{gather} \text{2-D: } R(t) = 2.29\left(\frac{T Q^3 t^{3\beta+1}}{(3\beta+1) 12\mu\,\ln_*[(12\mu Q^{4} t^{4\beta-1}/T h_0^{7})^{3/4}]}\right)^{1/7}, \end{gather} \begin{gather}\text{Axi: } R(t) = 1.48\left(\frac{T Q^3 t^{3\beta+1}}{(3\beta+1)12\mu\,\ln_*[(12\mu Q^{2}t^{2\beta-1}/T h_0^{5})^{3/2}]}\right)^{1/10}. \end{gather}

\begin{gather}\text{Axi: } R(t) = 1.48\left(\frac{T Q^3 t^{3\beta+1}}{(3\beta+1)12\mu\,\ln_*[(12\mu Q^{2}t^{2\beta-1}/T h_0^{5})^{3/2}]}\right)^{1/10}. \end{gather}

We have neglected an ![]() $O(1)$ numerical factor inside the argument of each

$O(1)$ numerical factor inside the argument of each ![]() $\ln _*$ in (5.7) as it represents only a higher-order correction. Determining the values of these

$\ln _*$ in (5.7) as it represents only a higher-order correction. Determining the values of these ![]() $O(1)$ factors requires not only more careful integration of the differential equation, but also evaluation of corrections to the blister solution (due to the viscous pressure drop in the blister) and to the far-field behaviour of the peeling solution; the details are somewhat complicated and are given in appendix C.

$O(1)$ factors requires not only more careful integration of the differential equation, but also evaluation of corrections to the blister solution (due to the viscous pressure drop in the blister) and to the far-field behaviour of the peeling solution; the details are somewhat complicated and are given in appendix C.

5.4. Bending and tension (regime ‘ $B+T$’)

$B+T$’)

When ![]() $\ell _{p} \ll {L_{BT}} \ll R \ll {L_{TG}}$, bending is dominant on the peeling length scale

$\ell _{p} \ll {L_{BT}} \ll R \ll {L_{TG}}$, bending is dominant on the peeling length scale ![]() $\ell _{p} = \ell _{{p}{B}}$, while tension is dominant on main scale

$\ell _{p} = \ell _{{p}{B}}$, while tension is dominant on main scale ![]() $R$ of the blister. Hence, the peeling-by-bending solution (4.7) and the tension-dominated blister solution (5.6) apply. Since this blister solution has a non-zero slope

$R$ of the blister. Hence, the peeling-by-bending solution (4.7) and the tension-dominated blister solution (5.6) apply. Since this blister solution has a non-zero slope ![]() $\alpha = -h'(R)$, it does not satisfy the clamping condition

$\alpha = -h'(R)$, it does not satisfy the clamping condition ![]() $h'(R) = 0$ required for direct matching, so there must be an intermediate region near the apparent contact line, on the length scale

$h'(R) = 0$ required for direct matching, so there must be an intermediate region near the apparent contact line, on the length scale ![]() ${L_{BT}}$ where tension and bending balance.

${L_{BT}}$ where tension and bending balance.

For the intermediate solution, we define the leading-order solution ![]() $h_{i}$ and local coordinate

$h_{i}$ and local coordinate ![]() $x_{i}$ (which is equal to

$x_{i}$ (which is equal to ![]() $x_{p}$) by

$x_{p}$) by

In the blister equation (5.1), the constant pressure ![]() $p_{b} \sim T \alpha /R$ is set by the main solution (5.6). This pressure is negligible on the intermediate scale, where the bending and tension terms are much larger, scaling like

$p_{b} \sim T \alpha /R$ is set by the main solution (5.6). This pressure is negligible on the intermediate scale, where the bending and tension terms are much larger, scaling like ![]() $T\alpha /{L_{BT}}$ (from

$T\alpha /{L_{BT}}$ (from ![]() $x_{i} \sim {L_{BT}} \ll R$ and

$x_{i} \sim {L_{BT}} \ll R$ and ![]() $h_{i} \sim \alpha x_{i}$). Thus, the leading-order problem on the intermediate scale is

$h_{i} \sim \alpha x_{i}$). Thus, the leading-order problem on the intermediate scale is

representing the role of bending in effecting the transition from clamped conditions at ![]() $x_{i} = 0$ to a non-zero slope

$x_{i} = 0$ to a non-zero slope ![]() $\alpha$ as

$\alpha$ as ![]() $x_{i} \to \infty$. The unique solution of (5.9) is (e.g. Lister et al. Reference Lister, Peng and Neufeld2013)

$x_{i} \to \infty$. The unique solution of (5.9) is (e.g. Lister et al. Reference Lister, Peng and Neufeld2013)

For comparison with the full solution (B 1), we can form composite solutions of (5.6) and (5.10). For the two-dimensional case, after rescaling by the blister height, the additive composite is given by

and is in good agreement with the full solution, as shown in figure 5(c). The axisymmetric case can be treated similarly.

The effect of the bending–tension intermediate solution is to convert the slope ![]() $\alpha$ given by the main blister solution (5.6) to a curvature

$\alpha$ given by the main blister solution (5.6) to a curvature ![]() $\kappa = \alpha /{L_{BT}}$ that matches with the peeling region. Substitution into the peeling-by-bending law (4.7) yields, after integration,

$\kappa = \alpha /{L_{BT}}$ that matches with the peeling region. Substitution into the peeling-by-bending law (4.7) yields, after integration,

\begin{gather} \text{2-D: } R(t) = 2.11\left(\frac{T^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4(12\mu)^4 B}\right)^{1/24}, \end{gather}

\begin{gather} \text{2-D: } R(t) = 2.11\left(\frac{T^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4(12\mu)^4 B}\right)^{1/24}, \end{gather} \begin{gather}\text{Axi: } R(t) = 1.37\left(\frac{T^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4 (12\mu)^4 B}\right)^{1/34}. \end{gather}

\begin{gather}\text{Axi: } R(t) = 1.37\left(\frac{T^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4 (12\mu)^4 B}\right)^{1/34}. \end{gather}For this and the other hybrid solutions calculated below in § 5, the results only apply in the unshaded areas of the regime diagram (figure 2), as the assumption that the pressure is approximately uniform throughout the blister fails in the shaded areas. We discuss this issue further in § 7.

5.5. Tension and gravity (regime ‘ $T+G$’)

$T+G$’)

Gravity is dominant on the main scale ![]() $R$ of the blister if

$R$ of the blister if ![]() $R \gg {L_{BG}},{L_{TG}}$. This reduces (5.1) to the trivial equation

$R \gg {L_{BG}},{L_{TG}}$. This reduces (5.1) to the trivial equation ![]() $p_{b} = \rho g h_{b}$, resulting in a flat-topped profile with constant height

$p_{b} = \rho g h_{b}$, resulting in a flat-topped profile with constant height ![]() $\zeta$,

$\zeta$,

which again agrees with (B 1) and figure 5(d–f). However, this solution cannot match (4.6) or (4.10) directly.

If ![]() ${L_{BT}} \ll \ell _{{p}} \ll {L_{TG}} \ll R$, then tension dominates in the peeling region (while bending is negligible everywhere). At the edge of the gravity-dominated blister (5.13), there is need for a tension–gravity intermediate solution

${L_{BT}} \ll \ell _{{p}} \ll {L_{TG}} \ll R$, then tension dominates in the peeling region (while bending is negligible everywhere). At the edge of the gravity-dominated blister (5.13), there is need for a tension–gravity intermediate solution ![]() $h_{i}(x_{i})$ on the scale

$h_{i}(x_{i})$ on the scale ![]() ${L_{TG}}$, which satisfies

${L_{TG}}$, which satisfies ![]() $-T h_{i}'' + \rho g h_{i} = p_{b} = \rho g \zeta$ with the condition

$-T h_{i}'' + \rho g h_{i} = p_{b} = \rho g \zeta$ with the condition ![]() $h_{i}(0) = 0$ and the matching condition

$h_{i}(0) = 0$ and the matching condition ![]() $h_{i}(\infty) = \zeta$ to (5.13). The solution is

$h_{i}(\infty) = \zeta$ to (5.13). The solution is

which converts the height ![]() $\zeta$ into the slope

$\zeta$ into the slope ![]() $\alpha$, as illustrated in figure 5(d) (where (5.14) is used as asymptotic composite of (5.14) and (5.13), with a rescaling). Substitution of

$\alpha$, as illustrated in figure 5(d) (where (5.14) is used as asymptotic composite of (5.14) and (5.13), with a rescaling). Substitution of ![]() $\alpha$ into the peeling-by-pulling law (4.13) with the length scale

$\alpha$ into the peeling-by-pulling law (4.13) with the length scale ![]() ${L_{TG}}$ instead of

${L_{TG}}$ instead of ![]() $R$ in the argument of

$R$ in the argument of ![]() $\ln _*$ yields, after integration,

$\ln _*$ yields, after integration,

\begin{gather} \text{2-D: } R(t) = 2.00\left(\frac{(\rho g)^{3/2} T^{-1/2} Q^3 t^{3\beta+1}}{(3\beta+1)\,12\mu\,\ln_*[(12\mu)^3 T^{3/2} Q^3 t^{3\beta-3}/(\rho g)^{9/2}h_0^{12}]}\right)^{1/4}, \end{gather}

\begin{gather} \text{2-D: } R(t) = 2.00\left(\frac{(\rho g)^{3/2} T^{-1/2} Q^3 t^{3\beta+1}}{(3\beta+1)\,12\mu\,\ln_*[(12\mu)^3 T^{3/2} Q^3 t^{3\beta-3}/(\rho g)^{9/2}h_0^{12}]}\right)^{1/4}, \end{gather} \begin{gather}\text{Axi: } R(t) = 1.07 \left(\frac{(\rho g)^{3/2} T^{-1/2} Q^3 t^{3\beta+1}}{(3\beta+1)\,12\mu\,\ln_*[(12\mu)^6 T^3 Q^3 t^{3\beta-6}/(\rho g)^9 h_0^{21}]}\right)^{1/7}. \end{gather}

\begin{gather}\text{Axi: } R(t) = 1.07 \left(\frac{(\rho g)^{3/2} T^{-1/2} Q^3 t^{3\beta+1}}{(3\beta+1)\,12\mu\,\ln_*[(12\mu)^6 T^3 Q^3 t^{3\beta-6}/(\rho g)^9 h_0^{21}]}\right)^{1/7}. \end{gather}

(In this case, the next-order corrections due to the viscous pressure drop in the flat-topped part of the blister are of relative order ![]() $O(12\mu R^3/{H}^3 t)$, which turns out to be much greater than the effect of changing the argument of

$O(12\mu R^3/{H}^3 t)$, which turns out to be much greater than the effect of changing the argument of ![]() $\ln _*$ by a

$\ln _*$ by a ![]() $O(1)$ constant or indeed replacing

$O(1)$ constant or indeed replacing ![]() $\ln _*(\cdot)$ with

$\ln _*(\cdot)$ with ![]() $\ln (\cdot)$. Due to the effect to be discussed in § 7.1, this regime has a rather small range of validity, so we do not calculate the corrections in more detail.)

$\ln (\cdot)$. Due to the effect to be discussed in § 7.1, this regime has a rather small range of validity, so we do not calculate the corrections in more detail.)

5.6. Bending and gravity (regime ‘ $B+G$’)

$B+G$’)

If ![]() $\ell _{p} \ll {L_{BG}} \ll R$ and

$\ell _{p} \ll {L_{BG}} \ll R$ and ![]() $T^2 \ll \rho g B$ (figure 2a), then gravity dominates in the blister and bending dominates in the peeling region (while tension is negligible everywhere). This leads to a bending–gravity intermediate solution

$T^2 \ll \rho g B$ (figure 2a), then gravity dominates in the blister and bending dominates in the peeling region (while tension is negligible everywhere). This leads to a bending–gravity intermediate solution ![]() $h_{i}(x_{i})$ on the scale

$h_{i}(x_{i})$ on the scale ![]() $x_{i} \sim {L_{BG}}$, satisfying

$x_{i} \sim {L_{BG}}$, satisfying ![]() $B h_{i}'''' + \rho g h_{i} = p_{b} = \rho g \zeta$ with the clamped conditions

$B h_{i}'''' + \rho g h_{i} = p_{b} = \rho g \zeta$ with the clamped conditions ![]() $h_{i}(0) = h_{i}'(0) = 0$ and the matching condition

$h_{i}(0) = h_{i}'(0) = 0$ and the matching condition ![]() $h_{i}(\infty) = \zeta$. The unique solution is (e.g. Bunger & Cruden Reference Bunger and Cruden2011)

$h_{i}(\infty) = \zeta$. The unique solution is (e.g. Bunger & Cruden Reference Bunger and Cruden2011)

which converts the height ![]() $\zeta$ of the gravity-dominated blister solution (5.13) into a curvature

$\zeta$ of the gravity-dominated blister solution (5.13) into a curvature ![]() $\kappa$ at the edge as shown in figure 5(e) (where (5.16) is used as asymptotic composite of (5.16) and (5.13), with a rescaling).

$\kappa$ at the edge as shown in figure 5(e) (where (5.16) is used as asymptotic composite of (5.16) and (5.13), with a rescaling).

Substitution of (5.13) and (5.16) into the peeling-by-bending law (4.7) yields, after integration,

\begin{gather} \text{2-D: } R(t) = 1.41 \left(\frac{(\rho g)^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4(12\mu)^4 B}\right)^{1/14}, \end{gather}

\begin{gather} \text{2-D: } R(t) = 1.41 \left(\frac{(\rho g)^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4(12\mu)^4 B}\right)^{1/14}, \end{gather} \begin{gather}\text{Axi: } R(t) = 0.829 \left(\frac{(\rho g)^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4 (12\mu)^4 B}\right)^{1/24}. \end{gather}

\begin{gather}\text{Axi: } R(t) = 0.829 \left(\frac{(\rho g)^5 h_0^2 Q^{10} t^{10\beta+4}}{(5\beta+2)^4 (12\mu)^4 B}\right)^{1/24}. \end{gather}5.7. Bending, tension and gravity (regime ‘ $B+T+G$’)

$B+T+G$’)

If instead ![]() $T^2 \gg \rho g B$ (figure 2b), so that

$T^2 \gg \rho g B$ (figure 2b), so that ![]() $\ell _{p} \ll {L_{BT}} \ll {L_{TG}} \ll R$, then we obtain a nested hierarchy of intermediate solutions as shown in figure 5(f). The gravity-dominated blister (5.13) has a constant height

$\ell _{p} \ll {L_{BT}} \ll {L_{TG}} \ll R$, then we obtain a nested hierarchy of intermediate solutions as shown in figure 5(f). The gravity-dominated blister (5.13) has a constant height ![]() $\zeta$, a tension–gravity intermediate solution (5.14) converts

$\zeta$, a tension–gravity intermediate solution (5.14) converts ![]() $\zeta$ into the slope

$\zeta$ into the slope ![]() $\alpha = \zeta /{L_{TG}}$, and a bending–tension intermediate solution (5.10) converts

$\alpha = \zeta /{L_{TG}}$, and a bending–tension intermediate solution (5.10) converts ![]() $\alpha$ into the curvature

$\alpha$ into the curvature ![]() $\kappa = \alpha /{L_{BT}}$, which then feeds into the peeling-by-bending law (4.7). The two-dimensional asymptotic composite of (5.13), (5.14) and (5.10) shown in figure 5(f) is

$\kappa = \alpha /{L_{BT}}$, which then feeds into the peeling-by-bending law (4.7). The two-dimensional asymptotic composite of (5.13), (5.14) and (5.10) shown in figure 5(f) is

The relationship between ![]() $\kappa$ and

$\kappa$ and ![]() $\zeta$ is given by

$\zeta$ is given by ![]() $\kappa = \zeta /({L_{BT}} {L_{TG}}) = \zeta /{L_{BG}}^2$, which is the same as the bending–gravity result (5.16) without the intermediate tension. Hence, the spreading rate is again given by (5.17).

$\kappa = \zeta /({L_{BT}} {L_{TG}}) = \zeta /{L_{BG}}^2$, which is the same as the bending–gravity result (5.16) without the intermediate tension. Hence, the spreading rate is again given by (5.17).

5.8. Gravity only (regime ‘ $G$’)

$G$’)

If gravity dominates everywhere, then the quasi-static solution (5.13) does not apply: It clearly does not match the cube-root behaviour (4.15), and a scaling analysis reveals that the pressure gradient is not, in fact, negligible in the blister. Instead, there is a full leading-order balance in the lubrication equation (2.4) on the blister scale, with the condition that ![]() $h_{b} \to 0$ with conservation of flux (4.15) at the apparent contact line. At leading order, this yields the self-similar gravity-current solutions calculated by Huppert (Reference Huppert1982),

$h_{b} \to 0$ with conservation of flux (4.15) at the apparent contact line. At leading order, this yields the self-similar gravity-current solutions calculated by Huppert (Reference Huppert1982),

with the blister radius and height given by the power laws

\begin{gather} \text{2-D: } R(t)= A_1\left(\frac{\rho g Q^3 t^{3\beta+1}}{12\mu}\right)^{1/5},\quad {H}(t) = A_2 \left(\frac{12\mu\,Q^2 t^{2\beta-1}}{\rho g}\right)^{1/5}, \end{gather}

\begin{gather} \text{2-D: } R(t)= A_1\left(\frac{\rho g Q^3 t^{3\beta+1}}{12\mu}\right)^{1/5},\quad {H}(t) = A_2 \left(\frac{12\mu\,Q^2 t^{2\beta-1}}{\rho g}\right)^{1/5}, \end{gather} \begin{gather}\text{Axi: } R(t) = A_3\left(\frac{\rho g Q^3 t^{3\beta+1}}{12\mu}\right)^{1/8}, \quad {H}(t) = A_4 \left(\frac{12\mu\,Q t^{\beta-1}}{\rho g}\right)^{1/4}. \end{gather}

\begin{gather}\text{Axi: } R(t) = A_3\left(\frac{\rho g Q^3 t^{3\beta+1}}{12\mu}\right)^{1/8}, \quad {H}(t) = A_4 \left(\frac{12\mu\,Q t^{\beta-1}}{\rho g}\right)^{1/4}. \end{gather}

The profiles ![]() $\phi _{1,2}$ and the coefficients

$\phi _{1,2}$ and the coefficients ![]() $A_{1,2,3,4}$ depend on

$A_{1,2,3,4}$ depend on ![]() $\beta$ and are calculated numerically. At the apparent contact line, the nose of the gravity current (5.19) connects smoothly to the pre-wetting layer via the peeling solution (4.14).

$\beta$ and are calculated numerically. At the apparent contact line, the nose of the gravity current (5.19) connects smoothly to the pre-wetting layer via the peeling solution (4.14).

6. Comparison with numerical results

We solved the governing equations (2.3)–(2.7) numerically using a finite-difference method; see appendix A for details. For the numerical calculations, we non-dimensionalized the equations using the scale ![]() $h_0$ for

$h_0$ for ![]() $h$ and the bending scales

$h$ and the bending scales

\begin{gather} \text{2-D: } x_{B} = \left(\frac{B^\beta h_0^{3\beta+1}}{(12\mu)^\beta Q}\right)^{{1}/({6\beta-1})}, \quad t_{B} = \left(\frac{Bh_0^9}{12\mu Q^6}\right)^{{1}/({6\beta-1})}, \end{gather}

\begin{gather} \text{2-D: } x_{B} = \left(\frac{B^\beta h_0^{3\beta+1}}{(12\mu)^\beta Q}\right)^{{1}/({6\beta-1})}, \quad t_{B} = \left(\frac{Bh_0^9}{12\mu Q^6}\right)^{{1}/({6\beta-1})}, \end{gather} \begin{gather}\text{Axi: } x_{B} = \left(\frac{B^\beta h_0^{3\beta+1}}{(12\mu)^\beta Q}\right)^{{1}/({6\beta-2})}, \quad t_{B} = \left(\frac{B^2 h_0^{12}}{(12\mu)^2 Q^6}\right)^{{1}/({6\beta-2})}, \end{gather}

\begin{gather}\text{Axi: } x_{B} = \left(\frac{B^\beta h_0^{3\beta+1}}{(12\mu)^\beta Q}\right)^{{1}/({6\beta-2})}, \quad t_{B} = \left(\frac{B^2 h_0^{12}}{(12\mu)^2 Q^6}\right)^{{1}/({6\beta-2})}, \end{gather}

for ![]() $x$ or

$x$ or ![]() $r$ and

$r$ and ![]() $t$, respectively. These are obtained by balancing the pressure with the bending term in (2.3), i.e.

$t$, respectively. These are obtained by balancing the pressure with the bending term in (2.3), i.e. ![]() $p \sim B h/x^4$, and then balancing all the other terms in the remaining equations (2.4)–(2.7). The resulting non-dimensionalization is equivalent to setting

$p \sim B h/x^4$, and then balancing all the other terms in the remaining equations (2.4)–(2.7). The resulting non-dimensionalization is equivalent to setting ![]() $B = 12\mu = Q = h_0 = 1$ and replacing the tension and gravity coefficients

$B = 12\mu = Q = h_0 = 1$ and replacing the tension and gravity coefficients ![]() $T$ and

$T$ and ![]() $\rho g$ with non-dimensional versions

$\rho g$ with non-dimensional versions

both in the governing equations (2.3)–(2.7) and in the asymptotic results (§ 5). The coefficients ![]() $T_{B}$ and

$T_{B}$ and ![]() $G_{B}$ and the injection exponent

$G_{B}$ and the injection exponent ![]() $\beta$ form a complete set of three independent parameters for this system.

$\beta$ form a complete set of three independent parameters for this system.

We compare the asymptotic predictions for ![]() $R(t)$ from § 5 with the corresponding numerical results in figure 6 using a compensated log–log plot where

$R(t)$ from § 5 with the corresponding numerical results in figure 6 using a compensated log–log plot where ![]() $R(t)$ is divided by a suitable power of

$R(t)$ is divided by a suitable power of ![]() $t$ in order to highlight the difference between regimes. We focus on the fixed value

$t$ in order to highlight the difference between regimes. We focus on the fixed value ![]() $G_{B} = 10^{-32}$ for the non-dimensional gravity, and consider three different values

$G_{B} = 10^{-32}$ for the non-dimensional gravity, and consider three different values ![]() $T_{B} = 0,\ 10^{-10},\ 10^{-6}$ for the non-dimensional tension. These values have been chosen to be rather extreme, in order to allow the system to display clear transitions between the various regimes. We find that the transitions are very similar for the two-dimensional and axisymmetric cases, albeit with different exponents. The following discussion applies to both cases, and more generally to cases where the injection exponent

$T_{B} = 0,\ 10^{-10},\ 10^{-6}$ for the non-dimensional tension. These values have been chosen to be rather extreme, in order to allow the system to display clear transitions between the various regimes. We find that the transitions are very similar for the two-dimensional and axisymmetric cases, albeit with different exponents. The following discussion applies to both cases, and more generally to cases where the injection exponent ![]() $\beta$ is sufficiently small that

$\beta$ is sufficiently small that ![]() $\ell _{p}$ increases with time.

$\ell _{p}$ increases with time.

Figure 6. Numerical results (solid curves) and asymptotic solutions (dashed curves) for (a) two-dimensional spreading with injection exponent ![]() $\beta = 1$ and (b) axisymmetric spreading with injection exponent

$\beta = 1$ and (b) axisymmetric spreading with injection exponent ![]() $\beta = 1.5$. We use the bending scales (6.1) and fix

$\beta = 1.5$. We use the bending scales (6.1) and fix ![]() $\rho g = 10^{-32} B/x_{B}^4$, while considering three values for tension,

$\rho g = 10^{-32} B/x_{B}^4$, while considering three values for tension, ![]() $T = 0$,

$T = 0$, ![]() $T_1 = 10^{-10} B/x_{B}^2$ and

$T_1 = 10^{-10} B/x_{B}^2$ and ![]() $T_2 = 10^{-6} B/x_{B}^2$. The asymptotic results are labelled as in figures 2 and 5, with the subscripts indicating the value of

$T_2 = 10^{-6} B/x_{B}^2$. The asymptotic results are labelled as in figures 2 and 5, with the subscripts indicating the value of ![]() $T$. The radius

$T$. The radius ![]() $R(t)$ has been divided by the power of

$R(t)$ has been divided by the power of ![]() $t$ from the bending–tension hybrid regime (5.12) in order to show more clearly the differences between the regimes. The dotted lines indicate where

$t$ from the bending–tension hybrid regime (5.12) in order to show more clearly the differences between the regimes. The dotted lines indicate where ![]() $R$ is equal to one of the transition lengths (3.2).

$R$ is equal to one of the transition lengths (3.2).

Initially, since ![]() $T_{B} \ll 1$ and

$T_{B} \ll 1$ and ![]() $G_{B} \ll 1$ the system is bending dominated and follows the pure-bending spreading law (5.5), labelled ‘

$G_{B} \ll 1$ the system is bending dominated and follows the pure-bending spreading law (5.5), labelled ‘![]() $B$’.

$B$’.

For the case ![]() $T_{B} = 0$ (which corresponds to figure 2a), the bending-dominated regime lasts until the radius crosses

$T_{B} = 0$ (which corresponds to figure 2a), the bending-dominated regime lasts until the radius crosses ![]() ${L_{BG}} = 10^{-8}x_{B}$ (indicated by the dotted line). Then, gravitational forces become important and the system follows the bending–gravity hybrid solution (5.17), labelled ‘

${L_{BG}} = 10^{-8}x_{B}$ (indicated by the dotted line). Then, gravitational forces become important and the system follows the bending–gravity hybrid solution (5.17), labelled ‘![]() $B+G$’. Finally, the system transitions to the gravity-current spreading law (5.20), labelled ‘

$B+G$’. Finally, the system transitions to the gravity-current spreading law (5.20), labelled ‘![]() $G$’.

$G$’.

For the cases ![]() $T_{B} = 10^{-10}$ and

$T_{B} = 10^{-10}$ and ![]() $10^{-6}$ (which correspond to figure 2b), the system transitions from the pure-bending regime to the bending–tension hybrid regime (5.12), labelled ‘

$10^{-6}$ (which correspond to figure 2b), the system transitions from the pure-bending regime to the bending–tension hybrid regime (5.12), labelled ‘![]() $B+T_{1,2}$’, as

$B+T_{1,2}$’, as ![]() $R$ crosses

$R$ crosses ![]() ${L_{BT}}$. For

${L_{BT}}$. For ![]() $T_{B} = 10^{-10}$, when

$T_{B} = 10^{-10}$, when ![]() $R$ subsequently crosses

$R$ subsequently crosses ![]() ${L_{TG}}$ the system transitions to the bending–tension–gravity regime, whose spreading rate is the same as the bending–gravity regime (‘

${L_{TG}}$ the system transitions to the bending–tension–gravity regime, whose spreading rate is the same as the bending–gravity regime (‘![]() $B+G$’), and eventually into the gravity regime (‘

$B+G$’), and eventually into the gravity regime (‘![]() $G$’). For

$G$’). For ![]() $T_{B} = 10^{-6}$, the bending–tension regime gives way to the pure-tension regime (5.7), labelled ‘

$T_{B} = 10^{-6}$, the bending–tension regime gives way to the pure-tension regime (5.7), labelled ‘![]() $T_2$’. The system then follows the tension–gravity regime (5.15), labelled ‘

$T_2$’. The system then follows the tension–gravity regime (5.15), labelled ‘![]() $T_2+G$’, briefly before transitioning to the gravity regime (‘

$T_2+G$’, briefly before transitioning to the gravity regime (‘![]() $G$’).

$G$’).

We have thus exhibited all possible transitions shown in the regime diagrams in figure 2, and found excellent agreement between the numerical results and our asymptotic predictions. For less extreme, but still small, values of ![]() $T_{B}$ and

$T_{B}$ and ![]() $G_{B}$, the same transitions will happen but less clearly, while if one or both of

$G_{B}$, the same transitions will happen but less clearly, while if one or both of ![]() $T_{B}$ and

$T_{B}$ and ![]() $G_{B}$ is large then some of the earlier regimes involving bending might not occur. Also, for larger values of

$G_{B}$ is large then some of the earlier regimes involving bending might not occur. Also, for larger values of ![]() $\beta$ other paths through the regime diagram might be taken.

$\beta$ other paths through the regime diagram might be taken.

However, a more careful investigation reveals that there are a few additional transitional regimes, indicated by the shaded areas in the regime diagrams in figure 2. We identify these by examining the validity of some of the asymptotic assumptions made.

7. Validity of assumptions

The asymptotic results presented in this paper thus far rely on several assumptions, which we shall now check a posteriori, making use of the bending scales ![]() $x_{B}$ and

$x_{B}$ and ![]() $t_{B}$ (6.1) to keep the expressions simple.

$t_{B}$ (6.1) to keep the expressions simple.

Firstly, the governing elastic and lubrication equations (2.2) and (2.4) require the slope of the sheet to be small, ![]() $h'\ll 1$, in order to be valid. Thus, the validity of the results shown in figure 6 depends on the aspect ratio

$h'\ll 1$, in order to be valid. Thus, the validity of the results shown in figure 6 depends on the aspect ratio ![]() $x_{B}/h_0$ of the non-dimensionalization (6.1), since the true slope

$x_{B}/h_0$ of the non-dimensionalization (6.1), since the true slope ![]() $h'$ is related to the non-dimensional slope

$h'$ is related to the non-dimensional slope ![]() $h^{\prime *}$ by

$h^{\prime *}$ by ![]() $h' = (h_0/x_{B})h^{\prime *}$. In general, any non-dimensional results in a finite time range have a maximum slope

$h' = (h_0/x_{B})h^{\prime *}$. In general, any non-dimensional results in a finite time range have a maximum slope ![]() $h^{\prime *}$ and hence are valid provided that

$h^{\prime *}$ and hence are valid provided that ![]() $x_{B}/h_0 \gg h^{\prime *}$. More specific bounds can be obtained for each asymptotic regime. For example, for the two-dimensional pure-bending case (5.5a), the slope is largest in the blister, with

$x_{B}/h_0 \gg h^{\prime *}$. More specific bounds can be obtained for each asymptotic regime. For example, for the two-dimensional pure-bending case (5.5a), the slope is largest in the blister, with ![]() $h' \sim {H}/R \sim (h_0/x_{B})(t/t_{B})^{(7\beta -4)/17}$. Thus, for

$h' \sim {H}/R \sim (h_0/x_{B})(t/t_{B})^{(7\beta -4)/17}$. Thus, for ![]() $\beta < 4/7$ the slope decreases with time and the equations are valid for

$\beta < 4/7$ the slope decreases with time and the equations are valid for ![]() $t \gg t_{B}(h_0/x_{B})^{17/(4-7\beta)}$, while for

$t \gg t_{B}(h_0/x_{B})^{17/(4-7\beta)}$, while for ![]() $\beta > 4/7$ the criterion is

$\beta > 4/7$ the criterion is ![]() $t \ll t_{B}(x_{B}/h_0)^{17/(7\beta -4)}$.

$t \ll t_{B}(x_{B}/h_0)^{17/(7\beta -4)}$.

Secondly, the height ![]() ${H}(t)$ of the blister must satisfy

${H}(t)$ of the blister must satisfy ![]() ${H} \gg h_0$. Using (5.5a) as an example again, we have

${H} \gg h_0$. Using (5.5a) as an example again, we have ![]() ${H} \sim h_0(t/t_{B})^{(12\beta -2)/17}$, so for

${H} \sim h_0(t/t_{B})^{(12\beta -2)/17}$, so for ![]() $\beta > 1/6$ the result is valid at late times

$\beta > 1/6$ the result is valid at late times ![]() $t \gg t_{B}$, while for