1. Introduction

In a seminal paper, Moffatt (Reference Moffatt1964) examined two-dimensional slow viscous flow in corners bounded by plane walls, and predicted the existence of infinite sequences of viscous, non-inertial eddies under certain conditions. These eponymous ‘Moffatt eddies’ occur in wedges of half-angle, ![]() $\alpha$, less than a critical angle

$\alpha$, less than a critical angle ![]() $\alpha _c\approx 73^{\circ }$, are driven by an arbitrary (anti-symmetric) disturbance asymptotically far from the vertex of the corner, and decay exponentially in size and intensity as the vertex is approached. In this paper we examine corner eddies for viscoplastic fluids.

$\alpha _c\approx 73^{\circ }$, are driven by an arbitrary (anti-symmetric) disturbance asymptotically far from the vertex of the corner, and decay exponentially in size and intensity as the vertex is approached. In this paper we examine corner eddies for viscoplastic fluids.

A viscoplastic fluid is a type of non-Newtonian fluid, which acts as a rigid solid at stresses below a certain yield stress, ![]() $\tau _Y$, but flows like a fluid at stresses above this threshold. Many pastes and suspensions exhibit a yield stress, and so viscoplastic fluids have wide ranging applications in geophysical and industrial flows (Ancey Reference Ancey2007; Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014; Frigaard, Paso & de Souza Mendes Reference Frigaard, Paso and de Souza Mendes2017). In food processing in particular, it is important to avoid dead zones in corners where unyielded viscoplastic material can spoil and infect the passing product (The European Hygienic Equipment Design Group 1993), thus emphasising that an understanding of unyielded and recirculating zones in viscoplastic corner flows is important. Eddies occur in various examples of inertial and non-inertial flows of viscoplastic fluids, including sudden expansions and/or contractions (Scott, Mirza & Vlachopoulos Reference Scott, Mirza and Vlachopoulos1988; Jay, Magnin & Piau Reference Jay, Magnin and Piau2002; Mitsoulis & Huilgol Reference Mitsoulis and Huilgol2004; Abbott et al. Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009), thermal convection (Karimfazli, Frigaard & Wachs Reference Karimfazli, Frigaard and Wachs2016), tape casting (Loest, Lipp & Mitsoulis Reference Loest, Lipp and Mitsoulis1994) and flows through non-uniform channels (Roustaei & Frigaard Reference Roustaei and Frigaard2013, Reference Roustaei and Frigaard2015; Roustaei, Gosselin & Frigaard Reference Roustaei, Gosselin and Frigaard2015). Roustaei & Frigaard (Reference Roustaei and Frigaard2013) compute viscoplastic flow in a wavy channel in the limit of vanishing Reynolds number, and observe that, for a sufficiently low Bingham number (dimensionless yield stress) and sufficiently large amplitude channel-width variations, eddies form within the expanded regions of the channel. They make the analogy with Moffatt (Reference Moffatt1964) eddies, and comment that, in a sharp cornered wedge, one could theoretically observe arbitrarily many eddies, for a sufficiently low Bingham number. In their numerical simulations they were only able to observe a single eddy in the parameter space studied, due to the rapid drop off of intensity with distance from the vertex analogously to the high decay rates in Moffatt's solutions. Abbott et al. (Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009) analyse viscoplastic flow through an abrupt contraction, and suggest, but do not carry out, a perturbation expansion of the Moffatt solution for a right-angled corner when the yield stress is small, proposing the existence of approximately circular rotating plugs at the centre of the eddies. Finally, Chupin & Palade (Reference Chupin and Palade2008) examine the flow of viscoplastic fluids in the neighbourhood of a corner and prove that, for a concave wedge (half-angle,

$\tau _Y$, but flows like a fluid at stresses above this threshold. Many pastes and suspensions exhibit a yield stress, and so viscoplastic fluids have wide ranging applications in geophysical and industrial flows (Ancey Reference Ancey2007; Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014; Frigaard, Paso & de Souza Mendes Reference Frigaard, Paso and de Souza Mendes2017). In food processing in particular, it is important to avoid dead zones in corners where unyielded viscoplastic material can spoil and infect the passing product (The European Hygienic Equipment Design Group 1993), thus emphasising that an understanding of unyielded and recirculating zones in viscoplastic corner flows is important. Eddies occur in various examples of inertial and non-inertial flows of viscoplastic fluids, including sudden expansions and/or contractions (Scott, Mirza & Vlachopoulos Reference Scott, Mirza and Vlachopoulos1988; Jay, Magnin & Piau Reference Jay, Magnin and Piau2002; Mitsoulis & Huilgol Reference Mitsoulis and Huilgol2004; Abbott et al. Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009), thermal convection (Karimfazli, Frigaard & Wachs Reference Karimfazli, Frigaard and Wachs2016), tape casting (Loest, Lipp & Mitsoulis Reference Loest, Lipp and Mitsoulis1994) and flows through non-uniform channels (Roustaei & Frigaard Reference Roustaei and Frigaard2013, Reference Roustaei and Frigaard2015; Roustaei, Gosselin & Frigaard Reference Roustaei, Gosselin and Frigaard2015). Roustaei & Frigaard (Reference Roustaei and Frigaard2013) compute viscoplastic flow in a wavy channel in the limit of vanishing Reynolds number, and observe that, for a sufficiently low Bingham number (dimensionless yield stress) and sufficiently large amplitude channel-width variations, eddies form within the expanded regions of the channel. They make the analogy with Moffatt (Reference Moffatt1964) eddies, and comment that, in a sharp cornered wedge, one could theoretically observe arbitrarily many eddies, for a sufficiently low Bingham number. In their numerical simulations they were only able to observe a single eddy in the parameter space studied, due to the rapid drop off of intensity with distance from the vertex analogously to the high decay rates in Moffatt's solutions. Abbott et al. (Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009) analyse viscoplastic flow through an abrupt contraction, and suggest, but do not carry out, a perturbation expansion of the Moffatt solution for a right-angled corner when the yield stress is small, proposing the existence of approximately circular rotating plugs at the centre of the eddies. Finally, Chupin & Palade (Reference Chupin and Palade2008) examine the flow of viscoplastic fluids in the neighbourhood of a corner and prove that, for a concave wedge (half-angle, ![]() $\alpha <{\rm \pi} /2$), the fluid must be unyielded in some neighbourhood of the vertex, the scale of which they do not determine. As noted above, the extent of this unyielded stagnant region is important for applications in which the aim is to mix or dislodge a viscoplastic fluid, as it corresponds to material undisturbed by the forcing.

$\alpha <{\rm \pi} /2$), the fluid must be unyielded in some neighbourhood of the vertex, the scale of which they do not determine. As noted above, the extent of this unyielded stagnant region is important for applications in which the aim is to mix or dislodge a viscoplastic fluid, as it corresponds to material undisturbed by the forcing.

In the current work we present a detailed numerical and analytical study of viscoplastic corner eddies, describing and rationalising the critical Bingham numbers at which new eddies form for wedges of different half-angle. We first consider an idealised case where it is assumed that the dominant solution of Moffatt (Reference Moffatt1964) is fully developed at large radial distances from the vertex, and we then consider the behaviour at smaller distances, where viscoplasticity first becomes significant. We define this problem in § 2 and describe the numerical methods in § 3, before reporting and rationalising the results in § 4. In § 5 we compare this idealised case, forced by the dominant Moffatt solution, with a particular example of flow past a triangular inclusion, driven by a translating lid, to illustrate the relevance of the idealised theory to practical situations in which these eddies occur. Finally, we conclude in § 6. There are also two appendices in which we explore the derivation of the critical Bingham number in greater detail, and demonstrate that viscoplastic eddies in rectangular channels can also be described by our work by considering the limit ![]() $\alpha \to 0$.

$\alpha \to 0$.

2. Problem definition

Throughout the following we assume slow, non-inertial flow of a Bingham fluid, defined by the constitutive law, ![]() $\boldsymbol {\tau }=(\mu +\tau _Y/\|\dot {\boldsymbol {\gamma }}\|) \dot {\boldsymbol {\gamma }} \text { when } \|\boldsymbol {\tau }\|>\tau _Y$, and

$\boldsymbol {\tau }=(\mu +\tau _Y/\|\dot {\boldsymbol {\gamma }}\|) \dot {\boldsymbol {\gamma }} \text { when } \|\boldsymbol {\tau }\|>\tau _Y$, and ![]() $\dot {\boldsymbol {\gamma }}=\boldsymbol {0}$ otherwise, relating the deviatoric stress tensor,

$\dot {\boldsymbol {\gamma }}=\boldsymbol {0}$ otherwise, relating the deviatoric stress tensor, ![]() $\boldsymbol {\tau }$, to the strain-rate tensor,

$\boldsymbol {\tau }$, to the strain-rate tensor, ![]() $\dot {\boldsymbol {\gamma }}=(\boldsymbol {\nabla } \boldsymbol {u})+(\boldsymbol {\nabla }\boldsymbol {u})^{\rm T}$, and their second invariants,

$\dot {\boldsymbol {\gamma }}=(\boldsymbol {\nabla } \boldsymbol {u})+(\boldsymbol {\nabla }\boldsymbol {u})^{\rm T}$, and their second invariants, ![]() $\|\boldsymbol {\tau }\|$ and

$\|\boldsymbol {\tau }\|$ and ![]() $\|\dot {\boldsymbol {\gamma }}\|$, where the second invariant of a tensor,

$\|\dot {\boldsymbol {\gamma }}\|$, where the second invariant of a tensor, ![]() $\boldsymbol{\mathsf{T}}$, is defined by

$\boldsymbol{\mathsf{T}}$, is defined by ![]() $\|\boldsymbol{\mathsf{T}}\|=\sqrt {{\mathsf{T}}_{ij}{\mathsf{T}}_{ij}/2}$. The parameters

$\|\boldsymbol{\mathsf{T}}\|=\sqrt {{\mathsf{T}}_{ij}{\mathsf{T}}_{ij}/2}$. The parameters ![]() $\mu$ and

$\mu$ and ![]() $\tau _Y$ are the viscosity and yield stress, respectively. We consider two-dimensional motion within an infinite planar wedge of half-angle

$\tau _Y$ are the viscosity and yield stress, respectively. We consider two-dimensional motion within an infinite planar wedge of half-angle ![]() $\alpha$. For a viscous Newtonian fluid, the existence of Moffatt (Reference Moffatt1964) eddies is derived by searching for anti-symmetric solutions for the streamfunction,

$\alpha$. For a viscous Newtonian fluid, the existence of Moffatt (Reference Moffatt1964) eddies is derived by searching for anti-symmetric solutions for the streamfunction, ![]() $\psi _V$, satisfying the biharmonic equation,

$\psi _V$, satisfying the biharmonic equation,

and no-slip on the planar boundaries ![]() $\theta =\pm \alpha$. In plane polar coordinates

$\theta =\pm \alpha$. In plane polar coordinates ![]() $(r,\theta )$, centred on the vertex of the wedge, making the ansatz of a separable solution, one finds a discrete set of solutions, given by the real part of

$(r,\theta )$, centred on the vertex of the wedge, making the ansatz of a separable solution, one finds a discrete set of solutions, given by the real part of

where

the eigenvalue, ![]() $\lambda =\lambda _r+\textrm {i}\lambda _i$, is a solution of

$\lambda =\lambda _r+\textrm {i}\lambda _i$, is a solution of

and ![]() $A$ is a general (complex) constant. We will consider the dominant solution in the vicinity of the corner, given by the eigenvalue with the smallest real part. For all values of

$A$ is a general (complex) constant. We will consider the dominant solution in the vicinity of the corner, given by the eigenvalue with the smallest real part. For all values of ![]() $\alpha$ below the critical value,

$\alpha$ below the critical value, ![]() $\alpha _c\approx 73^{\circ }$,

$\alpha _c\approx 73^{\circ }$, ![]() $\lambda$ is complex, giving rise to the oscillatory behaviour interpreted as eddies. Consecutive eddies are geometrically similar, with a length scale factor of

$\lambda$ is complex, giving rise to the oscillatory behaviour interpreted as eddies. Consecutive eddies are geometrically similar, with a length scale factor of ![]() $S_0\equiv \exp ({-{\rm \pi} /\lambda _i})$ and corresponding velocity and strain-rate/vorticity factors of

$S_0\equiv \exp ({-{\rm \pi} /\lambda _i})$ and corresponding velocity and strain-rate/vorticity factors of ![]() $S_1\equiv \exp ({-(\lambda _r-1){\rm \pi} /\lambda _i})$ and

$S_1\equiv \exp ({-(\lambda _r-1){\rm \pi} /\lambda _i})$ and ![]() $S_2\equiv \exp ({-(\lambda _r-2){\rm \pi} /\lambda _i})$, respectively. This last factor is of particular importance when considering viscoplastic fluids, since the magnitude of the strain rate determines the significance of the yield stress term relative to the viscous term in the constitutive law. For all

$S_2\equiv \exp ({-(\lambda _r-2){\rm \pi} /\lambda _i})$, respectively. This last factor is of particular importance when considering viscoplastic fluids, since the magnitude of the strain rate determines the significance of the yield stress term relative to the viscous term in the constitutive law. For all ![]() $\alpha <\alpha _c$, we have

$\alpha <\alpha _c$, we have ![]() $\lambda _r>2$, and a decaying strain rate as

$\lambda _r>2$, and a decaying strain rate as ![]() $r\to 0$, underpinning why fluid in the apex of the corner is unyielded. The value of the factor

$r\to 0$, underpinning why fluid in the apex of the corner is unyielded. The value of the factor ![]() $S_2$ is plotted against

$S_2$ is plotted against ![]() $\alpha$ in figure 1 showing that it vanishes as

$\alpha$ in figure 1 showing that it vanishes as ![]() $\alpha \to \alpha _c$, and attains a maximum of

$\alpha \to \alpha _c$, and attains a maximum of ![]() $0.0078$ for

$0.0078$ for ![]() $\alpha =40^{\circ }$ (both given to

$\alpha =40^{\circ }$ (both given to ![]() $2$ significant figures).

$2$ significant figures).

Figure 1. Strain-rate factor, ![]() $S_2=\exp ({-(\lambda _r-2){\rm \pi} /\lambda _i})$, as a function of corner half-angle,

$S_2=\exp ({-(\lambda _r-2){\rm \pi} /\lambda _i})$, as a function of corner half-angle, ![]() $\alpha$.

$\alpha$.

Since the strain rate increases with ![]() $r$, there exists a viscoplastic flow in the same domain, which asymptotically tends to this viscous solution at sufficiently large distances from the vertex. The fluid will be static and unyielded at small distances, and the eddies will be essentially unchanged at large distances. There are a few locations in the viscous solutions at which the strain rate vanishes, around which we would expect regions of unyielded fluid for a viscoplastic fluid. These include: points on the

$r$, there exists a viscoplastic flow in the same domain, which asymptotically tends to this viscous solution at sufficiently large distances from the vertex. The fluid will be static and unyielded at small distances, and the eddies will be essentially unchanged at large distances. There are a few locations in the viscous solutions at which the strain rate vanishes, around which we would expect regions of unyielded fluid for a viscoplastic fluid. These include: points on the ![]() $\theta =0$ plane near the centre of each eddy; pairs of points on the upper and lower boundaries at the stagnation points between consecutive eddies; and, less intuitively, pairs of points a small distance vertically above and below the points on the

$\theta =0$ plane near the centre of each eddy; pairs of points on the upper and lower boundaries at the stagnation points between consecutive eddies; and, less intuitively, pairs of points a small distance vertically above and below the points on the ![]() $\theta =0$ plane. However, since the ratio of strain rates between two consecutive Moffatt eddies is never greater than 0.008 for any

$\theta =0$ plane. However, since the ratio of strain rates between two consecutive Moffatt eddies is never greater than 0.008 for any ![]() $\alpha$ (see figure 1), for a given yield stress and viscosity, there will never be two consecutive eddies in which the yield stress plays a leading-order role. More precisely, the material parameters define a strain-rate scale

$\alpha$ (see figure 1), for a given yield stress and viscosity, there will never be two consecutive eddies in which the yield stress plays a leading-order role. More precisely, the material parameters define a strain-rate scale ![]() $\tau _Y/\mu$, while each of the viscous Moffatt (Reference Moffatt1964) eddies has a typical strain rate. If we label the Moffatt eddies via the index

$\tau _Y/\mu$, while each of the viscous Moffatt (Reference Moffatt1964) eddies has a typical strain rate. If we label the Moffatt eddies via the index ![]() $k\in \mathbb {Z}$, with

$k\in \mathbb {Z}$, with ![]() $k\to -\infty$ corresponding to the tip of the corner, and define the strain-rate scale of the

$k\to -\infty$ corresponding to the tip of the corner, and define the strain-rate scale of the ![]() $k$th eddy as

$k$th eddy as ![]() $\varGamma _k=U_k/L_k$, where the dividing streamline between the

$\varGamma _k=U_k/L_k$, where the dividing streamline between the ![]() $k$th and

$k$th and ![]() $(k+1)$th eddy passes through

$(k+1)$th eddy passes through ![]() $(L_k,0)$ with velocity

$(L_k,0)$ with velocity ![]() $U_k$, then we can define a local Bingham number for each eddy via the ratio of these two strain-rate scales,

$U_k$, then we can define a local Bingham number for each eddy via the ratio of these two strain-rate scales, ![]() $\textit {Bi}_k=\tau _Y/(\mu \varGamma _k)$. By the self-similarity of the Moffatt (Reference Moffatt1964) solution, we can write all

$\textit {Bi}_k=\tau _Y/(\mu \varGamma _k)$. By the self-similarity of the Moffatt (Reference Moffatt1964) solution, we can write all ![]() $\varGamma _k$ in terms of a reference eddy,

$\varGamma _k$ in terms of a reference eddy, ![]() $k=0$, via

$k=0$, via ![]() $\varGamma _k=S_2^{-k}\varGamma _0=S_2^{-k}U_0/L_0$, where

$\varGamma _k=S_2^{-k}\varGamma _0=S_2^{-k}U_0/L_0$, where ![]() $S_2$ is the strain-rate factor defined above, and, hence,

$S_2$ is the strain-rate factor defined above, and, hence, ![]() $\textit {Bi}_k=S_2\,^{k}\textit {Bi}_0$. Since

$\textit {Bi}_k=S_2\,^{k}\textit {Bi}_0$. Since ![]() $S_2<0.008$, only a single eddy can have an

$S_2<0.008$, only a single eddy can have an ![]() $O(1)$ Bingham number (with the Bingham number being a factor of over 100 smaller/larger in the eddy further from/nearer to the vertex). In other words, for the viscoplastic fluid, we expect that all but one of the eddies from the purely viscous solution will be unyielded and static, or else unchanged to leading order, with the unyielded regions around points of vanishing strain rate being negligibly small. Without loss of generality, we can choose

$O(1)$ Bingham number (with the Bingham number being a factor of over 100 smaller/larger in the eddy further from/nearer to the vertex). In other words, for the viscoplastic fluid, we expect that all but one of the eddies from the purely viscous solution will be unyielded and static, or else unchanged to leading order, with the unyielded regions around points of vanishing strain rate being negligibly small. Without loss of generality, we can choose ![]() $k=0$ to correspond to this unique eddy, and non-dimensionalise lengths by

$k=0$ to correspond to this unique eddy, and non-dimensionalise lengths by ![]() $L_0$ and velocities by

$L_0$ and velocities by ![]() $U_0$. With this choice, in non-dimensional variables, the dividing streamline between the

$U_0$. With this choice, in non-dimensional variables, the dividing streamline between the ![]() $0$th and

$0$th and ![]() $1$st eddy passes through

$1$st eddy passes through ![]() $(r=1, \theta =0)$ with unit velocity in the

$(r=1, \theta =0)$ with unit velocity in the ![]() $\theta$-direction (see figure 2). This fixes the constant

$\theta$-direction (see figure 2). This fixes the constant ![]() $A$ in (2.2), and the streamfunction at large distances is given, to leading order, by

$A$ in (2.2), and the streamfunction at large distances is given, to leading order, by

where ![]() $f(\theta )$ is given by (2.3) and the real part is assumed. We further non-dimensionalise stresses and pressure by the typical viscous stress,

$f(\theta )$ is given by (2.3) and the real part is assumed. We further non-dimensionalise stresses and pressure by the typical viscous stress, ![]() $\mu \varGamma _0=\mu U_0/L_0$, giving the global Bingham number,

$\mu \varGamma _0=\mu U_0/L_0$, giving the global Bingham number,

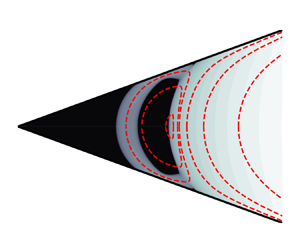

Figure 2. Schematic of viscoplastic eddies in a wedge. Black regions represent unyielded fluid, and only half of the domain is shown, with the lower half determined by anti-symmetry under vertical reflection. No eddies are present in region (a), where the fluid is unyielded, and the eddies in region (b) are essentially unchanged from the corresponding viscous eddies described by Moffatt (Reference Moffatt1964).

In the following numerical simulations we will sometimes take a value of ![]() $\textit {Bi}\ll 1$, at which new eddies open up below the one at

$\textit {Bi}\ll 1$, at which new eddies open up below the one at ![]() $r=1$. These cases are included to demonstrate the self-similarity between two consecutive generations of eddies, and to explore the critical point at which a new eddy is formed; however, we point out that when the problem is scaled as detailed above, then these Bingham numbers are technically inadmissable. Formally, due to the infinite, self-similar domain and the self-similar nature of the Moffatt solution being applied as a boundary condition, these cases should be considered as identical to rescaled problems in which the lengths are divided by

$r=1$. These cases are included to demonstrate the self-similarity between two consecutive generations of eddies, and to explore the critical point at which a new eddy is formed; however, we point out that when the problem is scaled as detailed above, then these Bingham numbers are technically inadmissable. Formally, due to the infinite, self-similar domain and the self-similar nature of the Moffatt solution being applied as a boundary condition, these cases should be considered as identical to rescaled problems in which the lengths are divided by ![]() $S_0$, velocities by

$S_0$, velocities by ![]() $S_1$ and the Bingham number by

$S_1$ and the Bingham number by ![]() $S_2$. And, after such a rescaling, they would be consistent with the scaled problem defined above, with

$S_2$. And, after such a rescaling, they would be consistent with the scaled problem defined above, with ![]() $\textit {Bi}=O(1)$ and the smallest eddy occurring just below

$\textit {Bi}=O(1)$ and the smallest eddy occurring just below ![]() $r=1$.

$r=1$.

After non-dimensionalisation, the governing equations for velocity, ![]() $\boldsymbol {u}=(u_r,u_\theta )$, pressure,

$\boldsymbol {u}=(u_r,u_\theta )$, pressure, ![]() $p$, and deviatoric stress,

$p$, and deviatoric stress, ![]() $\boldsymbol {\tau }$, are

$\boldsymbol {\tau }$, are

representing incompressibility and the balance of momentum. The Bingham constitutive law is given in non-dimensional form by

We consider anti-symmetric solutions in the upper half of the domain, ![]() $0\leqslant \theta \leqslant \alpha$, with boundary conditions

$0\leqslant \theta \leqslant \alpha$, with boundary conditions

representing no-slip, anti-symmetry and the far-field condition, respectively.

3. Numerical method

We compute finite element numerical simulations, using the augmented-Lagrangian method (for full details see, e.g. Saramito Reference Saramito2016), over a wide range of ![]() $\textit {Bi}$ and for

$\textit {Bi}$ and for ![]() $\alpha =5^{\circ }, 20^{\circ }, 45^{\circ }$ and

$\alpha =5^{\circ }, 20^{\circ }, 45^{\circ }$ and ![]() $60^{\circ }$ (as well as

$60^{\circ }$ (as well as ![]() $\alpha =0^{\circ }$ in Appendix B). This algorithm circumvents the singular nature of the constitutive law at the yield surfaces via the introduction of an independent tensorial field,

$\alpha =0^{\circ }$ in Appendix B). This algorithm circumvents the singular nature of the constitutive law at the yield surfaces via the introduction of an independent tensorial field, ![]() $\boldsymbol{\mathsf{D}}$, representing the strain-rate tensor, and a Lagrangian multiplier, standing for the deviatoric stress tensor, which enforces the equivalence of

$\boldsymbol{\mathsf{D}}$, representing the strain-rate tensor, and a Lagrangian multiplier, standing for the deviatoric stress tensor, which enforces the equivalence of ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\dot {\boldsymbol {\gamma }}(\boldsymbol {u})$. In contrast to regularisation methods, in which unyielded regions are replaced with regions of very high viscosity, the augmented-Lagrangian method accurately represents solid regions by setting

$\dot {\boldsymbol {\gamma }}(\boldsymbol {u})$. In contrast to regularisation methods, in which unyielded regions are replaced with regions of very high viscosity, the augmented-Lagrangian method accurately represents solid regions by setting ![]() $\boldsymbol{\mathsf{D}}=\boldsymbol {0}$ for stresses below the yield stress. We implement the numerical method in FEniCS, a numerical implementation of the finite element method (Logg, Mardal & Wells Reference Logg, Mardal and Wells2012; Alnæs et al. Reference Alnæs, Blechta, Hake, Johansson, Kehlet, Logg, Richardson, Ring, Rognes and Wells2015) and employ a simple adaptive mesh refinement algorithm where periodically in the augmented-Lagrangian iterations (typically every 50 iterations) we refine cells in the vicinity of the yield surface. Specifically, we refine cells for which the deviatoric stress variable lies within some tolerance of

$\boldsymbol{\mathsf{D}}=\boldsymbol {0}$ for stresses below the yield stress. We implement the numerical method in FEniCS, a numerical implementation of the finite element method (Logg, Mardal & Wells Reference Logg, Mardal and Wells2012; Alnæs et al. Reference Alnæs, Blechta, Hake, Johansson, Kehlet, Logg, Richardson, Ring, Rognes and Wells2015) and employ a simple adaptive mesh refinement algorithm where periodically in the augmented-Lagrangian iterations (typically every 50 iterations) we refine cells in the vicinity of the yield surface. Specifically, we refine cells for which the deviatoric stress variable lies within some tolerance of ![]() $Bi$. For the first refinement, we use a tolerance

$Bi$. For the first refinement, we use a tolerance ![]() $Bi/2$, and decrease the tolerance by

$Bi/2$, and decrease the tolerance by ![]() $25\,\%$ for each subsequent refinement to encompass consistently the yield surface while somewhat limiting the number of new cells produced. We stop refining after five refinement steps, or once the new mesh size would be above some chosen limit – in this case, 280 000 cells. In place of the far-field boundary condition, (2.12), we truncate the domain at the straight boundary

$25\,\%$ for each subsequent refinement to encompass consistently the yield surface while somewhat limiting the number of new cells produced. We stop refining after five refinement steps, or once the new mesh size would be above some chosen limit – in this case, 280 000 cells. In place of the far-field boundary condition, (2.12), we truncate the domain at the straight boundary ![]() $x=r\cos \theta =x_R$ and impose the viscous Moffatt (Reference Moffatt1964) solution

$x=r\cos \theta =x_R$ and impose the viscous Moffatt (Reference Moffatt1964) solution

on this boundary. When choosing the truncation position, ![]() $x_R$, we require that the strain rate is significantly larger than

$x_R$, we require that the strain rate is significantly larger than ![]() $\textit {Bi}$ along

$\textit {Bi}$ along ![]() $x=x_R$, so that the viscous solution is a good approximation to the viscoplastic solution at the truncated boundary and, hence, that the solution is essentially unchanged by the truncation of the domain. In particular this requires avoiding any of the points at which the strain rate vanishes in the Moffatt (Reference Moffatt1964) solution. To check the impact of truncation at

$x=x_R$, so that the viscous solution is a good approximation to the viscoplastic solution at the truncated boundary and, hence, that the solution is essentially unchanged by the truncation of the domain. In particular this requires avoiding any of the points at which the strain rate vanishes in the Moffatt (Reference Moffatt1964) solution. To check the impact of truncation at ![]() $x=x_R$, simulations were repeated on domains at least

$x=x_R$, simulations were repeated on domains at least ![]() $50\,\%$ larger and the velocity solution and inner plug depths,

$50\,\%$ larger and the velocity solution and inner plug depths, ![]() $d$, were found to differ by less than

$d$, were found to differ by less than ![]() $1\,\%$ for all solutions. The values of

$1\,\%$ for all solutions. The values of ![]() $x_R$ varied between

$x_R$ varied between ![]() $1.5$ and

$1.5$ and ![]() $15$ for the different values of

$15$ for the different values of ![]() $\textit {Bi}$ and

$\textit {Bi}$ and ![]() $\alpha$, with the largest domain being needed for the simulation with

$\alpha$, with the largest domain being needed for the simulation with ![]() $\alpha =60$ and

$\alpha =60$ and ![]() $\textit {Bi}=2$. All simulations converged to a residual,

$\textit {Bi}=2$. All simulations converged to a residual, ![]() $\|\sqrt {({\mathsf{D}}_{ij}-\dot {\gamma }_{ij})({\mathsf{D}}_{ij}-\dot {\gamma }_{ij})}\|_{L^{2}}$, of less than

$\|\sqrt {({\mathsf{D}}_{ij}-\dot {\gamma }_{ij})({\mathsf{D}}_{ij}-\dot {\gamma }_{ij})}\|_{L^{2}}$, of less than ![]() $10^{-5}$, with many of the smaller Bingham number simulations converging to significantly lower residuals.

$10^{-5}$, with many of the smaller Bingham number simulations converging to significantly lower residuals.

4. Results and key scalings

A typical set of numerical solutions is given in figure 3 demonstrating the existence of three unyielded regions, as observed in Roustaei & Frigaard (Reference Roustaei and Frigaard2013): a static unyielded region in the corner of the wedge; a small static unyielded region on the boundary at the stagnation point between eddies; and a plug region in solid-body motion within the eddy. All regions decrease in size as ![]() $\textit {Bi}$ decreases, until a new eddy forms at sufficiently small

$\textit {Bi}$ decreases, until a new eddy forms at sufficiently small ![]() $\textit {Bi}$. While Abbott et al. (Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009) predicted an approximately circular plug rotating at the ‘centre’ of the eddy, we note that this plug is somewhat unintuitive, not encompassing the centre of the eddy and, as a result, being closer to a semi-circle in shape. This is due to the fact that in Moffatt eddies, the point on the wedge's symmetry axis at which the strain rate vanishes is distinct from the point where the velocity vanishes. Furthermore, though this plug is undergoing solid-body rotation, there is no requirement that its boundary is circular, since the yield surface need not be a material surface (streamlines can exit and enter the plug as the fluid element yields and unyields). We see that the flow in the eddy in

$\textit {Bi}$. While Abbott et al. (Reference Abbott, Braun, Breward, Cook, Cromer, Edwards, Hibdon, Please, Taroni and Zhang2009) predicted an approximately circular plug rotating at the ‘centre’ of the eddy, we note that this plug is somewhat unintuitive, not encompassing the centre of the eddy and, as a result, being closer to a semi-circle in shape. This is due to the fact that in Moffatt eddies, the point on the wedge's symmetry axis at which the strain rate vanishes is distinct from the point where the velocity vanishes. Furthermore, though this plug is undergoing solid-body rotation, there is no requirement that its boundary is circular, since the yield surface need not be a material surface (streamlines can exit and enter the plug as the fluid element yields and unyields). We see that the flow in the eddy in ![]() $r>1$ is largely unchanged for these Bingham numbers, although the streamlines are slightly altered at the inner extent of the eddy for larger

$r>1$ is largely unchanged for these Bingham numbers, although the streamlines are slightly altered at the inner extent of the eddy for larger ![]() $\textit {Bi}$, and that once a new eddy has formed, the unyielded regions in the eddy above have become negligibly small, as anticipated. Note also that, as discussed in § 2, the solution in panel (d) is equivalent to a rescaled problem where the first eddy has its rightmost extent at

$\textit {Bi}$, and that once a new eddy has formed, the unyielded regions in the eddy above have become negligibly small, as anticipated. Note also that, as discussed in § 2, the solution in panel (d) is equivalent to a rescaled problem where the first eddy has its rightmost extent at ![]() $r=1$ and

$r=1$ and ![]() $Bi$ is multiplied by

$Bi$ is multiplied by ![]() $S_2^{-1}=\exp ({(\lambda _r-2){\rm \pi} /\lambda _i})\approx 170$. This gives

$S_2^{-1}=\exp ({(\lambda _r-2){\rm \pi} /\lambda _i})\approx 170$. This gives ![]() $Bi=3.0$ (to

$Bi=3.0$ (to ![]() $2$ significant figures), and so we expect panels

$2$ significant figures), and so we expect panels ![]() $(a)$ and

$(a)$ and ![]() $(d)$ to be equivalent up to scaling, as is observed.

$(d)$ to be equivalent up to scaling, as is observed.

Figure 3. Contours of the modulus of the strain rate, ![]() $\|\dot {\boldsymbol {\gamma }}\|$, (grey scale) and streamlines (red) for

$\|\dot {\boldsymbol {\gamma }}\|$, (grey scale) and streamlines (red) for ![]() $\alpha =20^{\circ }$ and (a)

$\alpha =20^{\circ }$ and (a) ![]() $Bi=3$, (b)

$Bi=3$, (b) ![]() $Bi=1$, (c)

$Bi=1$, (c) ![]() $Bi=0.25$ and (d)

$Bi=0.25$ and (d) ![]() $Bi=0.018$. The unyielded regions are shown in black. The critical Bingham number at which a new eddy forms,

$Bi=0.018$. The unyielded regions are shown in black. The critical Bingham number at which a new eddy forms, ![]() $\textit {Bi}_c$, lies somewhere between the value of

$\textit {Bi}_c$, lies somewhere between the value of ![]() $\textit {Bi}$ for panels (c) and (d). Note the logarithmic scale for the strain rate.

$\textit {Bi}$ for panels (c) and (d). Note the logarithmic scale for the strain rate.

Two key features of the problem are the extent of the stagnant unyielded plug in the corner as a function of ![]() $Bi$, and the critical Bingham numbers,

$Bi$, and the critical Bingham numbers, ![]() $Bi_c$, at which a new eddy forms. We measure the former as the distance,

$Bi_c$, at which a new eddy forms. We measure the former as the distance, ![]() $d$, of the yield surface from the vertex of the wedge, along the

$d$, of the yield surface from the vertex of the wedge, along the ![]() $\theta =0$ plane. The stars in figure 4 show

$\theta =0$ plane. The stars in figure 4 show ![]() $d$ against

$d$ against ![]() $Bi$ for four values of

$Bi$ for four values of ![]() $\alpha$, determined from the numerical simulations. The first plot shows how

$\alpha$, determined from the numerical simulations. The first plot shows how ![]() $d$ decreases with

$d$ decreases with ![]() $Bi$ after the creation of the second eddy and before the creation of a third, while the log–log plots demonstrate the existence and location of the critical Bingham numbers at which the value of

$Bi$ after the creation of the second eddy and before the creation of a third, while the log–log plots demonstrate the existence and location of the critical Bingham numbers at which the value of ![]() $d$ jumps due to the formation/disappearance of an eddy, and the equivalence up to scaling of consecutive eddies evidenced by the translational periodicity of the curves. In the following section we provide a heuristic argument for approximating

$d$ jumps due to the formation/disappearance of an eddy, and the equivalence up to scaling of consecutive eddies evidenced by the translational periodicity of the curves. In the following section we provide a heuristic argument for approximating ![]() $Bi_c$ and the values of

$Bi_c$ and the values of ![]() $d$ before and after a new eddy forms.

$d$ before and after a new eddy forms.

Figure 4. Extent of the static plug in the corner of the wedge, ![]() $d$, as a function of

$d$, as a function of ![]() $Bi$. Symbols show numerical results while the dotted lines show our heuristic predictions. (a) Plots of

$Bi$. Symbols show numerical results while the dotted lines show our heuristic predictions. (a) Plots of ![]() $\alpha =20^{\circ }$ on a linear-linear scale, showing variation of

$\alpha =20^{\circ }$ on a linear-linear scale, showing variation of ![]() $d$ with

$d$ with ![]() $Bi$. Log–log plots across a larger range of

$Bi$. Log–log plots across a larger range of ![]() $Bi$ are given for (b)

$Bi$ are given for (b) ![]() $\alpha =5^{\circ }$, (c)

$\alpha =5^{\circ }$, (c) ![]() $\alpha =20^{\circ }$, (d)

$\alpha =20^{\circ }$, (d) ![]() $\alpha =45^{\circ }$ and (e)

$\alpha =45^{\circ }$ and (e) ![]() $\alpha =60^{\circ }$, showing the jumps at critical values of

$\alpha =60^{\circ }$, showing the jumps at critical values of ![]() $Bi$ where a new eddy forms and the self-similarity of consecutive generations of eddies. The red points

$Bi$ where a new eddy forms and the self-similarity of consecutive generations of eddies. The red points ![]() $A$,

$A$, ![]() $B$,

$B$, ![]() $C$ and

$C$ and ![]() $D$ in panel (c) indicate the four points derived in the heuristic approximation, as detailed in § 4.1.

$D$ in panel (c) indicate the four points derived in the heuristic approximation, as detailed in § 4.1.

4.1. The critical Bingham number

A heuristic argument to approximate the critical Bingham number, ![]() $Bi_c$, for a given half-angle,

$Bi_c$, for a given half-angle, ![]() $\alpha$, is as follows. We observe that the eddy adjacent to a newly opened eddy fully contains the corresponding viscous Moffatt (Reference Moffatt1964) eddy and consider a semi-circle, meeting the boundary tangentially, with diameter centred on

$\alpha$, is as follows. We observe that the eddy adjacent to a newly opened eddy fully contains the corresponding viscous Moffatt (Reference Moffatt1964) eddy and consider a semi-circle, meeting the boundary tangentially, with diameter centred on ![]() $(x_0,0)$, where

$(x_0,0)$, where ![]() $x_0$ is the smallest

$x_0$ is the smallest ![]() $x$-coordinate attained by this Moffatt eddy (see figure 5). Note that

$x$-coordinate attained by this Moffatt eddy (see figure 5). Note that ![]() $x_0$ is known a priori, since the Moffatt solution is known analytically, but is only a heuristic approximation to the minimum distance attained by the viscoplastic eddy. Appendix A outlines a more rigorous approach to determine the region of the static corner plug that yields to rotation as the Bingham number is reduced; however, for the purposes of a heuristic argument, we appeal to the observation from numerical simulations that this semi-circle is a good approximation to the true yield surface, as seen in figure 5. The normal stresses acting on the diameter of the semi-circle exert a dimensionless torque, denoted by

$x_0$ is known a priori, since the Moffatt solution is known analytically, but is only a heuristic approximation to the minimum distance attained by the viscoplastic eddy. Appendix A outlines a more rigorous approach to determine the region of the static corner plug that yields to rotation as the Bingham number is reduced; however, for the purposes of a heuristic argument, we appeal to the observation from numerical simulations that this semi-circle is a good approximation to the true yield surface, as seen in figure 5. The normal stresses acting on the diameter of the semi-circle exert a dimensionless torque, denoted by ![]() $2G$, around

$2G$, around ![]() $(x_0,0)$ on the fluid contained in the semi-circle, which must be balanced by the torque due to the tangential stresses along the circumference of the semi-circle (since, in the absence of inertia, torques must balance). The dimensionless torque,

$(x_0,0)$ on the fluid contained in the semi-circle, which must be balanced by the torque due to the tangential stresses along the circumference of the semi-circle (since, in the absence of inertia, torques must balance). The dimensionless torque, ![]() $G$, is given by

$G$, is given by

\begin{equation} G=\left\lvert\int_0^{R} y\left({-}p+\tau_{xx}\right){{\rm d}y}\right\rvert,\end{equation}

\begin{equation} G=\left\lvert\int_0^{R} y\left({-}p+\tau_{xx}\right){{\rm d}y}\right\rvert,\end{equation}

where ![]() $R=x_0\sin \alpha$ is the radius of the semi-circle, and the integral is calculated along

$R=x_0\sin \alpha$ is the radius of the semi-circle, and the integral is calculated along ![]() $x=x_0$. While the fluid is unyielded along the circular arc, the maximum possible torque per unit length is

$x=x_0$. While the fluid is unyielded along the circular arc, the maximum possible torque per unit length is ![]() $R\textit {Bi}$. In practice, the semi-circle may extend slightly beyond the yield surface (see figure 5) which would slightly alter the torque along the arc in this region but nonetheless the maximum torque along the circumference in the upper half of the wedge is approximately

$R\textit {Bi}$. In practice, the semi-circle may extend slightly beyond the yield surface (see figure 5) which would slightly alter the torque along the arc in this region but nonetheless the maximum torque along the circumference in the upper half of the wedge is approximately ![]() ${\rm \pi} R^{2}\textit {Bi}/2$. At the critical Bingham number,

${\rm \pi} R^{2}\textit {Bi}/2$. At the critical Bingham number, ![]() $\textit {Bi}_c$, we hence have

$\textit {Bi}_c$, we hence have

The final approximation we make is to use the purely viscous solution for ![]() $p$ and

$p$ and ![]() $\tau _{xx}$, encoded by the streamfunction

$\tau _{xx}$, encoded by the streamfunction ![]() $\psi _V$, (2.5), in (4.1), when evaluating

$\psi _V$, (2.5), in (4.1), when evaluating ![]() $G$ in (4.2). This allows us to calculate an approximation for

$G$ in (4.2). This allows us to calculate an approximation for ![]() $\textit {Bi}_c$ for any

$\textit {Bi}_c$ for any ![]() $\alpha$, purely from the Moffatt solution given by (2.5). Figure 6(a) shows the value of

$\alpha$, purely from the Moffatt solution given by (2.5). Figure 6(a) shows the value of ![]() $G$ calculated using the Moffatt solution, while the stars are from the numerical simulations shown in figure 5(a–d). The close correspondence of these curves demonstrates the validity of the approximation. Figure 6(b) shows the predicted value of

$G$ calculated using the Moffatt solution, while the stars are from the numerical simulations shown in figure 5(a–d). The close correspondence of these curves demonstrates the validity of the approximation. Figure 6(b) shows the predicted value of ![]() $\textit {Bi}_c$ as a function of

$\textit {Bi}_c$ as a function of ![]() $\alpha$, alongside the smallest Bingham numbers of numerical simulations at which the new eddy had not yet formed (representing a numerical upper bound for

$\alpha$, alongside the smallest Bingham numbers of numerical simulations at which the new eddy had not yet formed (representing a numerical upper bound for ![]() $\textit {Bi}_c$). Interestingly, the predicted value of

$\textit {Bi}_c$). Interestingly, the predicted value of ![]() $\textit {Bi}_c$ is approximately constant over a wide range of angles,

$\textit {Bi}_c$ is approximately constant over a wide range of angles, ![]() $15^{\circ }\lessapprox \alpha \lessapprox 45^{\circ }$, diverging like

$15^{\circ }\lessapprox \alpha \lessapprox 45^{\circ }$, diverging like ![]() $1/\alpha$ as

$1/\alpha$ as ![]() $\alpha \to 0$ and tending to

$\alpha \to 0$ and tending to ![]() $0$ as

$0$ as ![]() $\alpha \to \alpha _c$. The latter is anticipated since the relative intensity of consecutive eddies vanishes in this limit requiring a vanishing Bingham number to exhibit additional eddies. The divergent behaviour as

$\alpha \to \alpha _c$. The latter is anticipated since the relative intensity of consecutive eddies vanishes in this limit requiring a vanishing Bingham number to exhibit additional eddies. The divergent behaviour as ![]() $\alpha \to 0$ can also be understood, by instead considering

$\alpha \to 0$ can also be understood, by instead considering ![]() $\alpha \to 0$ with

$\alpha \to 0$ with ![]() $r\alpha =1$ fixed, which is the typical way to treat this limit and which represents convergence to a uniform channel of width 2, for

$r\alpha =1$ fixed, which is the typical way to treat this limit and which represents convergence to a uniform channel of width 2, for ![]() $\alpha$ in radians. We previously scaled lengths by

$\alpha$ in radians. We previously scaled lengths by ![]() $L_0$ to set the eddy of interest to

$L_0$ to set the eddy of interest to ![]() $r=1$, so to scale this eddy instead to

$r=1$, so to scale this eddy instead to ![]() $r=1/\alpha$ requires a length scale of

$r=1/\alpha$ requires a length scale of ![]() $\tilde {L}=\alpha L_0$, giving a new Bingham number

$\tilde {L}=\alpha L_0$, giving a new Bingham number ![]() $\widetilde {\textit {Bi}}=\tau _Y \tilde {L}/(\mu U_0)=\alpha \textit {Bi}$. We anticipate that the corresponding scaled critical Bingham number,

$\widetilde {\textit {Bi}}=\tau _Y \tilde {L}/(\mu U_0)=\alpha \textit {Bi}$. We anticipate that the corresponding scaled critical Bingham number, ![]() $\widetilde {\textit {Bi}}_c=\alpha \textit {Bi}_c$, is finite in the controlled limit, representing the Bingham number at which a new eddy forms between parallel plates, and from the heuristic calculation above, we find that

$\widetilde {\textit {Bi}}_c=\alpha \textit {Bi}_c$, is finite in the controlled limit, representing the Bingham number at which a new eddy forms between parallel plates, and from the heuristic calculation above, we find that

is the critical Bingham number for this limit. In fact this limit can be tackled directly by considering the eddy flow between parallel plates, as is demonstrated in Appendix B.

Figure 5. Examples of solutions before (a–d) and after (e–h) a new eddy has formed. The dotted line shows the dividing streamline ![]() $\psi _V=0$ from the corresponding Moffatt solutions while the red lines show the semi-circles considered in § 4.1.

$\psi _V=0$ from the corresponding Moffatt solutions while the red lines show the semi-circles considered in § 4.1.

Figure 6. (a) Torque, ![]() $G$, acting on the vertical radius of the semi-circle considered in § 4.1 using the corresponding Moffatt solution (dotted) and from the viscoplastic numerical simulations shown in the top row of figure 5 (stars), as a function of the wedge half-angle,

$G$, acting on the vertical radius of the semi-circle considered in § 4.1 using the corresponding Moffatt solution (dotted) and from the viscoplastic numerical simulations shown in the top row of figure 5 (stars), as a function of the wedge half-angle, ![]() $\alpha$. (b) The corresponding critical Bingham number,

$\alpha$. (b) The corresponding critical Bingham number, ![]() $\textit {Bi}_c$, calculated from (4.2) (solid line), as a function of the wedge half-angle,

$\textit {Bi}_c$, calculated from (4.2) (solid line), as a function of the wedge half-angle, ![]() $\alpha$. The red dotted line shows the divergent behaviour as

$\alpha$. The red dotted line shows the divergent behaviour as ![]() $\alpha \to 0$, given by

$\alpha \to 0$, given by ![]() $\textit {Bi}_c\sim 0.0022/\alpha$, while the stars indicate the smallest Bingham numbers of numerical simulations in which the new eddy has not yet opened up (and, hence, represent numerical upper bounds for

$\textit {Bi}_c\sim 0.0022/\alpha$, while the stars indicate the smallest Bingham numbers of numerical simulations in which the new eddy has not yet opened up (and, hence, represent numerical upper bounds for ![]() $\textit {Bi}_c$).

$\textit {Bi}_c$).

Using ![]() $x_0$,

$x_0$, ![]() $R$ and

$R$ and ![]() $\textit {Bi}_c$ we can also give a heuristic approximation for the extent,

$\textit {Bi}_c$ we can also give a heuristic approximation for the extent, ![]() $d$, of the static plug in the corner of the wedge, measured along the

$d$, of the static plug in the corner of the wedge, measured along the ![]() $\theta =0$ plane, as a function of

$\theta =0$ plane, as a function of ![]() $\textit {Bi}$. We have

$\textit {Bi}$. We have ![]() $d\approx x_0$ as

$d\approx x_0$ as ![]() $\textit {Bi}\to \textit {Bi}_c$ from above, and

$\textit {Bi}\to \textit {Bi}_c$ from above, and ![]() $d\approx x_0-R=x_0(1-\sin \alpha )$ as

$d\approx x_0-R=x_0(1-\sin \alpha )$ as ![]() $\textit {Bi}\to \textit {Bi}_c$ from below. We can then use self-similarity with the scale factors given in § 2 to scale up/down to the values of

$\textit {Bi}\to \textit {Bi}_c$ from below. We can then use self-similarity with the scale factors given in § 2 to scale up/down to the values of ![]() $d$ and

$d$ and ![]() $\textit {Bi}$ at the start of the eddy further from/nearer to the vertex. Specifically, this gives four points on the

$\textit {Bi}$ at the start of the eddy further from/nearer to the vertex. Specifically, this gives four points on the ![]() $\textit {Bi}-d$ curve:

$\textit {Bi}-d$ curve:

\begin{equation}

\left.\begin{gathered} A=\left(\textit{Bi}_c, x_0(1-\sin\alpha)\right),\quad B= \left(\textit{Bi}_c, x_0\right), \\

C=\left(\exp({\left(\lambda_r-2\right){\rm \pi}/\lambda_i})\textit{Bi}_c, \exp({{\rm \pi}/\lambda_i})x_0(1-\sin\alpha)\right), \\

\qquad D= \left(\exp({\left(\lambda_r-2\right){\rm \pi}/\lambda_i}) \textit{Bi}_c, \exp({{\rm \pi}/\lambda_i})x_0\right) , \end{gathered}\right\}

\end{equation}

\begin{equation}

\left.\begin{gathered} A=\left(\textit{Bi}_c, x_0(1-\sin\alpha)\right),\quad B= \left(\textit{Bi}_c, x_0\right), \\

C=\left(\exp({\left(\lambda_r-2\right){\rm \pi}/\lambda_i})\textit{Bi}_c, \exp({{\rm \pi}/\lambda_i})x_0(1-\sin\alpha)\right), \\

\qquad D= \left(\exp({\left(\lambda_r-2\right){\rm \pi}/\lambda_i}) \textit{Bi}_c, \exp({{\rm \pi}/\lambda_i})x_0\right) , \end{gathered}\right\}

\end{equation}

where ![]() $A$ to

$A$ to ![]() $B$ and

$B$ and ![]() $C$ to

$C$ to ![]() $D$ are vertical jumps occurring at the formation/disappearance of an eddy, while between

$D$ are vertical jumps occurring at the formation/disappearance of an eddy, while between ![]() $B$ and

$B$ and ![]() $C$,

$C$, ![]() $d$ is a continuous, increasing function of

$d$ is a continuous, increasing function of ![]() $\textit {Bi}$. The form of this function is shown, from numerical solutions for

$\textit {Bi}$. The form of this function is shown, from numerical solutions for ![]() $\alpha =20^{\circ }$, in figure 4a), but for the purposes of a simple approximation, linear interpolation can be used between points

$\alpha =20^{\circ }$, in figure 4a), but for the purposes of a simple approximation, linear interpolation can be used between points ![]() $B$ and

$B$ and ![]() $C$. Figure 4 shows good agreement between this heuristic approximation and the numerical simulations, despite its simplicity.

$C$. Figure 4 shows good agreement between this heuristic approximation and the numerical simulations, despite its simplicity.

4.2. Flow fields when  $0<\textit {Bi}_c-\textit {Bi}\ll 1$

$0<\textit {Bi}_c-\textit {Bi}\ll 1$

Slightly below the yield stress at which a new eddy forms, a thin layer of yielded fluid separates the static corner plug from the rotating semi-circular plug, meaning we can employ a boundary layer analysis similar to those detailed by Balmforth et al. (Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017), Hewitt & Balmforth (Reference Hewitt and Balmforth2018) and Taylor-West & Hogg (Reference Taylor-West and Hogg2021). This boundary layer analysis will determine the scalings of the width of the yielded layer and the rotation rate of the rotating plug, with the difference between the Bingham number and ![]() $Bi_c$. In fact there are two distinct boundary layer scalings with one applying between the rotating plug and the rigid boundary and another between the static and rotating plugs. The former is asymptotically thinner than the latter; in the former, the viscous shear stresses provide the leading-order contribution to the torque balance on the rotating plug, whereas in the latter, plastic stresses are non-negligible.

$Bi_c$. In fact there are two distinct boundary layer scalings with one applying between the rotating plug and the rigid boundary and another between the static and rotating plugs. The former is asymptotically thinner than the latter; in the former, the viscous shear stresses provide the leading-order contribution to the torque balance on the rotating plug, whereas in the latter, plastic stresses are non-negligible.

Figure 7 shows a schematic of the boundary layer geometry. The governing small parameter is ![]() $\Delta \textit {Bi}=\textit {Bi}_c-\textit {Bi}$, which we refer to as the Bingham number deficit, and there are a number of quantities that scale with this quantity: the boundary layer thickness between the wall and the rotating plug,

$\Delta \textit {Bi}=\textit {Bi}_c-\textit {Bi}$, which we refer to as the Bingham number deficit, and there are a number of quantities that scale with this quantity: the boundary layer thickness between the wall and the rotating plug, ![]() $\epsilon _1$; the boundary layer thickness between the rotating plug and stagnant corner plug,

$\epsilon _1$; the boundary layer thickness between the rotating plug and stagnant corner plug, ![]() $\epsilon _2$; and the rotation rate of the rotating plug,

$\epsilon _2$; and the rotation rate of the rotating plug, ![]() $\varOmega$. Note there is also a short section of wider boundary layer after the narrow section where the boundary layer meets the adjacent eddy. The width here is also

$\varOmega$. Note there is also a short section of wider boundary layer after the narrow section where the boundary layer meets the adjacent eddy. The width here is also ![]() $O(\epsilon _2)$ but we will neglect this section for the clarity of the following discussion, appealing to the shortness of the region to justify this decision. The direction of rotation depends on which eddy is being considered, but we will assume clockwise rotation, as relevant to the first new eddy to form as

$O(\epsilon _2)$ but we will neglect this section for the clarity of the following discussion, appealing to the shortness of the region to justify this decision. The direction of rotation depends on which eddy is being considered, but we will assume clockwise rotation, as relevant to the first new eddy to form as ![]() $\textit {Bi}$ is decreased as in figure 2. Following the construction of Balmforth et al. (Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017), we take curvilinear coordinates,

$\textit {Bi}$ is decreased as in figure 2. Following the construction of Balmforth et al. (Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017), we take curvilinear coordinates, ![]() $(s,n)$, and velocities,

$(s,n)$, and velocities, ![]() $(u_s,u_n)$, along and across the boundary layer (although we note that polar coordinates would also be an appropriate choice here), where

$(u_s,u_n)$, along and across the boundary layer (although we note that polar coordinates would also be an appropriate choice here), where ![]() $s=0$ at the axis of symmetry of the wedge. The full system of equations are then (see, e.g. Balmforth et al. Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017)

$s=0$ at the axis of symmetry of the wedge. The full system of equations are then (see, e.g. Balmforth et al. Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017)

where ![]() $\kappa$ is the curvature of the boundary layer. For an approximately circular boundary layer, we have

$\kappa$ is the curvature of the boundary layer. For an approximately circular boundary layer, we have ![]() $\kappa \approx -{1}/{R}$ (with the sign determined from the orientation of the coordinate axes).

$\kappa \approx -{1}/{R}$ (with the sign determined from the orientation of the coordinate axes).

Figure 7. Schematic of boundary layer geometry shortly after a new eddy has formed. The grey regions are unyielded fluid, and the central plug is in clockwise solid-body rotation around the point ![]() $O$ with rotation rate

$O$ with rotation rate ![]() $\varOmega$.

$\varOmega$.

The components of strain rate and deviatoric stress are given by

In each of the boundary layer regions, ![]() $j=1$ and

$j=1$ and ![]() $2$, we define scaled coordinates and velocities by

$2$, we define scaled coordinates and velocities by

where ![]() $u_s$ is scaled by the velocity of the rotating yield surface, and

$u_s$ is scaled by the velocity of the rotating yield surface, and ![]() $u_n$ is scaled accordingly from the conservation of mass, (4.5). Retaining only potentially leading-order terms we find that

$u_n$ is scaled accordingly from the conservation of mass, (4.5). Retaining only potentially leading-order terms we find that

where the sign of the first term on the right-hand side of (4.11) is due to the clockwise rotation of the rotating plug and we note that ![]() $R$ and

$R$ and ![]() $Bi$ are

$Bi$ are ![]() $O(1)$ as

$O(1)$ as ![]() $\Delta \textit {Bi}\to 0$. To account for the curvature term in (4.6), we write the pressure in each region as

$\Delta \textit {Bi}\to 0$. To account for the curvature term in (4.6), we write the pressure in each region as

With this substitution we find that, to leading order, (4.6) and (4.7) are given by

$$\begin{gather}

\frac{\partial P}{\partial s}\!=\!\frac{\partial^{2} U_s}{\partial \eta_j^{2}}\!+\!2\frac{\epsilon_j^{3}\textit{Bi}}{R\varOmega} \frac{\partial}{\partial\eta_j}\left(\left(\frac{\partial

U_s}{\partial s}\right)^{2}\left(\frac{\partial U_s} {\partial \eta_j}\right)^{{-}2}\right) \!-\!2\frac{\textit{Bi}\epsilon_j^{3}}{R\varOmega}\frac{\partial}{\partial

s}\left(\left(\frac{\partial U_s}{\partial

s}\right)\left(\frac{\partial U_s}{\partial

\eta_j}\right)^{{-}1}\right)+\dots,

\end{gather}$$

$$\begin{gather}

\frac{\partial P}{\partial s}\!=\!\frac{\partial^{2} U_s}{\partial \eta_j^{2}}\!+\!2\frac{\epsilon_j^{3}\textit{Bi}}{R\varOmega} \frac{\partial}{\partial\eta_j}\left(\left(\frac{\partial

U_s}{\partial s}\right)^{2}\left(\frac{\partial U_s} {\partial \eta_j}\right)^{{-}2}\right) \!-\!2\frac{\textit{Bi}\epsilon_j^{3}}{R\varOmega}\frac{\partial}{\partial

s}\left(\left(\frac{\partial U_s}{\partial

s}\right)\left(\frac{\partial U_s}{\partial

\eta_j}\right)^{{-}1}\right)+\dots,

\end{gather}$$ $$\begin{gather}\frac{\partial P}{\partial \eta_j}=2\frac{\textit{Bi}\epsilon_j^{3}}{R\varOmega}\frac{\partial}{\partial\eta_j}\left(\left(\frac{\partial U_s}{\partial s}\right)\left(\frac{\partial U_s}{\partial \eta_j}\right)^{{-}1}\right)+\dots. \end{gather}$$

$$\begin{gather}\frac{\partial P}{\partial \eta_j}=2\frac{\textit{Bi}\epsilon_j^{3}}{R\varOmega}\frac{\partial}{\partial\eta_j}\left(\left(\frac{\partial U_s}{\partial s}\right)\left(\frac{\partial U_s}{\partial \eta_j}\right)^{{-}1}\right)+\dots. \end{gather}$$

There are now two possible regimes in which viscous terms enter the momentum balance. Assuming ![]() $\epsilon _j^{3}/\varOmega \ll 1$, we have

$\epsilon _j^{3}/\varOmega \ll 1$, we have ![]() $\partial P/\partial \eta _j=0$ to leading order and

$\partial P/\partial \eta _j=0$ to leading order and

giving a quadratic profile for ![]() $U_s$. This situation applies for

$U_s$. This situation applies for ![]() $j=1$, where one side of the boundary layer is bounded by a rigid wall, but impossible for

$j=1$, where one side of the boundary layer is bounded by a rigid wall, but impossible for ![]() $j=2$ since the strain rate

$j=2$ since the strain rate ![]() $\partial U_s/\partial \eta _2$ must vanish at two distinct points, namely at both sides of the boundary layer, where it meets unyielded fluid. Hence, in the thinner region of the boundary layer we have

$\partial U_s/\partial \eta _2$ must vanish at two distinct points, namely at both sides of the boundary layer, where it meets unyielded fluid. Hence, in the thinner region of the boundary layer we have ![]() $\epsilon _1^{3}/\varOmega \ll 1$, with the exact scaling undetermined until later, while in the wider region we have

$\epsilon _1^{3}/\varOmega \ll 1$, with the exact scaling undetermined until later, while in the wider region we have

and a boundary layer solution governed by the partial differential equation derived by Oldroyd (Reference Oldroyd1947)

\begin{equation} \frac{\partial}{\partial\eta_2}\left(\frac{\partial U_s}{\partial \eta_2}+2\left(\frac{\partial U_s}{\partial s}\right)^{2}\left(\frac{\partial U_s}{\partial \eta_2}\right)^{{-}2}\right)-4\frac{\partial}{\partial s}\left(\left(\frac{\partial U_s}{\partial s}\right)\left(\frac{\partial U_s}{\partial \eta_2}\right)^{{-}1}\right)=F(s)\end{equation}

\begin{equation} \frac{\partial}{\partial\eta_2}\left(\frac{\partial U_s}{\partial \eta_2}+2\left(\frac{\partial U_s}{\partial s}\right)^{2}\left(\frac{\partial U_s}{\partial \eta_2}\right)^{{-}2}\right)-4\frac{\partial}{\partial s}\left(\left(\frac{\partial U_s}{\partial s}\right)\left(\frac{\partial U_s}{\partial \eta_2}\right)^{{-}1}\right)=F(s)\end{equation}

for some function of integration, ![]() $F(s)$. In both sections of the boundary layer (

$F(s)$. In both sections of the boundary layer (![]() $\,j=1,2$) we have boundary conditions

$\,j=1,2$) we have boundary conditions

where ![]() $\eta _j^{+}$ and

$\eta _j^{+}$ and ![]() $\eta _j^{-}$ are the limits of the boundary layer, and in the wider section of the boundary layer, where the layer is sandwiched between regions of unyielded fluid, we have the additional boundary condition

$\eta _j^{-}$ are the limits of the boundary layer, and in the wider section of the boundary layer, where the layer is sandwiched between regions of unyielded fluid, we have the additional boundary condition

In the thinner region of the boundary layer, we integrate (4.16) and apply the boundary conditions to find

\begin{equation} U_s=\frac{1}{2}\frac{\textrm{d}P}{\textrm{d}s}\left(\left(\eta_1^{+}-\eta_1\right)^{2}-2\left(\eta_1^{+}-\eta_1^{-}\right)\left(\eta_1^{+}-\eta_1\right)\right), \quad \frac{\textrm{d}P}{\textrm{d}s}={-}\frac{2}{\left(\eta_1^{+}-\eta_1^{-}\right)^{2}}. \end{equation}

\begin{equation} U_s=\frac{1}{2}\frac{\textrm{d}P}{\textrm{d}s}\left(\left(\eta_1^{+}-\eta_1\right)^{2}-2\left(\eta_1^{+}-\eta_1^{-}\right)\left(\eta_1^{+}-\eta_1\right)\right), \quad \frac{\textrm{d}P}{\textrm{d}s}={-}\frac{2}{\left(\eta_1^{+}-\eta_1^{-}\right)^{2}}. \end{equation}Conservation of mass imposes an additional constraint

\begin{equation} \frac{\textrm{d}}{\textrm{d}s}\int_{\eta_1^{-}}^{\eta_1^{+}}U_s\,\textrm{d}\eta={-}\frac{\textrm{d}\eta_1^{-}}{\textrm{d}s}, \end{equation}

\begin{equation} \frac{\textrm{d}}{\textrm{d}s}\int_{\eta_1^{-}}^{\eta_1^{+}}U_s\,\textrm{d}\eta={-}\frac{\textrm{d}\eta_1^{-}}{\textrm{d}s}, \end{equation}

representing the fact that divergence of the flux must be accounted for by flow through the boundaries of the boundary layer. This gives ![]() $\eta _1^{-}$ in terms of

$\eta _1^{-}$ in terms of ![]() $\eta _1^{+}$ as

$\eta _1^{+}$ as

where ![]() $W_0$ is a constant of integration and is

$W_0$ is a constant of integration and is ![]() $O(1)$. Since

$O(1)$. Since ![]() $\eta _1^{+}$ is given by the fixed position of the wall, it is a known function of

$\eta _1^{+}$ is given by the fixed position of the wall, it is a known function of ![]() $s$. In the vicinity of the point at which the semi-circle meets the rigid boundary,

$s$. In the vicinity of the point at which the semi-circle meets the rigid boundary, ![]() $s\approx s_0=R({\rm \pi} /2-\alpha )$, we have

$s\approx s_0=R({\rm \pi} /2-\alpha )$, we have

to leading order. Thus, we interpret ![]() $W_0$ as the width of the boundary layer at

$W_0$ as the width of the boundary layer at ![]() $s=s_0$, in boundary layer coordinates.

$s=s_0$, in boundary layer coordinates.

Since the pressure vanishes at the wedge's axis of symmetry by anti-symmetry, the total pressure change along the boundary layers is ![]() $O(1)$, given by the pressure at the point where the boundary layer meets the adjacent eddy – and here the solution remains unchanged to leading order by small changes in the Bingham number,

$O(1)$, given by the pressure at the point where the boundary layer meets the adjacent eddy – and here the solution remains unchanged to leading order by small changes in the Bingham number, ![]() $\Delta \textit {Bi}$. The contribution to the pressure gradient along the boundary layer,

$\Delta \textit {Bi}$. The contribution to the pressure gradient along the boundary layer, ![]() $\partial p/\partial s$, due to the curvature of the boundary layer is

$\partial p/\partial s$, due to the curvature of the boundary layer is ![]() $-2\textit {Bi}/R=O(1)$. This is the leading-order contribution in the wider sections of the boundary layer, and contributes a total pressure drop of

$-2\textit {Bi}/R=O(1)$. This is the leading-order contribution in the wider sections of the boundary layer, and contributes a total pressure drop of ![]() $-{\rm \pi} \textit {Bi}$ over the length of the boundary layer. In general this does not match the pressure where the boundary layer meets the fully yielded adjacent eddy (see, e.g. figure 8b) and, thus, we require an additional

$-{\rm \pi} \textit {Bi}$ over the length of the boundary layer. In general this does not match the pressure where the boundary layer meets the fully yielded adjacent eddy (see, e.g. figure 8b) and, thus, we require an additional ![]() $O(1)$ pressure jump along the thinner section of the boundary layer. This is only possible if the dominant contribution to the pressure gradient,

$O(1)$ pressure jump along the thinner section of the boundary layer. This is only possible if the dominant contribution to the pressure gradient, ![]() $\partial p/\partial s$, in the thinner section of the boundary layer is due to the second term in (4.13). Substituting for

$\partial p/\partial s$, in the thinner section of the boundary layer is due to the second term in (4.13). Substituting for ![]() $\eta _1^{+}$ we find that

$\eta _1^{+}$ we find that

\begin{equation} \frac{\textrm{d}P}{\textrm{d}s}={-}\frac{2}{\left(W_0+\dfrac{3\left(s-s_0\right)^{2}} {2\epsilon_1R}\right)^{2}},\end{equation}

\begin{equation} \frac{\textrm{d}P}{\textrm{d}s}={-}\frac{2}{\left(W_0+\dfrac{3\left(s-s_0\right)^{2}} {2\epsilon_1R}\right)^{2}},\end{equation}

which is ![]() $O(1)$ over the region where

$O(1)$ over the region where ![]() $s-s_0=O(\sqrt {\epsilon _1})$, and decays outside this region. Hence, the total pressure drop over the thinner region is

$s-s_0=O(\sqrt {\epsilon _1})$, and decays outside this region. Hence, the total pressure drop over the thinner region is ![]() $O(\sqrt {\epsilon _1}R\varOmega /\epsilon _1^{2})$. In fact, we can integrate (4.25) analytically to obtain the leading-order pressure drop over the thinner region as

$O(\sqrt {\epsilon _1}R\varOmega /\epsilon _1^{2})$. In fact, we can integrate (4.25) analytically to obtain the leading-order pressure drop over the thinner region as

In either case, we conclude that

Figure 8. (a) Rotation rate ![]() $\varOmega$ as a function of

$\varOmega$ as a function of ![]() $\textit {Bi}$ for

$\textit {Bi}$ for ![]() $\alpha =20^{\circ }$, measured in numerical simulations (stars) and the scaling relationship

$\alpha =20^{\circ }$, measured in numerical simulations (stars) and the scaling relationship ![]() $\varOmega ^{(2/3)}\sim \textit {Bi}_c-\textit {Bi}$. The horizontal dashed line shows

$\varOmega ^{(2/3)}\sim \textit {Bi}_c-\textit {Bi}$. The horizontal dashed line shows ![]() $\varOmega _V^{(2/3)}$, where

$\varOmega _V^{(2/3)}$, where ![]() $\varOmega _V$ is the rotation rate at the point where the strain rate vanishes in the viscous solution. (b) Pressure,

$\varOmega _V$ is the rotation rate at the point where the strain rate vanishes in the viscous solution. (b) Pressure, ![]() $p$, as a function of the coordinate along the boundary layer,

$p$, as a function of the coordinate along the boundary layer, ![]() $s$, for three values of the Bingham number deficit,

$s$, for three values of the Bingham number deficit, ![]() $\Delta \textit {Bi}$, indicated in the legend. The black dotted line shows the constant gradient

$\Delta \textit {Bi}$, indicated in the legend. The black dotted line shows the constant gradient ![]() $-2\textit {Bi}_c/R$ predicted in the thicker section of the boundary layer for small

$-2\textit {Bi}_c/R$ predicted in the thicker section of the boundary layer for small ![]() $\Delta \textit {Bi}$, and the vertical grey dashed line marks the narrowest point of the boundary layer.

$\Delta \textit {Bi}$, and the vertical grey dashed line marks the narrowest point of the boundary layer.

Finally, we consider the additional torque along the circular arc, above that provided by the yield stress, given by

where ![]() $G(\textit {Bi})$ again represents the torque acting on the upper half of the diameter of the semi-circle due to normal stresses in the yielded flow to the right of the plug (see (4.1)), and is substituted for

$G(\textit {Bi})$ again represents the torque acting on the upper half of the diameter of the semi-circle due to normal stresses in the yielded flow to the right of the plug (see (4.1)), and is substituted for ![]() $-\int _0^{R{\rm \pi} /2}R\tau _{sn}\,\textrm {d}s$ by torque balance. Since this diameter lies primarily in the adjacent eddy, in which the solution varies smoothly with

$-\int _0^{R{\rm \pi} /2}R\tau _{sn}\,\textrm {d}s$ by torque balance. Since this diameter lies primarily in the adjacent eddy, in which the solution varies smoothly with ![]() $\textit {Bi}$, we can use a Taylor series to write

$\textit {Bi}$, we can use a Taylor series to write

and, thus,

Substituting for ![]() $\tau _{sn}$ from (4.11), and using (4.17), the contributions to this additional torque from region 2 is

$\tau _{sn}$ from (4.11), and using (4.17), the contributions to this additional torque from region 2 is ![]() $O(\varOmega /\epsilon _2)=O(\varOmega ^{2/3})$. In region 1, similarly to the pressure gradient, the viscous shear stress is dominated by a region of length

$O(\varOmega /\epsilon _2)=O(\varOmega ^{2/3})$. In region 1, similarly to the pressure gradient, the viscous shear stress is dominated by a region of length ![]() $O(\sqrt {\epsilon _1})$ where

$O(\sqrt {\epsilon _1})$ where ![]() $\partial U_s/\partial \eta _1=O(1)$. And hence, using (4.11) and (4.27), the additional torque from region 1 is

$\partial U_s/\partial \eta _1=O(1)$. And hence, using (4.11) and (4.27), the additional torque from region 1 is ![]() $O(\sqrt {\epsilon _1}\varOmega /\epsilon _1)=O(\varOmega ^{2/3})$, as for region 2. Thus,

$O(\sqrt {\epsilon _1}\varOmega /\epsilon _1)=O(\varOmega ^{2/3})$, as for region 2. Thus, ![]() $\Delta \textit {Bi}\sim \varOmega ^{2/3}$, and we obtain the scalings

$\Delta \textit {Bi}\sim \varOmega ^{2/3}$, and we obtain the scalings

Figure 8 provides evidence for the validity of this boundary layer theory, from a sequence of numerical simulations for ![]() $\alpha =20^{\circ }$. We measure

$\alpha =20^{\circ }$. We measure ![]() $\varOmega$ as the rotation rate at the point on the wedge's symmetry axis at which the strain rate vanishes in the corresponding Moffatt (Reference Moffatt1964) solution. This point is always inside the central rotating plug in the viscoplastic solutions. The left panel shows how

$\varOmega$ as the rotation rate at the point on the wedge's symmetry axis at which the strain rate vanishes in the corresponding Moffatt (Reference Moffatt1964) solution. This point is always inside the central rotating plug in the viscoplastic solutions. The left panel shows how ![]() $\varOmega \sim \Delta \textit {Bi}^{3/2}$ when

$\varOmega \sim \Delta \textit {Bi}^{3/2}$ when ![]() $\textit {Bi}\to \textit {Bi}_c$ from below, and rises up to the rotation rate,

$\textit {Bi}\to \textit {Bi}_c$ from below, and rises up to the rotation rate, ![]() $\varOmega _V$, from the viscous, Moffatt solution, as

$\varOmega _V$, from the viscous, Moffatt solution, as ![]() $\textit {Bi}$ decreases. The right panel shows how pressure varies along the boundary layer, for three values of the Bingham number deficit,

$\textit {Bi}$ decreases. The right panel shows how pressure varies along the boundary layer, for three values of the Bingham number deficit, ![]() $\Delta \textit {Bi}$, verifying that the pressure gradient approaches the constant

$\Delta \textit {Bi}$, verifying that the pressure gradient approaches the constant ![]() $-2\textit {Bi}_c/R$ in the first, wider, part of the boundary layer, before becoming large in a short section of the layer, resulting in an

$-2\textit {Bi}_c/R$ in the first, wider, part of the boundary layer, before becoming large in a short section of the layer, resulting in an ![]() $O(1)$ overall pressure change, essentially independent of

$O(1)$ overall pressure change, essentially independent of ![]() $\Delta \textit {Bi}$.

$\Delta \textit {Bi}$.

In region 2 we can solve (4.18) by means of a similarity solution detailed by Balmforth et al. (Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017) and find that

where ![]() $\eta _2^{m}=(\eta _2^{+}+\eta _2^{-})/2$ is the mid-line of the boundary layer and

$\eta _2^{m}=(\eta _2^{+}+\eta _2^{-})/2$ is the mid-line of the boundary layer and ![]() $Y(s)=(\eta _2^{+}-\eta _2^{-})/2$ is its half-width, given implicitly by

$Y(s)=(\eta _2^{+}-\eta _2^{-})/2$ is its half-width, given implicitly by

\begin{equation} Y_E^{3/2}\left(\tan^{{-}1}\sqrt{\frac{Y/Y_E}{1-Y/Y_E}}-\sqrt{\frac{Y}{Y_E} \left(1-\frac{Y}{Y_E}\right)}\right)=\frac{\sqrt{3}}{2}\left(\tilde{s}_0-s\right). \end{equation}

\begin{equation} Y_E^{3/2}\left(\tan^{{-}1}\sqrt{\frac{Y/Y_E}{1-Y/Y_E}}-\sqrt{\frac{Y}{Y_E} \left(1-\frac{Y}{Y_E}\right)}\right)=\frac{\sqrt{3}}{2}\left(\tilde{s}_0-s\right). \end{equation}

Here ![]() $s=\tilde {s}_0$ is the apparent origin of the similarity solution, at which location

$s=\tilde {s}_0$ is the apparent origin of the similarity solution, at which location ![]() $Y(\tilde {s}_0)=0$, and

$Y(\tilde {s}_0)=0$, and ![]() $Y_E=(\sqrt {3}\tilde {s}_0/{\rm \pi} )^{2/3},$ is the maximum half-width of the boundary layer. Asymptotically, to leading order this section of the boundary layer must end at

$Y_E=(\sqrt {3}\tilde {s}_0/{\rm \pi} )^{2/3},$ is the maximum half-width of the boundary layer. Asymptotically, to leading order this section of the boundary layer must end at ![]() $s=s_0=R({\rm \pi} /2-\alpha )$ with vanishing width, and, hence, to leading order we must have

$s=s_0=R({\rm \pi} /2-\alpha )$ with vanishing width, and, hence, to leading order we must have ![]() $\tilde {s}_0=s_0$. The complete leading-order boundary layer solution would then be obtained by fixing the constants

$\tilde {s}_0=s_0$. The complete leading-order boundary layer solution would then be obtained by fixing the constants ![]() $W_0$ and

$W_0$ and ![]() $\varOmega _0$, where

$\varOmega _0$, where ![]() $\varOmega \sim \varOmega _0\Delta \textit {Bi}^{3/2}$, by enforcing both the pressure drop over region 1 and the torque over the entire boundary layer. This calculation requires additional detailed analysis of the fully yielded flow within the eddy adjacent to the boundary layers and is not attempted here. Instead, the boundary layer structure has revealed the asymptotic scalings of

$\varOmega \sim \varOmega _0\Delta \textit {Bi}^{3/2}$, by enforcing both the pressure drop over region 1 and the torque over the entire boundary layer. This calculation requires additional detailed analysis of the fully yielded flow within the eddy adjacent to the boundary layers and is not attempted here. Instead, the boundary layer structure has revealed the asymptotic scalings of ![]() $\epsilon _1$,

$\epsilon _1$, ![]() $\epsilon _2$ and

$\epsilon _2$ and ![]() $\varOmega$ upon the Bingham number deficit,

$\varOmega$ upon the Bingham number deficit, ![]() $\Delta \textit {Bi}$.

$\Delta \textit {Bi}$.

The predictions of boundary layer shape can also be compared with numerics by directly measuring the empirical rotation rate, ![]() $\varOmega$, radius of the rotating plug,

$\varOmega$, radius of the rotating plug, ![]() $R$, and widths of the boundary layer at

$R$, and widths of the boundary layer at ![]() $s=s_0$ and