1. Introduction

Gas-particle two-phase flow appears in chemical, petroleum, environmental and other industries. Quantitative study of the system is of great importance in both basic scientific research and practical industrial production (Marchisio & Fox Reference Marchisio and Fox2013; Ceresiat, Kolehmainen & Ozel Reference Ceresiat, Kolehmainen and Ozel2021). Most granular flow systems include multiple types of solid particles with different material densities, diameters, shapes, etc., which is named as the polydisperse gas-particle flow. For the polydisperse system, it may become problematic to regard all kinds of solid particles as a single phase, especially as particle properties differ significantly from each other. For instance, the inter-phase heat conduction and the rate of chemical reaction highly depend on the solid particle's size. As a result, the effect from the particle size distribution (PSD) cannot be ignored (Zhong et al. Reference Zhong, Yu, Zhou, Xie and Zhang2016; Yan et al. Reference Yan, Dong, Zhou and Luo2023). Besides, the mixing and segregation of different types of solid particles are important issues that deserve much attention in the chemical and food industries, and thus the numerical method for the multi-disperse particulate flow should be employed (Fox & Vedula Reference Fox and Vedula2010). In addition, the interaction between different types of solid particles, which is usually modelled by the so-called solid-to-solid drag, plays a significant role in predicting the particles’ behaviours, indicating the necessity of accurately modelling the polydisperse system (Syamlal Reference Syamlal1987; Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999). Therefore, developing an advanced computational fluid dynamics tool for polydisperse gas-particle flow is more challenging than its monodisperse counterparts due to the increased complexity in the multi-particle system (Zhang et al. Reference Zhang, Xu, Chang, Zhao, Wang and Ge2023).

Generally, two approaches, Eulerian–Eulerian (EE) approach and Eulerian–Lagrangian (EL) approach, are used for the study of gas-particle two-phase flow. In both approaches, the gas phase is described by the Navier–Stokes (NS) equations, i.e. the so-called Eulerian approach; while the treatment of the solid particle phase can be Eulerian or Lagrangian. In the EE approach, the particle phase is modelled as a continuum fluid, and the hydrodynamic solvers are used in the simulation (Gidaspow Reference Gidaspow1994; Saurel & Abgrall Reference Saurel and Abgrall1999; Lu & Gidaspow Reference Lu and Gidaspow2003). In the EL approach, all solid particles or parcels, standing for a group of solid particles with the same properties, are tracked individually by solving the Newtonian equation of particle motion. At the same time, the collisions between solid particles are modelled, such as these collision rules in the discrete element method (DEM) (Tsuji, Kawaguchi & Tanaka Reference Tsuji, Kawaguchi and Tanaka1993; Zhang et al. Reference Zhang, Zhao, Lu, Ge, Wang and Duan2017b) and in the multiphase particle-in-cell method (MP-PIC) (Snider Reference Snider2001, Reference Snider2007; Verma & Padding Reference Verma and Padding2020). In general, the EL approach works well in all flow regimes. Although the EE approach may not be able to accurately predict the particular flow when the Knudsen number (Kn) of the solid phase is large, it is still the dominant method in practical engineering applications due to the efficiency of the EE approach in comparison with the EL one (Zhong et al. Reference Zhong, Yu, Zhou, Xie and Zhang2016; Zhang et al. Reference Zhang, Xu, Chang, Zhao, Wang and Ge2023). However, the recent studies also show that at some points the EL approach may be more accurate and efficient than the finely resolved two-fluid EE model (Benyahia Reference Benyahia2022). In addition to the aforementioned methods, other commonly used numerical methods for granular flow include, but are not limited to, method of moment (Fan & Fox Reference Fan and Fox2008; Marchisio & Fox Reference Marchisio and Fox2013), direct simulation of Monte Carlo (He et al. Reference He, Zhao, Wang and Zheng2015), compressible multiphase particle-in-cell method (Tian et al. Reference Tian, Zeng, Meng, Chen, Guo and Xue2020) and hybrid EL method (Zhang et al. Reference Zhang, Wang, Lu, Liu, Wang and Zhao2017a), and many others.

For the solid particle evolution, the dynamics from the particle free transport with the interaction with the gas phase and inter-particle collisions should be modelled (Marchisio & Fox Reference Marchisio and Fox2013; Yang et al. Reference Yang, Wei, Shyy and Xu2023). For the polydisperse flow, the inter-particle collision includes the monodisperse and polydisperse types of particles. For the EL approach, such as DEM, the effect on the particle in the polydisperse case can be added straightforwardly in the simulation, since all solid particles’ transport will be tracked with the explicit inter-particle collision according to the collision law (Feng et al. Reference Feng, Xu, Zhang, Yu and Zulli2004; Zhang et al. Reference Zhang, Zhao, Lu, Ge, Wang and Duan2017b). However, the computational cost is high, especially at small Kn, due to the explicit tracking of tremendous amount of particles. For the EE approach, the multi-fluid strategy is one of the commonly adopted methods in the polydisperse flow study, where many sets of governing equations are employed to describe the disperse phases (Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999; Lu & Gidaspow Reference Lu and Gidaspow2003). For example, in the study of hydrodynamic behaviours from the PSD, the particle phase is modelled in different discrete phases according to the particle size (Qin, Zhou & Wang Reference Qin, Zhou and Wang2019). In the multi-fluid model, the closure of one solid phase will involve the properties of other disperse phases. It becomes crucially important to develop valid numerical methods for polydisperse gas-particle flow (Zhao & Wang Reference Zhao and Wang2021). The determination of the solid-to-solid drag in the momentum exchange between different disperse phases has to be properly modelled (Syamlal Reference Syamlal1987; Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999; Fan & Fox Reference Fan and Fox2008). Another approach is to use one set of governing equations for the whole solid phase, and additional modifications are added with the consideration of different particle sizes (Chen, Wang & Li Reference Chen, Wang and Li2013).

In addition, the gas–solid interaction also plays a significant role in monodisperse/polydisperse particular flow in both EE and EL approaches. In particular, the drag on a solid particle from the gas flow is of great importance to accurately predict the flow field of the gas-particle system (Li et al. Reference Li, Lan, Xu, Wang, Lu and Gao2009; Zhang et al. Reference Zhang, Zhao, Lu, Ge, Wang and Duan2017b). For example, different polydisperse drag models are compared to evaluate their performance in capturing the mixing and segregation of different dispersed solid flows (Zhang et al. Reference Zhang, Zhao, Lu, Ge, Wang and Duan2017b). Two methods are widely adopted to construct the drag model in the polydisperse system. Firstly, each disperse phase uses directly the drag model developed for monodisperse flow (Lu & Gidaspow Reference Lu and Gidaspow2003; Fan & Fox Reference Fan and Fox2008). Secondly, the total drag of the whole multi-disperse system is evaluated from either experiment or direct numerical simulation (DNS) and is distributed to individual disperse phases according to the interaction rule (Cello, Di Renzo & Di Maio Reference Cello, Di Renzo and Di Maio2010; Rong, Dong & Yu Reference Rong, Dong and Yu2014). It is worth mentioning that the mesoscale flow structures in the gas–solid system have a significant effect on the modelling of phase interaction. Particularly, the energy-minimization multiscale (EMMS) theory has been systematically developed for gas-particle flow (Li & Kwauk Reference Li and Kwauk1994; Yang et al. Reference Yang, Wang, Ge and Li2003; Wang & Li Reference Wang and Li2007). Recently, the EMMS has been developed and employed in the polydisperse particular flow system, with a preferred hydrodynamic performance in the EE approach (Qin et al. Reference Qin, Zhou and Wang2019). Besides, the filtered subgrid model is another important mesoscale method for both monodisperse and polydisperse gas-particle two-phase flows (Zhu et al. Reference Zhu, Ouyang, Lei and Luo2021; Lei, Zhu & Luo Reference Lei, Zhu and Luo2023). For example, the material property-dependent drag model presents satisfactory results in comparison with the experiment measurements (Zhu et al. Reference Zhu, Liu, Tang and Luo2019a).

The unified gas-kinetic wave–particle (UGKWP) method is able to simulate the equilibrium and non-equilibrium transports in different regimes under a unified framework. The multiscale gas-kinetic scheme (GKS)-UGKWP method for gas-particle two-phase flow is a regime-adaptive method to recover the EE and EL approaches in the limiting conditions (Yang et al. Reference Yang, Liu, Ji, Shyy and Xu2022b; Yang, Shyy & Xu Reference Yang, Shyy and Xu2022c; Yang et al. Reference Yang, Wei, Shyy and Xu2023). The UGKWP is an extension of the unified gas-kinetic scheme (UGKS). The UGKS models the flow physics directly on the scales of cell size and time step (Xu & Huang Reference Xu and Huang2010; Xu Reference Xu2021). The method was initially developed for rarefied flow and further extended to radiation transfer, plasma, particular flow, etc. (Sun, Jiang & Xu Reference Sun, Jiang and Xu2015; Liu & Xu Reference Liu and Xu2017; Liu, Wang & Xu Reference Liu, Wang and Xu2019). Both UGKS and UGKWP update macroscopic flow variables. However, different from the UGKS method with the update of the gas distribution function with the discretized particle velocity space in a deterministic way, the UGKWP method decomposes the distribution function into analytical wave and statistical particle, where the weights for the wave and particle depend on the local cell's Knudsen number (Kn), such as ![]() $(1-\exp (-1/\text {Kn}))$ for the wave component and

$(1-\exp (-1/\text {Kn}))$ for the wave component and ![]() $\exp (-1/\text {Kn})$ for the particle component. Due to the absence of a discretized particle velocity space, the UGKWP method increases its computational efficiency greatly in high-speed and high-temperature flow simulations, especially for flow simulation close to the equilibrium (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu, Zhu & Xu Reference Liu, Zhu and Xu2020). In the continuum flow regime, UGKWP gets back to the GKS (Xu Reference Xu2001, Reference Xu2021; Yang et al. Reference Yang, Ji, Shyy and Xu2022a), which is the kinetic theory-based second-order NS solver. The GKS is used directly to compute the gas phase in the current gas–solid particle system. Due to the Kn-dependent wave–particle decomposition, UGKWP is suitable for the simulation of particle flow. In the high particle collision regime with a small Kn, no particles will be sampled in UKGWP, and thus a hydrodynamic formulation will emerge for the evolution of the solid particle phase. The whole GKS-UGKWP will recover the EE approach automatically. On the contrary, when Kn is large, such as the collisionless regime for the solid particle phase, the evolution of the solid phase will be determined by tracking the discrete particles, and the GKS-UGKWP automatically gets back to the EL approach. At an intermediate Kn, both hydrodynamic wave and microscopic discrete particles will be updated in UGKWP for capturing the local non-equilibrium particle flow. In this paper, for the first time, the GKS-UGKWP is constructed to solve polydisperse gas-particle flow with multiple disperse particle phases, where particle's transport in the gas flow and particle collisions between same-type and different-type particles will be incorporated into the scheme.

$\exp (-1/\text {Kn})$ for the particle component. Due to the absence of a discretized particle velocity space, the UGKWP method increases its computational efficiency greatly in high-speed and high-temperature flow simulations, especially for flow simulation close to the equilibrium (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu, Zhu & Xu Reference Liu, Zhu and Xu2020). In the continuum flow regime, UGKWP gets back to the GKS (Xu Reference Xu2001, Reference Xu2021; Yang et al. Reference Yang, Ji, Shyy and Xu2022a), which is the kinetic theory-based second-order NS solver. The GKS is used directly to compute the gas phase in the current gas–solid particle system. Due to the Kn-dependent wave–particle decomposition, UGKWP is suitable for the simulation of particle flow. In the high particle collision regime with a small Kn, no particles will be sampled in UKGWP, and thus a hydrodynamic formulation will emerge for the evolution of the solid particle phase. The whole GKS-UGKWP will recover the EE approach automatically. On the contrary, when Kn is large, such as the collisionless regime for the solid particle phase, the evolution of the solid phase will be determined by tracking the discrete particles, and the GKS-UGKWP automatically gets back to the EL approach. At an intermediate Kn, both hydrodynamic wave and microscopic discrete particles will be updated in UGKWP for capturing the local non-equilibrium particle flow. In this paper, for the first time, the GKS-UGKWP is constructed to solve polydisperse gas-particle flow with multiple disperse particle phases, where particle's transport in the gas flow and particle collisions between same-type and different-type particles will be incorporated into the scheme.

This paper is organized as follows. Section 2 introduces the governing equations for the particle phase and the UGKWP method. Section 3 presents the governing equations for the gas phase and GKS method. Section 4 shows the numerical examples and the engineering applications with experimental measurements. The last section is the conclusion.

2. Unified gas-kinetic wave–particle method for disperse solid particle phase

2.1. Governing equation for disperse phase

The evolution of disperse phase is governed by the kinetic equation

\begin{equation} \frac{\partial f_{k}}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} (\boldsymbol{u}f_{k}) + \boldsymbol{\nabla}_{\boldsymbol{u}} \boldsymbol{\cdot} (\boldsymbol{a}f_{k}) = \frac{g_{k}-f_{k}}{\tau_{k}} + \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}, \end{equation}

\begin{equation} \frac{\partial f_{k}}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} (\boldsymbol{u}f_{k}) + \boldsymbol{\nabla}_{\boldsymbol{u}} \boldsymbol{\cdot} (\boldsymbol{a}f_{k}) = \frac{g_{k}-f_{k}}{\tau_{k}} + \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}, \end{equation}

where ![]() $f_{k}$ is the distribution function of the

$f_{k}$ is the distribution function of the ![]() $k$th disperse phase,

$k$th disperse phase, ![]() $\boldsymbol {u}$ is the particle velocity,

$\boldsymbol {u}$ is the particle velocity, ![]() $\boldsymbol {a}$ is the particle acceleration caused by the external force,

$\boldsymbol {a}$ is the particle acceleration caused by the external force, ![]() $\boldsymbol {\nabla }_{\boldsymbol {x}}$ is the divergence operator with respect to space,

$\boldsymbol {\nabla }_{\boldsymbol {x}}$ is the divergence operator with respect to space, ![]() $\boldsymbol {\nabla }_{\boldsymbol {u}}$ is the divergence operator with respect to velocity,

$\boldsymbol {\nabla }_{\boldsymbol {u}}$ is the divergence operator with respect to velocity, ![]() $\tau _k$ is the relaxation time for the

$\tau _k$ is the relaxation time for the ![]() $k$th disperse phase and

$k$th disperse phase and ![]() $g_{k}$ is the associated equilibrium distribution, which can be written as

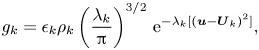

$g_{k}$ is the associated equilibrium distribution, which can be written as

\begin{equation} g_{k}=\epsilon_k\rho_k\left(\frac{\lambda_k}{\rm \pi}\right)^{{3}/{2}}\,{\rm e}^{-\lambda_k [(\boldsymbol{u}-\boldsymbol{U}_k)^2]}, \end{equation}

\begin{equation} g_{k}=\epsilon_k\rho_k\left(\frac{\lambda_k}{\rm \pi}\right)^{{3}/{2}}\,{\rm e}^{-\lambda_k [(\boldsymbol{u}-\boldsymbol{U}_k)^2]}, \end{equation}

where ![]() $\epsilon _k$ is the volume fraction of the

$\epsilon _k$ is the volume fraction of the ![]() $k$th disperse phase,

$k$th disperse phase, ![]() $\rho _k$ is the material density of the

$\rho _k$ is the material density of the ![]() $k$th disperse phase,

$k$th disperse phase, ![]() $\lambda _k$ is the variable relevant to the granular temperature

$\lambda _k$ is the variable relevant to the granular temperature ![]() $\theta _k$ with

$\theta _k$ with ![]() $\lambda _k = 1/(2\theta _k)$ and

$\lambda _k = 1/(2\theta _k)$ and ![]() $\boldsymbol {U}_k$ is the macroscopic velocity of the

$\boldsymbol {U}_k$ is the macroscopic velocity of the ![]() $k$th disperse phase. The second term at the right-hand side

$k$th disperse phase. The second term at the right-hand side ![]() $(g_{ik}-f_{k})/{\tau _{ik}}$ stands for the cross-species collision, where

$(g_{ik}-f_{k})/{\tau _{ik}}$ stands for the cross-species collision, where ![]() $N$ is the number of the solid disperse phase,

$N$ is the number of the solid disperse phase, ![]() $\tau _{ik}$ is the auxiliary collision time and

$\tau _{ik}$ is the auxiliary collision time and ![]() $g_{ik}$ is the auxiliary equilibrium distribution

$g_{ik}$ is the auxiliary equilibrium distribution

\begin{equation} g_{ik}=\epsilon_k\rho_k\left(\frac{\lambda_k}{\rm \pi}\right)^{{3}/{2}}\,{\rm e}^{-\lambda_k [(\boldsymbol{u}-\boldsymbol{U}_{ik})^2]}, \end{equation}

\begin{equation} g_{ik}=\epsilon_k\rho_k\left(\frac{\lambda_k}{\rm \pi}\right)^{{3}/{2}}\,{\rm e}^{-\lambda_k [(\boldsymbol{u}-\boldsymbol{U}_{ik})^2]}, \end{equation}

and note that the mass conservation for the cross-species collision can be satisfied automatically with the above ![]() $g_{ik}$.

$g_{ik}$.

The particle acceleration ![]() $\boldsymbol {a}$ is determined by the external forces, such as the drag force

$\boldsymbol {a}$ is determined by the external forces, such as the drag force ![]() $\boldsymbol {D}$, the buoyancy force

$\boldsymbol {D}$, the buoyancy force ![]() $\boldsymbol {F}_b$ and gravity

$\boldsymbol {F}_b$ and gravity ![]() $m_k\boldsymbol {G}$, etc. Particularly,

$m_k\boldsymbol {G}$, etc. Particularly, ![]() $\boldsymbol {D}$ and

$\boldsymbol {D}$ and ![]() $\boldsymbol {F}_b$ are inter-phase forces, standing for the force applied on the solid particles by the gas flow. The general form of drag force can be evaluated by the drag force model

$\boldsymbol {F}_b$ are inter-phase forces, standing for the force applied on the solid particles by the gas flow. The general form of drag force can be evaluated by the drag force model

In the numerical simulation, the ![]() $\tau _{st}$ in (2.4) will be closed by the drag model chosen for the solid phase, which will be introduced in detail later. Besides, another interactive force considered is the buoyancy force, which can be modelled as

$\tau _{st}$ in (2.4) will be closed by the drag model chosen for the solid phase, which will be introduced in detail later. Besides, another interactive force considered is the buoyancy force, which can be modelled as

where ![]() $p_g$ is the pressure of the gas phase.

$p_g$ is the pressure of the gas phase.

2.2. Unified gas-kinetic wave–particle method

In this subsection, the UGKWP for the evolution of disperse phase is introduced. Generally, the splitting operator is used to solve (2.1) through the following procedures within a numerical time step of the solid phase ![]() $\Delta t_s$:

$\Delta t_s$:

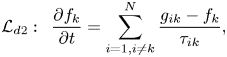

$$\begin{gather}\mathcal{L}_{d2} :\enspace \frac{\partial f_{k}}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}, \end{gather}$$

$$\begin{gather}\mathcal{L}_{d2} :\enspace \frac{\partial f_{k}}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}, \end{gather}$$

For brevity, the variables updated by ![]() $\mathcal {L}_{d1}$,

$\mathcal {L}_{d1}$, ![]() $\mathcal {L}_{d2}$ and

$\mathcal {L}_{d2}$ and ![]() $\mathcal {L}_{d3}$ are denoted as

$\mathcal {L}_{d3}$ are denoted as

Firstly, we focus on the part ![]() $\mathcal {L}_{d1}:\boldsymbol {W}^{n}\to \boldsymbol {W}^{*}$. The disperse phase kinetic equation without external force and cross-species collisions of solid particles is

$\mathcal {L}_{d1}:\boldsymbol {W}^{n}\to \boldsymbol {W}^{*}$. The disperse phase kinetic equation without external force and cross-species collisions of solid particles is

For brevity, the subscript ![]() $k$ will be neglected in this subsection. The integral solution of the kinetic equation can be written as

$k$ will be neglected in this subsection. The integral solution of the kinetic equation can be written as

where ![]() $\boldsymbol {x}'=\boldsymbol {x}+\boldsymbol {u}(t'-t)$ is the trajectory of the particle,

$\boldsymbol {x}'=\boldsymbol {x}+\boldsymbol {u}(t'-t)$ is the trajectory of the particle, ![]() $f_0$ is the initial distribution function at time

$f_0$ is the initial distribution function at time ![]() $t=0$ and

$t=0$ and ![]() $g$ is the corresponding equilibrium state. In UGKWP, both macroscopic conservative variables and microscopic distribution function will be updated under a finite volume framework. The cell-averaged macroscopic variables

$g$ is the corresponding equilibrium state. In UGKWP, both macroscopic conservative variables and microscopic distribution function will be updated under a finite volume framework. The cell-averaged macroscopic variables ![]() $\boldsymbol {W}_i$ of cell

$\boldsymbol {W}_i$ of cell ![]() $i$ are updated by the conservation law

$i$ are updated by the conservation law

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}_{ij}S_{ij} + \boldsymbol{S}_{i} \Delta t, \end{equation}

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}_{ij}S_{ij} + \boldsymbol{S}_{i} \Delta t, \end{equation}

where ![]() $\boldsymbol {W}_i=(\epsilon _i\rho _i, \epsilon _i\rho _i \boldsymbol {U}_i, \epsilon _i\rho _i E_i)$ are the cell-averaged macroscopic variables defined as

$\boldsymbol {W}_i=(\epsilon _i\rho _i, \epsilon _i\rho _i \boldsymbol {U}_i, \epsilon _i\rho _i E_i)$ are the cell-averaged macroscopic variables defined as

where ![]() $\epsilon _{i}\rho _iE_i = \frac {1}{2}\epsilon _{i}\rho _i \boldsymbol {U}_i^2 + \frac {3}{2}\epsilon _{i}\rho _i\theta _i$,

$\epsilon _{i}\rho _iE_i = \frac {1}{2}\epsilon _{i}\rho _i \boldsymbol {U}_i^2 + \frac {3}{2}\epsilon _{i}\rho _i\theta _i$, ![]() $\varOmega _i$ is the volume of cell

$\varOmega _i$ is the volume of cell ![]() $i$,

$i$, ![]() $\partial \varOmega _i$ denotes the set of cell interfaces of cell

$\partial \varOmega _i$ denotes the set of cell interfaces of cell ![]() $i$,

$i$, ![]() $S_{ij}$ is the area of the

$S_{ij}$ is the area of the ![]() $j$th interface of cell

$j$th interface of cell ![]() $i$ and

$i$ and ![]() $\boldsymbol {F}_{ij}$ denotes the fluxes for

$\boldsymbol {F}_{ij}$ denotes the fluxes for ![]() $\boldsymbol {W}_i$ passing through the interface

$\boldsymbol {W}_i$ passing through the interface ![]() $S_{ij}$. The flux

$S_{ij}$. The flux ![]() $\boldsymbol {F}_{ij}$ in one step

$\boldsymbol {F}_{ij}$ in one step ![]() $\Delta t$ can be calculated by

$\Delta t$ can be calculated by

where ![]() $\boldsymbol {n}_{ij}$ is the unit normal vector of interface

$\boldsymbol {n}_{ij}$ is the unit normal vector of interface ![]() $S_{ij}$,

$S_{ij}$, ![]() $f_{ij}(t)$ is the distribution function on the interface

$f_{ij}(t)$ is the distribution function on the interface ![]() $S_{ij}$ and

$S_{ij}$ and ![]() $\boldsymbol {\psi }=(1,\boldsymbol {u},\frac {1}{2}\boldsymbol {u}^2)^{\rm T}$. Here

$\boldsymbol {\psi }=(1,\boldsymbol {u},\frac {1}{2}\boldsymbol {u}^2)^{\rm T}$. Here

stands for the lost energy due to the inelastic collision of solid particles

where ![]() $e\in [0,1]$ is the restitution coefficient for the determination of the percentage of the lost energy in the inelastic collision, and

$e\in [0,1]$ is the restitution coefficient for the determination of the percentage of the lost energy in the inelastic collision, and ![]() $e$ has a value of 0.8, unless given specifically in this paper.

$e$ has a value of 0.8, unless given specifically in this paper.

Substituting the time-dependent distribution function (2.11) into (2.14), the fluxes can be rewritten as

\begin{align} \boldsymbol{F}_{ij} &=\int_{0}^{\Delta t} \int \boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} f_{ij}(\boldsymbol{x},t,\boldsymbol{u}) \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &=\int_{0}^{\Delta t} \int\boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} \left[ \frac{1}{\tau}\int_0^t g(\boldsymbol{x}',t',\boldsymbol{u})\,{\rm e}^{-(t-t')/\tau}\,\text{d}t' \right] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\quad +\int_{0}^{\Delta t} \int\boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} [ {\rm e}^{{-}t/\tau}f_0(\boldsymbol{x}-\boldsymbol{u}t,\boldsymbol{u})] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\overset{def}{=}\boldsymbol{F}^{eq}_{ij} + \boldsymbol{F}^{fr}_{ij}. \end{align}

\begin{align} \boldsymbol{F}_{ij} &=\int_{0}^{\Delta t} \int \boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} f_{ij}(\boldsymbol{x},t,\boldsymbol{u}) \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &=\int_{0}^{\Delta t} \int\boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} \left[ \frac{1}{\tau}\int_0^t g(\boldsymbol{x}',t',\boldsymbol{u})\,{\rm e}^{-(t-t')/\tau}\,\text{d}t' \right] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\quad +\int_{0}^{\Delta t} \int\boldsymbol{u}\boldsymbol{\cdot}\boldsymbol{n}_{ij} [ {\rm e}^{{-}t/\tau}f_0(\boldsymbol{x}-\boldsymbol{u}t,\boldsymbol{u})] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\overset{def}{=}\boldsymbol{F}^{eq}_{ij} + \boldsymbol{F}^{fr}_{ij}. \end{align} The procedure for obtaining the local equilibrium state ![]() $g_0$ at the cell interface and the construction of

$g_0$ at the cell interface and the construction of ![]() $g(t)$ are the same as that in GKS. For a second-order accuracy, the equilibrium state

$g(t)$ are the same as that in GKS. For a second-order accuracy, the equilibrium state ![]() $g$ around the cell interface is written as

$g$ around the cell interface is written as

where ![]() $\bar {\boldsymbol {a}}=[\overline {a_1}, \overline {a_2}, \overline {a_3}]^{\rm T}$,

$\bar {\boldsymbol {a}}=[\overline {a_1}, \overline {a_2}, \overline {a_3}]^{\rm T}$, ![]() $\overline {a_i}=({\partial g}/{\partial x_i})/g$,

$\overline {a_i}=({\partial g}/{\partial x_i})/g$, ![]() $i=1,2,3$,

$i=1,2,3$, ![]() $\bar {A}=({\partial g}/{\partial t})/g$ and

$\bar {A}=({\partial g}/{\partial t})/g$ and ![]() $g_0$ is the local equilibrium on the interface. Specifically, the coefficients of spatial derivatives

$g_0$ is the local equilibrium on the interface. Specifically, the coefficients of spatial derivatives ![]() $\overline {a_i}$ can be obtained from the corresponding derivatives of the macroscopic variables

$\overline {a_i}$ can be obtained from the corresponding derivatives of the macroscopic variables

where ![]() $i=1,2,3$, and

$i=1,2,3$, and ![]() $\langle \cdots \rangle$ means the moments of the Maxwellian distribution functions

$\langle \cdots \rangle$ means the moments of the Maxwellian distribution functions

The coefficients of temporal derivative ![]() $\bar {A}$ can be determined by the compatibility condition

$\bar {A}$ can be determined by the compatibility condition

Now, all the coefficients in the equilibrium state ![]() $g(\boldsymbol {x}',t',\boldsymbol {u})$ have been determined, and its integration becomes

$g(\boldsymbol {x}',t',\boldsymbol {u})$ have been determined, and its integration becomes

\begin{align} &f^{eq}(\boldsymbol{x},t,\boldsymbol{u}) \overset{def}{=} \frac{1}{\tau} \int_0^t g(\boldsymbol{x}',t',\boldsymbol{u})\,{\rm e}^{-(t-t')/\tau}\,\text{d}t' \nonumber\\ &\quad = c_1 g_0(\boldsymbol{x},\boldsymbol{u}) + c_2 \bar{\boldsymbol{a}} \boldsymbol{\cdot} \boldsymbol{u} g_0(\boldsymbol{x},\boldsymbol{u}) + c_3 A g_0(\boldsymbol{x},\boldsymbol{u}), \end{align}

\begin{align} &f^{eq}(\boldsymbol{x},t,\boldsymbol{u}) \overset{def}{=} \frac{1}{\tau} \int_0^t g(\boldsymbol{x}',t',\boldsymbol{u})\,{\rm e}^{-(t-t')/\tau}\,\text{d}t' \nonumber\\ &\quad = c_1 g_0(\boldsymbol{x},\boldsymbol{u}) + c_2 \bar{\boldsymbol{a}} \boldsymbol{\cdot} \boldsymbol{u} g_0(\boldsymbol{x},\boldsymbol{u}) + c_3 A g_0(\boldsymbol{x},\boldsymbol{u}), \end{align}with coefficients

\begin{equation} \left.\begin{array}{c@{}}

c_1 = 1-{\rm e}^{{-}t/\tau}, \\ c_2 = (t+\tau)\,{\rm

e}^{{-}t/\tau}-\tau, \\ c_3 = t-\tau+\tau \,{\rm

e}^{{-}t/\tau}. \end{array}\right\}

\end{equation}

\begin{equation} \left.\begin{array}{c@{}}

c_1 = 1-{\rm e}^{{-}t/\tau}, \\ c_2 = (t+\tau)\,{\rm

e}^{{-}t/\tau}-\tau, \\ c_3 = t-\tau+\tau \,{\rm

e}^{{-}t/\tau}. \end{array}\right\}

\end{equation}

So, the flux from the equilibrium state ![]() $\boldsymbol {F}^{eq}_{ij}$ is given by

$\boldsymbol {F}^{eq}_{ij}$ is given by

Besides, the flux contribution from the particle's free transport is calculated by tracking the particles sampled from ![]() $f_0$. Therefore, the updating of the cell-averaged macroscopic variables can be written as

$f_0$. Therefore, the updating of the cell-averaged macroscopic variables can be written as

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{eq}_{ij}S_{ij} + \frac{\boldsymbol{w}_{i}^{fr}}{\varOmega_{i}} + \boldsymbol{S}_{i} \Delta t, \end{equation}

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{eq}_{ij}S_{ij} + \frac{\boldsymbol{w}_{i}^{fr}}{\varOmega_{i}} + \boldsymbol{S}_{i} \Delta t, \end{equation}

where ![]() $\boldsymbol {w}^{fr}_i$ is the net free streaming flow of cell

$\boldsymbol {w}^{fr}_i$ is the net free streaming flow of cell ![]() $i$, obtained by counting the sampled particle, and it stands for the flux contribution of the free streaming of particles.

$i$, obtained by counting the sampled particle, and it stands for the flux contribution of the free streaming of particles.

The evolution of the particle distribution can be written as

where ![]() $g^{+}$ is named as the hydrodynamic distribution function with the analytical formulation. The initial distribution function

$g^{+}$ is named as the hydrodynamic distribution function with the analytical formulation. The initial distribution function ![]() $f_0$ has a probability of

$f_0$ has a probability of ![]() $\textrm {e}^{-t/\tau }$ to free transport and

$\textrm {e}^{-t/\tau }$ to free transport and ![]() $(1-\textrm {e}^{-t/\tau })$ to collision with other particles. The post-collision particle satisfies the distribution

$(1-\textrm {e}^{-t/\tau })$ to collision with other particles. The post-collision particle satisfies the distribution ![]() $g^+(\boldsymbol {x},\boldsymbol {u},t)$. The free transport time before the first collision with other particles is denoted as

$g^+(\boldsymbol {x},\boldsymbol {u},t)$. The free transport time before the first collision with other particles is denoted as ![]() $t_c$, and then the cumulative distribution function of

$t_c$, and then the cumulative distribution function of ![]() $t_c$ is

$t_c$ is

and therefore ![]() $t_c$ can be sampled as

$t_c$ can be sampled as ![]() $t_c=-\tau \ln (\eta )$, where

$t_c=-\tau \ln (\eta )$, where ![]() $\eta$ is a random number generated from a uniform distribution

$\eta$ is a random number generated from a uniform distribution ![]() $U(0,1)$. Then, the free streaming time

$U(0,1)$. Then, the free streaming time ![]() $t_f$ for each particle is determined separately by

$t_f$ for each particle is determined separately by

where ![]() $\Delta t$ is the time step. Therefore, within one time step, all particles can be divided into two groups: the collisionless particle and the collisional particle, and they are determined by the relation between time step

$\Delta t$ is the time step. Therefore, within one time step, all particles can be divided into two groups: the collisionless particle and the collisional particle, and they are determined by the relation between time step ![]() $\Delta t$ and free streaming time

$\Delta t$ and free streaming time ![]() $t_f$. Specifically, if

$t_f$. Specifically, if ![]() $t_f=\Delta t$, this particle is collisionless, and its trajectory is fully tracked in the whole time step. On the contrary, if

$t_f=\Delta t$, this particle is collisionless, and its trajectory is fully tracked in the whole time step. On the contrary, if ![]() $t_f<\Delta t$, this particle is a collisional one, and its trajectory is tracked until

$t_f<\Delta t$, this particle is a collisional one, and its trajectory is tracked until ![]() $t_f$. The collisional particle will be eliminated at

$t_f$. The collisional particle will be eliminated at ![]() $t_f$ in the simulation and the associated mass, momentum and energy carried by this particle are merged into the macroscopic quantities in the relevant cell by counting its contribution through the fluxes across the cell interfaces. More specifically, the particle trajectory in the free streaming process within time interval

$t_f$ in the simulation and the associated mass, momentum and energy carried by this particle are merged into the macroscopic quantities in the relevant cell by counting its contribution through the fluxes across the cell interfaces. More specifically, the particle trajectory in the free streaming process within time interval ![]() $t\in [0, t_f]$ is tracked by

$t\in [0, t_f]$ is tracked by

The term ![]() $\boldsymbol {w}_{i}^{fr}$ can be calculated by counting the particles passing through the interfaces of cell

$\boldsymbol {w}_{i}^{fr}$ can be calculated by counting the particles passing through the interfaces of cell ![]() $i$

$i$

where ![]() $P(\partial \varOmega _{i}^{+})$ is the particle set moving into cell

$P(\partial \varOmega _{i}^{+})$ is the particle set moving into cell ![]() $i$ within one time step,

$i$ within one time step, ![]() $P(\partial \varOmega _{i}^{-})$ is the particle set moving out of cell

$P(\partial \varOmega _{i}^{-})$ is the particle set moving out of cell ![]() $i$,

$i$, ![]() $k$ is the particle index in the specific set and

$k$ is the particle index in the specific set and ![]() $\boldsymbol {\phi }_k=[m_{k}, m_{k}\boldsymbol {u}_k, \frac {1}{2}m_{k}(\boldsymbol {u}^2_k)]^\textrm {T}$ is the mass, momentum and energy carried by particle

$\boldsymbol {\phi }_k=[m_{k}, m_{k}\boldsymbol {u}_k, \frac {1}{2}m_{k}(\boldsymbol {u}^2_k)]^\textrm {T}$ is the mass, momentum and energy carried by particle ![]() $k$. Therefore,

$k$. Therefore, ![]() $\boldsymbol {w}_{i}^{fr}/\varOmega _{i}$ is the net conservative quantity caused by the free streaming of the tracked particles. Now, all the terms in (2.25) have been determined and the macroscopic variables

$\boldsymbol {w}_{i}^{fr}/\varOmega _{i}$ is the net conservative quantity caused by the free streaming of the tracked particles. Now, all the terms in (2.25) have been determined and the macroscopic variables ![]() $\boldsymbol {W}_i$ can be updated.

$\boldsymbol {W}_i$ can be updated.

All particles have been traced up to time ![]() $t_f$. The collisionless particle with

$t_f$. The collisionless particle with ![]() $t_f=\Delta t$ will survive at the end of the time step; while the collisional particle with

$t_f=\Delta t$ will survive at the end of the time step; while the collisional particle with ![]() $t_f<\Delta t$ will be deleted after its first collision and it is assumed to go to the equilibrium state in that cell. Therefore, the hydrodynamic macroscopic variables of the collisional particles in cell

$t_f<\Delta t$ will be deleted after its first collision and it is assumed to go to the equilibrium state in that cell. Therefore, the hydrodynamic macroscopic variables of the collisional particles in cell ![]() $i$ at the end of each time step can be directly obtained by

$i$ at the end of each time step can be directly obtained by

and ![]() $\boldsymbol {W}^p_i$ are the mass, momentum and energy of remaining collisionless particles in the cell. Here, the macroscopic variables

$\boldsymbol {W}^p_i$ are the mass, momentum and energy of remaining collisionless particles in the cell. Here, the macroscopic variables ![]() $\boldsymbol {W}^h_i$ account for all eliminated collisional particles, which can be re-sampled from

$\boldsymbol {W}^h_i$ account for all eliminated collisional particles, which can be re-sampled from ![]() $\boldsymbol {W}^h_i$ based on the Maxwellian distribution at the beginning of the next time step. Now, the updates of both macroscopic variables and the microscopic particles have been presented. The above method is the so-called unified gas-kinetic particle (UGKP) method.

$\boldsymbol {W}^h_i$ based on the Maxwellian distribution at the beginning of the next time step. Now, the updates of both macroscopic variables and the microscopic particles have been presented. The above method is the so-called unified gas-kinetic particle (UGKP) method.

The above UGKP can be further developed to get an optimized UGKWP method in terms of efficiency and memory reduction. In the UGKP method, all particles are divided into collisionless and collisional particles in each time step. The collisional particles are deleted after the first collision and re-sampled from ![]() $\boldsymbol {W}^h_i$ at the beginning of the next time step. However, only the collisionless portion of the re-sampled particles can survive in the next time step, and all re-sampled collisional ones will be deleted again. Fortunately, the transport fluxes from these collisional particles can be evaluated analytically without using particles. Therefore, we do not need to re-sample these collisional particles from

$\boldsymbol {W}^h_i$ at the beginning of the next time step. However, only the collisionless portion of the re-sampled particles can survive in the next time step, and all re-sampled collisional ones will be deleted again. Fortunately, the transport fluxes from these collisional particles can be evaluated analytically without using particles. Therefore, we do not need to re-sample these collisional particles from ![]() $\boldsymbol {W}^h_i$ at all. According to the cumulative distribution (2.27), the proportion of collisionless particles is

$\boldsymbol {W}^h_i$ at all. According to the cumulative distribution (2.27), the proportion of collisionless particles is ![]() $\exp {(-\Delta t/\tau )}$, and therefore, in UGKWP, only the collisionless particles from the hydrodynamic variables

$\exp {(-\Delta t/\tau )}$, and therefore, in UGKWP, only the collisionless particles from the hydrodynamic variables ![]() $\boldsymbol {W}^{h}_i$ in cell

$\boldsymbol {W}^{h}_i$ in cell ![]() $i$ will be re-sampled with the total mass, momentum and energy

$i$ will be re-sampled with the total mass, momentum and energy

Then, the free transport time of all these re-sampled particles will be given by ![]() $t_f=\Delta t$ in UGKWP. The fluxes

$t_f=\Delta t$ in UGKWP. The fluxes ![]() $\boldsymbol {F}^{fr,wave}$ from these un-sampled collisional particles from

$\boldsymbol {F}^{fr,wave}$ from these un-sampled collisional particles from ![]() $(1- \exp {(-\Delta t/\tau )} )\boldsymbol {W}^{h}_i$ can be evaluated analytically (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu et al. Reference Liu, Zhu and Xu2020). Now, the same as UGKP, in UGKWP, the net flux

$(1- \exp {(-\Delta t/\tau )} )\boldsymbol {W}^{h}_i$ can be evaluated analytically (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu et al. Reference Liu, Zhu and Xu2020). Now, the same as UGKP, in UGKWP, the net flux ![]() $\boldsymbol {w}_{i}^{fr,p}$ by the free streaming of the particles, which include remaining particles from the previous time step and re-sampled collisionless ones, can be calculated by

$\boldsymbol {w}_{i}^{fr,p}$ by the free streaming of the particles, which include remaining particles from the previous time step and re-sampled collisionless ones, can be calculated by

So, the macroscopic flow variables in UGKWP are updated by

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{eq}_{ij}S_{ij} - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{fr,wave}_{ij}S_{ij} + \frac{\boldsymbol{w}_{i}^{fr,p}}{\varOmega_{i}} + \boldsymbol{S}_{i} \Delta t, \end{equation}

\begin{equation} \boldsymbol{W}_i^{*} = \boldsymbol{W}_i^n - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{eq}_{ij}S_{ij} - \frac{1}{\varOmega_i} \sum_{S_{ij}\in \partial \varOmega_i}\boldsymbol{F}^{fr,wave}_{ij}S_{ij} + \frac{\boldsymbol{w}_{i}^{fr,p}}{\varOmega_{i}} + \boldsymbol{S}_{i} \Delta t, \end{equation}

where ![]() $\boldsymbol {F}^{fr,wave}_{ij}$ is the flux function from the un-sampled collisional particles (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu et al. Reference Liu, Zhu and Xu2020)

$\boldsymbol {F}^{fr,wave}_{ij}$ is the flux function from the un-sampled collisional particles (Zhu et al. Reference Zhu, Liu, Zhong and Xu2019b; Liu et al. Reference Liu, Zhu and Xu2020)

\begin{align} \boldsymbol{F}^{fr,wave}_{ij} &=\boldsymbol{F}^{fr,UGKS}_{ij}(\boldsymbol{W}^h_i) - \boldsymbol{F}^{fr,DVM}_{ij}(\boldsymbol{W}^{hp}_i)\nonumber\\ &=\int_{0}^{\Delta t} \int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} [ {\rm e}^{{-}t/\tau}f_0(\boldsymbol{x}-\boldsymbol{u}t,\boldsymbol{u})] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\quad -{\rm e}^{-\Delta t/\tau}\int_{0}^{\Delta t} \int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} [g_0^h(\boldsymbol{x},\boldsymbol{u}) - t\boldsymbol{u} \boldsymbol{\cdot} g_{\boldsymbol{x}}^h(\boldsymbol{x},\boldsymbol{u})] \boldsymbol{\psi}\,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &=\int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} \left[ (q_4 - \Delta t \,{\rm e}^{-\Delta t/\tau}) g_0^h (\boldsymbol{x},\boldsymbol{u}) + \left(q_5 + \frac{\Delta t^2}{2}\,{\rm e}^{-\Delta t/\tau}\right) \boldsymbol{u} \boldsymbol{\cdot} g_{\boldsymbol{x}}^h(\boldsymbol{x},\boldsymbol{u}) \right]\boldsymbol{\psi}\,\text{d}\boldsymbol{u}, \end{align}

\begin{align} \boldsymbol{F}^{fr,wave}_{ij} &=\boldsymbol{F}^{fr,UGKS}_{ij}(\boldsymbol{W}^h_i) - \boldsymbol{F}^{fr,DVM}_{ij}(\boldsymbol{W}^{hp}_i)\nonumber\\ &=\int_{0}^{\Delta t} \int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} [ {\rm e}^{{-}t/\tau}f_0(\boldsymbol{x}-\boldsymbol{u}t,\boldsymbol{u})] \boldsymbol{\psi} \,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &\quad -{\rm e}^{-\Delta t/\tau}\int_{0}^{\Delta t} \int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} [g_0^h(\boldsymbol{x},\boldsymbol{u}) - t\boldsymbol{u} \boldsymbol{\cdot} g_{\boldsymbol{x}}^h(\boldsymbol{x},\boldsymbol{u})] \boldsymbol{\psi}\,\text{d}\boldsymbol{u}\,\text{d}t\nonumber\\ &=\int \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n}_{ij} \left[ (q_4 - \Delta t \,{\rm e}^{-\Delta t/\tau}) g_0^h (\boldsymbol{x},\boldsymbol{u}) + \left(q_5 + \frac{\Delta t^2}{2}\,{\rm e}^{-\Delta t/\tau}\right) \boldsymbol{u} \boldsymbol{\cdot} g_{\boldsymbol{x}}^h(\boldsymbol{x},\boldsymbol{u}) \right]\boldsymbol{\psi}\,\text{d}\boldsymbol{u}, \end{align}with

In the second part ![]() $\mathcal {L}_{d2}$,

$\mathcal {L}_{d2}$, ![]() $\boldsymbol {W}^{*}\to \boldsymbol {W}^{**}$ models the effect of cross-species collision between solid particles in different disperse phases. Taking the

$\boldsymbol {W}^{*}\to \boldsymbol {W}^{**}$ models the effect of cross-species collision between solid particles in different disperse phases. Taking the ![]() $k$th disperse phase for example, its collision with other disperse phases can be evaluated by

$k$th disperse phase for example, its collision with other disperse phases can be evaluated by

\begin{equation} \frac{\partial f_{k}}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}. \end{equation}

\begin{equation} \frac{\partial f_{k}}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{g_{ik}-f_{k}}{\tau_{ik}}. \end{equation}

Obviously, ![]() $\epsilon _{k}^{**}=\epsilon _k^{*}$ with the above formula of

$\epsilon _{k}^{**}=\epsilon _k^{*}$ with the above formula of ![]() $g_{ik}$. Taking moment

$g_{ik}$. Taking moment ![]() $\boldsymbol {\psi }=\boldsymbol {u}$ in the Euler regime with

$\boldsymbol {\psi }=\boldsymbol {u}$ in the Euler regime with ![]() $f_k = g_k + {O}(\tau _{k})$, we can obtain

$f_k = g_k + {O}(\tau _{k})$, we can obtain

\begin{equation} \frac{\partial ( \epsilon_{k}\rho_k\boldsymbol{U}_k )}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{\epsilon_k\rho_k(\boldsymbol{U}_{ik}-\boldsymbol{U}_k)}{\tau_{ik}}. \end{equation}

\begin{equation} \frac{\partial ( \epsilon_{k}\rho_k\boldsymbol{U}_k )}{\partial t} = \sum_{i=1,i\neq k}^{N} \frac{\epsilon_k\rho_k(\boldsymbol{U}_{ik}-\boldsymbol{U}_k)}{\tau_{ik}}. \end{equation}

In this paper, the auxiliary velocity between the ![]() $i$th and

$i$th and ![]() $k$th disperse phase,

$k$th disperse phase, ![]() $\boldsymbol {U}_{ik}$, is assumed as

$\boldsymbol {U}_{ik}$, is assumed as

Now, we need to determine ![]() $\tau _{ik}$, i.e. the collision time between the

$\tau _{ik}$, i.e. the collision time between the ![]() $i$th and

$i$th and ![]() $k$th disperse phase. Generally, the commonly employed parameter in the polydisperse particular flow is

$k$th disperse phase. Generally, the commonly employed parameter in the polydisperse particular flow is ![]() $\beta _{ik}$, which is named the so-called inter-solid drag model and has the following relationship with

$\beta _{ik}$, which is named the so-called inter-solid drag model and has the following relationship with ![]() $\tau _{ik}$:

$\tau _{ik}$:

Substituting (2.40) into (2.41), the expression of ![]() $\tau _{ik}$ can be explicitly obtained

$\tau _{ik}$ can be explicitly obtained

and the closure of ![]() $\beta _{ik}$ will be introduced in the following. Here,

$\beta _{ik}$ will be introduced in the following. Here, ![]() $\boldsymbol {U}^{**}_k$ can be obtained by the analytical solution

$\boldsymbol {U}^{**}_k$ can be obtained by the analytical solution

The parameter ![]() $\beta _{ik}$ reflects the momentum and energy exchanges between different disperse solid phases, which play an important role in polydisperse solid particle flow. Many studies have been conducted about

$\beta _{ik}$ reflects the momentum and energy exchanges between different disperse solid phases, which play an important role in polydisperse solid particle flow. Many studies have been conducted about ![]() $\beta _{ik}$ (Syamlal Reference Syamlal1987; Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999; Fan & Fox Reference Fan and Fox2008). In this paper, the inter-solid drag model proposed by Mathiesen based on kinetic theory of granular flow (KTGF) will be used (Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999)

$\beta _{ik}$ (Syamlal Reference Syamlal1987; Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999; Fan & Fox Reference Fan and Fox2008). In this paper, the inter-solid drag model proposed by Mathiesen based on kinetic theory of granular flow (KTGF) will be used (Mathiesen et al. Reference Mathiesen, Solberg, Arastoopour and Hjertager1999)

\begin{align} \beta_{ik} & = \frac{3 p_{c,ik}}{d_{ik}} \left[ \frac{2(m_k^2\theta_k + m_i^2\theta_i)}{{\rm \pi} m_0^2 \theta_k\theta_i} \right]^{1/2}\nonumber\\ &\quad +\frac{p_{c,ik}}{|\boldsymbol{U}_k - \boldsymbol{U}_i|} \left[ \boldsymbol{\nabla}_x \ln \frac{\epsilon_{k}}{\epsilon_{i}} + 3 \boldsymbol{\nabla}_x \frac{\ln (m_i\theta_i)}{\ln (m_k\theta_k)} + \frac{\theta_k\theta_i}{\theta_k+\theta_i} \left( \frac{\boldsymbol{\nabla}_x \theta_k}{\theta_k^2} - \frac{\boldsymbol{\nabla}_x \theta_i}{\theta_i^2}\right) \right], \end{align}

\begin{align} \beta_{ik} & = \frac{3 p_{c,ik}}{d_{ik}} \left[ \frac{2(m_k^2\theta_k + m_i^2\theta_i)}{{\rm \pi} m_0^2 \theta_k\theta_i} \right]^{1/2}\nonumber\\ &\quad +\frac{p_{c,ik}}{|\boldsymbol{U}_k - \boldsymbol{U}_i|} \left[ \boldsymbol{\nabla}_x \ln \frac{\epsilon_{k}}{\epsilon_{i}} + 3 \boldsymbol{\nabla}_x \frac{\ln (m_i\theta_i)}{\ln (m_k\theta_k)} + \frac{\theta_k\theta_i}{\theta_k+\theta_i} \left( \frac{\boldsymbol{\nabla}_x \theta_k}{\theta_k^2} - \frac{\boldsymbol{\nabla}_x \theta_i}{\theta_i^2}\right) \right], \end{align}

where ![]() $p_{c,ik}$ is the collisional pressure between the

$p_{c,ik}$ is the collisional pressure between the ![]() $i$th and

$i$th and ![]() $k$th disperse phase

$k$th disperse phase

\begin{equation} p_{c,ik} = \frac{{\rm \pi}(1+e_{ik})d_{ik}^3g_{ik}\epsilon_i\rho_i\epsilon_k\rho_k \theta_i\theta_k(m_i+m_k)}{3(m_i^2\theta_i+m_k^2\theta_k)} \left[\frac{(m_i+m_k)^2\theta_i\theta_k}{(m_i^2\theta_i+m_k^2\theta_k) (\theta_i+\theta_k)}\right]^{3/2}, \end{equation}

\begin{equation} p_{c,ik} = \frac{{\rm \pi}(1+e_{ik})d_{ik}^3g_{ik}\epsilon_i\rho_i\epsilon_k\rho_k \theta_i\theta_k(m_i+m_k)}{3(m_i^2\theta_i+m_k^2\theta_k)} \left[\frac{(m_i+m_k)^2\theta_i\theta_k}{(m_i^2\theta_i+m_k^2\theta_k) (\theta_i+\theta_k)}\right]^{3/2}, \end{equation}with

In this paper, we take ![]() $\theta _k^{**}=\theta _k^{*}$, which means that the effect on the granular temperature from intensive particles’ collisions is neglected due to the low value of the granular temperature in the inelastic particles’ collision (Fox & Vedula Reference Fox and Vedula2010). Note that this effect can be further considered by taking moment

$\theta _k^{**}=\theta _k^{*}$, which means that the effect on the granular temperature from intensive particles’ collisions is neglected due to the low value of the granular temperature in the inelastic particles’ collision (Fox & Vedula Reference Fox and Vedula2010). Note that this effect can be further considered by taking moment ![]() $\boldsymbol {\psi }={\boldsymbol {u}^2}/{2}$ on

$\boldsymbol {\psi }={\boldsymbol {u}^2}/{2}$ on ![]() $\mathcal {L}_{d2}$.

$\mathcal {L}_{d2}$.

Finally, in the third part ![]() $\mathcal {L}_{d3}$,

$\mathcal {L}_{d3}$, ![]() $\boldsymbol {W}^{**}\to \boldsymbol {W}^{n+1}$ accounts for the acceleration

$\boldsymbol {W}^{**}\to \boldsymbol {W}^{n+1}$ accounts for the acceleration

where the acceleration of one solid particle ![]() $\boldsymbol {a}$ can be decomposed into three parts

$\boldsymbol {a}$ can be decomposed into three parts

where ![]() $\boldsymbol {a}_D$ is the velocity-dependent drag force from the gas–solid interaction

$\boldsymbol {a}_D$ is the velocity-dependent drag force from the gas–solid interaction

where ![]() $\boldsymbol {a}_c$ is the velocity-independent buoyancy and gravitational force on the solid particle

$\boldsymbol {a}_c$ is the velocity-independent buoyancy and gravitational force on the solid particle

and ![]() $\boldsymbol {a}_p$ is the force from the collisional and frictional pressure among solid phases. As shown later,

$\boldsymbol {a}_p$ is the force from the collisional and frictional pressure among solid phases. As shown later, ![]() $\boldsymbol {a}_p$ mainly contributes in dense particle flow and is similar to a normal stress. It is conditionally updated in the MP-PIC method (Snider Reference Snider2001, Reference Snider2007; Verma & Padding Reference Verma and Padding2020).

$\boldsymbol {a}_p$ mainly contributes in dense particle flow and is similar to a normal stress. It is conditionally updated in the MP-PIC method (Snider Reference Snider2001, Reference Snider2007; Verma & Padding Reference Verma and Padding2020).

Taking moment ![]() $\boldsymbol {\psi }$ on the equation of

$\boldsymbol {\psi }$ on the equation of ![]() $\mathcal {L}_{d3}$, in the Euler regime with

$\mathcal {L}_{d3}$, in the Euler regime with ![]() $f_k = g_k + {O}(\tau _{k})$, we get

$f_k = g_k + {O}(\tau _{k})$, we get

where

\begin{equation}

\boldsymbol{Q}_k=\left[\begin{array}{@{}c@{}} 0 \\ \dfrac{

\epsilon_k\rho_k (\boldsymbol{U}_g -

\boldsymbol{U}_k)}{\tau_{st,k}} + \epsilon_{k}\rho_{k}

(\boldsymbol{a}_c + \boldsymbol{a}_p) \\

\dfrac{\epsilon_k\rho_{k}\boldsymbol{U}_k

\boldsymbol{\cdot}

(\boldsymbol{U}_g-\boldsymbol{U}_k)}{\tau_{st,k}} -

3\dfrac{\epsilon_k\rho_{k}\theta_k}{\tau_{st,k}} +

\epsilon_{k}\rho_{k} \boldsymbol{U}_k \boldsymbol{\cdot}

(\boldsymbol{a}_c + \boldsymbol{a}_p) \end{array}\right].

\end{equation}

\begin{equation}

\boldsymbol{Q}_k=\left[\begin{array}{@{}c@{}} 0 \\ \dfrac{

\epsilon_k\rho_k (\boldsymbol{U}_g -

\boldsymbol{U}_k)}{\tau_{st,k}} + \epsilon_{k}\rho_{k}

(\boldsymbol{a}_c + \boldsymbol{a}_p) \\

\dfrac{\epsilon_k\rho_{k}\boldsymbol{U}_k

\boldsymbol{\cdot}

(\boldsymbol{U}_g-\boldsymbol{U}_k)}{\tau_{st,k}} -

3\dfrac{\epsilon_k\rho_{k}\theta_k}{\tau_{st,k}} +

\epsilon_{k}\rho_{k} \boldsymbol{U}_k \boldsymbol{\cdot}

(\boldsymbol{a}_c + \boldsymbol{a}_p) \end{array}\right].

\end{equation}

Here, (2.52) will be updated in the following. Firstly, the gas–solid drag between the ![]() $k$th disperse phase and gas flow

$k$th disperse phase and gas flow

\begin{equation} \left.\begin{array}{c@{}} \dfrac{\partial (\epsilon_k\rho_k \boldsymbol{U}_k)}{\partial t} = \beta_k(\boldsymbol{U}_g-\boldsymbol{U}_k), \\ \dfrac{\partial (\tilde{\rho}_g \boldsymbol{U}_g)}{\partial t} ={-}\beta_k(\boldsymbol{U}_g-\boldsymbol{U}_k), \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}} \dfrac{\partial (\epsilon_k\rho_k \boldsymbol{U}_k)}{\partial t} = \beta_k(\boldsymbol{U}_g-\boldsymbol{U}_k), \\ \dfrac{\partial (\tilde{\rho}_g \boldsymbol{U}_g)}{\partial t} ={-}\beta_k(\boldsymbol{U}_g-\boldsymbol{U}_k), \end{array}\right\} \end{equation}is discretized implicitly

\begin{equation} \left.\begin{array}{c@{}}

\dfrac{\epsilon_k^{n+1}\rho_k \boldsymbol{U}_k^{***} -

\epsilon_k^{**}\rho_k \boldsymbol{U}_k^{**}}{\Delta t_s} =

\beta_k^{**}(\boldsymbol{U}_g^{***}-\boldsymbol{U}_k^{***}),\\

\dfrac{\tilde{\rho}_g^{n+1} \boldsymbol{U}_g^{***} -

\tilde{\rho}_g^{**} \boldsymbol{U}_g^{**}}{\Delta t_s}

={-}\beta_k^{**}(\boldsymbol{U}_g^{***}-\boldsymbol{U}_k^{***}),

\end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}}

\dfrac{\epsilon_k^{n+1}\rho_k \boldsymbol{U}_k^{***} -

\epsilon_k^{**}\rho_k \boldsymbol{U}_k^{**}}{\Delta t_s} =

\beta_k^{**}(\boldsymbol{U}_g^{***}-\boldsymbol{U}_k^{***}),\\

\dfrac{\tilde{\rho}_g^{n+1} \boldsymbol{U}_g^{***} -

\tilde{\rho}_g^{**} \boldsymbol{U}_g^{**}}{\Delta t_s}

={-}\beta_k^{**}(\boldsymbol{U}_g^{***}-\boldsymbol{U}_k^{***}),

\end{array}\right\} \end{equation}

where ![]() $\beta _k = {\epsilon _{k}\rho _{k}}/{\tau _{st,k}}$ is determined based on the drag model of the

$\beta _k = {\epsilon _{k}\rho _{k}}/{\tau _{st,k}}$ is determined based on the drag model of the ![]() $k$th disperse phase. Obviously, we have

$k$th disperse phase. Obviously, we have ![]() $\epsilon _k^{n+1} = \epsilon _k^{**}$,

$\epsilon _k^{n+1} = \epsilon _k^{**}$, ![]() $\tilde {\rho }_g^{n+1}=\tilde {\rho }_g^{**}$, and thus we get

$\tilde {\rho }_g^{n+1}=\tilde {\rho }_g^{**}$, and thus we get

\begin{equation} \left.\begin{array}{c@{}}

\boldsymbol{U}_k^{***} = \dfrac{\boldsymbol{U}_g^{**}

\Delta t_s + \boldsymbol{U}_k^{**} r \Delta t_s +

\boldsymbol{U}_k^{**} \tau_{st,k}}{\Delta t_s + r \Delta

t_s + \tau_{st,k}},\\ \boldsymbol{U}_g^{***} =

\dfrac{\boldsymbol{U}_g^{**} \Delta t_s +

\boldsymbol{U}_k^{**} r \Delta t_s + \boldsymbol{U}_g^{**}

\tau_{st,k}}{\Delta t_s + r \Delta t_s + \tau_{st,k}},

\end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}}

\boldsymbol{U}_k^{***} = \dfrac{\boldsymbol{U}_g^{**}

\Delta t_s + \boldsymbol{U}_k^{**} r \Delta t_s +

\boldsymbol{U}_k^{**} \tau_{st,k}}{\Delta t_s + r \Delta

t_s + \tau_{st,k}},\\ \boldsymbol{U}_g^{***} =

\dfrac{\boldsymbol{U}_g^{**} \Delta t_s +

\boldsymbol{U}_k^{**} r \Delta t_s + \boldsymbol{U}_g^{**}

\tau_{st,k}}{\Delta t_s + r \Delta t_s + \tau_{st,k}},

\end{array}\right\} \end{equation}

with ![]() $r={\epsilon _k^{**}\rho _k}/{\tilde {\rho }_g^{**}}$. Then, the particle's acceleration due to drag can be written as

$r={\epsilon _k^{**}\rho _k}/{\tilde {\rho }_g^{**}}$. Then, the particle's acceleration due to drag can be written as

and the acceleration without ![]() $\boldsymbol {a}_p$ can be expressed as

$\boldsymbol {a}_p$ can be expressed as

Then, the macroscopic variables of the ![]() $k$th solid phase are updated by

$k$th solid phase are updated by

\begin{equation} \left.\begin{array}{l} \epsilon_{k}^{n+1}\rho_k\boldsymbol{U}_k^{***} = \epsilon_{k}^{**}\rho_k\boldsymbol{U}_k^{**} + \epsilon_{k}^{**}\rho_k \boldsymbol{a}^{***} \Delta t_s,\\ \epsilon_{k}^{n+1}\rho_kE_k^{***} = \epsilon_{k}^{**}\rho_kE_k^{**} + \left( \epsilon_{k}^{**}\rho_k \boldsymbol{U}_k^{**} \boldsymbol{\cdot} \boldsymbol{a}^{***} - 3\dfrac{\epsilon_k^{**}\rho_{k}\theta_k^{**}}{\tau_{st,k}} \right)\Delta t_s, \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{l} \epsilon_{k}^{n+1}\rho_k\boldsymbol{U}_k^{***} = \epsilon_{k}^{**}\rho_k\boldsymbol{U}_k^{**} + \epsilon_{k}^{**}\rho_k \boldsymbol{a}^{***} \Delta t_s,\\ \epsilon_{k}^{n+1}\rho_kE_k^{***} = \epsilon_{k}^{**}\rho_kE_k^{**} + \left( \epsilon_{k}^{**}\rho_k \boldsymbol{U}_k^{**} \boldsymbol{\cdot} \boldsymbol{a}^{***} - 3\dfrac{\epsilon_k^{**}\rho_{k}\theta_k^{**}}{\tau_{st,k}} \right)\Delta t_s, \end{array}\right\} \end{equation}

where ![]() $\epsilon _{k}^{n+1} \rho _k E_k^{***} = \frac {1}{2}\epsilon _{k}^{n+1}\rho _k \boldsymbol {U}_k^2 + \frac {3}{2}\epsilon _{k}^{n+1}\rho _k\theta _k^{***}$.

$\epsilon _{k}^{n+1} \rho _k E_k^{***} = \frac {1}{2}\epsilon _{k}^{n+1}\rho _k \boldsymbol {U}_k^2 + \frac {3}{2}\epsilon _{k}^{n+1}\rho _k\theta _k^{***}$.

As in the treatment of MP-PIC method, ![]() $\boldsymbol {a}_p$ is updated at the end as (Snider Reference Snider2001, Reference Snider2007)

$\boldsymbol {a}_p$ is updated at the end as (Snider Reference Snider2001, Reference Snider2007)

where ![]() $p_{k,c}$ and

$p_{k,c}$ and ![]() $p_{k,f}$ are the collisional pressure and frictional pressure of the

$p_{k,f}$ are the collisional pressure and frictional pressure of the ![]() $k$th disperse phase, which are determined by (2.70) and (2.71), respectively. In this paper, the

$k$th disperse phase, which are determined by (2.70) and (2.71), respectively. In this paper, the ![]() $\boldsymbol {a}_p$ obtained by (2.60) is further constrained by the following stability conditions:

$\boldsymbol {a}_p$ obtained by (2.60) is further constrained by the following stability conditions:

\begin{equation}

\left.\begin{array}{c@{}}

| \tfrac{1}{2} \boldsymbol{a}_p \Delta t_s^2 | \le k_c \Delta_{cell} ,\\

|\boldsymbol{U}^{***}_k\Delta t_s + \tfrac{1}{2} \boldsymbol{a}_p \Delta t_s^2 | \le k_c

\varDelta_{cell}, \end{array}\right\}

\end{equation}

\begin{equation}

\left.\begin{array}{c@{}}

| \tfrac{1}{2} \boldsymbol{a}_p \Delta t_s^2 | \le k_c \Delta_{cell} ,\\

|\boldsymbol{U}^{***}_k\Delta t_s + \tfrac{1}{2} \boldsymbol{a}_p \Delta t_s^2 | \le k_c

\varDelta_{cell}, \end{array}\right\}

\end{equation}

where ![]() $\varDelta _{cell}$ is the cell size and

$\varDelta _{cell}$ is the cell size and ![]() $k_c$ is a safety factor with a value smaller than 1, such as

$k_c$ is a safety factor with a value smaller than 1, such as ![]() $0.8$, as used in this paper. Now the acceleration can be fully determined as

$0.8$, as used in this paper. Now the acceleration can be fully determined as

The macroscopic velocity of the ![]() $k$th solid phase

$k$th solid phase ![]() $\boldsymbol {U}_k^{n+1}$ is updated by

$\boldsymbol {U}_k^{n+1}$ is updated by

with the granular temperature ![]() $\theta _k^{n+1}=\theta _k^{***}$.

$\theta _k^{n+1}=\theta _k^{***}$.

Besides, the velocity and location of the remaining free transport particles are updated as

The above procedures are used to update the disperse particle phase in one time step ![]() $\Delta t_s$.

$\Delta t_s$.

2.3. The  $\textrm {Kn}$ and flow regime of the solid particle phase

$\textrm {Kn}$ and flow regime of the solid particle phase

The parameter ![]() $\textrm {Kn}_k$ stands for the Knudsen number of the

$\textrm {Kn}_k$ stands for the Knudsen number of the ![]() $k$th disperse particle phase, and it is defined by the ratio of the collision time

$k$th disperse particle phase, and it is defined by the ratio of the collision time ![]() $\tau _{k}$ to the characteristic time scale of macroscopic flow

$\tau _{k}$ to the characteristic time scale of macroscopic flow ![]() $t_{ref}$

$t_{ref}$

The characteristic time ![]() $t_{ref}$ takes the time step of the solid phase

$t_{ref}$ takes the time step of the solid phase ![]() $\Delta t_s$ and

$\Delta t_s$ and ![]() $\tau _k$ is the time interval between collisions of solid particles. In this paper,

$\tau _k$ is the time interval between collisions of solid particles. In this paper, ![]() $\tau _k$ is defined as (Passalacqua et al. Reference Passalacqua, Fox, Garg and Subramaniam2010; Marchisio & Fox Reference Marchisio and Fox2013)

$\tau _k$ is defined as (Passalacqua et al. Reference Passalacqua, Fox, Garg and Subramaniam2010; Marchisio & Fox Reference Marchisio and Fox2013)

where ![]() $d_k$,

$d_k$, ![]() $\epsilon _k$ and

$\epsilon _k$ and ![]() $\theta _k$ are the diameter of the solid particle, volume fraction and the granular temperature of the

$\theta _k$ are the diameter of the solid particle, volume fraction and the granular temperature of the ![]() $k$th disperse phase. Here,

$k$th disperse phase. Here, ![]() $g_0$ is the radial distribution function with the following form:

$g_0$ is the radial distribution function with the following form:

where ![]() $c=\epsilon _t/\epsilon _{s,max}$ is the ratio of the total solid volume fraction

$c=\epsilon _t/\epsilon _{s,max}$ is the ratio of the total solid volume fraction ![]() $\epsilon _{t}$ to the allowed maximum value

$\epsilon _{t}$ to the allowed maximum value ![]() $\epsilon _{s,max}$ for the polydisperse solid mixture. The flow regime of the

$\epsilon _{s,max}$ for the polydisperse solid mixture. The flow regime of the ![]() $k$th disperse phase is determined by

$k$th disperse phase is determined by ![]() $\textrm {Kn}_k$. Generally, for the dilute flow, the collision frequency between solid particles is low, leading to a large

$\textrm {Kn}_k$. Generally, for the dilute flow, the collision frequency between solid particles is low, leading to a large ![]() $\textrm {Kn}_k$, and UGKWP will sample and track the solid particles, keeping the non-equilibrium automatically. On the contrary, in the high concentration region, the high collision frequency between particles means the solid phase is in the equilibrium state, and no particles will be sampled in UGKWP. In the limit of the continuum flow regime with

$\textrm {Kn}_k$, and UGKWP will sample and track the solid particles, keeping the non-equilibrium automatically. On the contrary, in the high concentration region, the high collision frequency between particles means the solid phase is in the equilibrium state, and no particles will be sampled in UGKWP. In the limit of the continuum flow regime with ![]() $e=1$, the above UGKWP method for (2.1) can recover the solution of the following hydrodynamic equations:

$e=1$, the above UGKWP method for (2.1) can recover the solution of the following hydrodynamic equations:

\begin{align} &\frac{\partial (\epsilon_k\rho_k \boldsymbol{U}_k)}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} (\epsilon_k\rho_k \boldsymbol{U}_k \boldsymbol{U}_k + p_k \mathbb{I} ) = \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st,k}} \nonumber\\ &\quad - \epsilon_{k} \boldsymbol{\nabla}_{\boldsymbol{x}} p_g + \epsilon_{k}\rho_{k} \boldsymbol{G} + \sum_{i=1,i\neq k}^{N} \beta_{ik}(\boldsymbol{U}_{i}-\boldsymbol{U}_{k}) , \end{align}

\begin{align} &\frac{\partial (\epsilon_k\rho_k \boldsymbol{U}_k)}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} (\epsilon_k\rho_k \boldsymbol{U}_k \boldsymbol{U}_k + p_k \mathbb{I} ) = \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st,k}} \nonumber\\ &\quad - \epsilon_{k} \boldsymbol{\nabla}_{\boldsymbol{x}} p_g + \epsilon_{k}\rho_{k} \boldsymbol{G} + \sum_{i=1,i\neq k}^{N} \beta_{ik}(\boldsymbol{U}_{i}-\boldsymbol{U}_{k}) , \end{align} \begin{align} &\frac{\partial (\epsilon_k\rho_k E_k)}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} ((\epsilon_k\rho_k E_k + p_{k}) \boldsymbol{U}_k ) = \frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st,k}} \nonumber\\ &\quad - 3\frac{\epsilon_k\rho_k\theta_k}{\tau_{st,k}} - \epsilon_{k} \boldsymbol{U}_k \boldsymbol{\cdot} \boldsymbol{\nabla}_{\boldsymbol{x}} p_g + \epsilon_{k}\rho_{k} \boldsymbol{U}_k \boldsymbol{\cdot} \boldsymbol{G}. \end{align}

\begin{align} &\frac{\partial (\epsilon_k\rho_k E_k)}{\partial t} + \boldsymbol{\nabla}_{\boldsymbol{x}} \boldsymbol{\cdot} ((\epsilon_k\rho_k E_k + p_{k}) \boldsymbol{U}_k ) = \frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st,k}} \nonumber\\ &\quad - 3\frac{\epsilon_k\rho_k\theta_k}{\tau_{st,k}} - \epsilon_{k} \boldsymbol{U}_k \boldsymbol{\cdot} \boldsymbol{\nabla}_{\boldsymbol{x}} p_g + \epsilon_{k}\rho_{k} \boldsymbol{U}_k \boldsymbol{\cdot} \boldsymbol{G}. \end{align}

In (2.69), ![]() $p_k$ is the pressure of the

$p_k$ is the pressure of the ![]() $k$th disperse solid phase, and it is the sum of the kinetic pressure

$k$th disperse solid phase, and it is the sum of the kinetic pressure ![]() $p_{k,k} = \epsilon _k\rho _k\theta _k$, collisional pressure

$p_{k,k} = \epsilon _k\rho _k\theta _k$, collisional pressure ![]() $p_{c,k}$ and frictional pressure

$p_{c,k}$ and frictional pressure ![]() $p_{f,k}$. Lots of studies about

$p_{f,k}$. Lots of studies about ![]() $p_{c,k}$ and

$p_{c,k}$ and ![]() $p_{f,k}$ have been done, especially for the dense particular flow (Dou et al. Reference Dou, Wang, Ge and Ouyang2023). In this paper, the collisional pressure

$p_{f,k}$ have been done, especially for the dense particular flow (Dou et al. Reference Dou, Wang, Ge and Ouyang2023). In this paper, the collisional pressure ![]() $p_{c,k}$ is calculate by

$p_{c,k}$ is calculate by

\begin{equation} p_{c,k} = \sum_{i=1,i\neq k}^{N} p_{c,ik}, \end{equation}

\begin{equation} p_{c,k} = \sum_{i=1,i\neq k}^{N} p_{c,ik}, \end{equation}

where ![]() $p_{c,ik}$ is the collisional pressure between the

$p_{c,ik}$ is the collisional pressure between the ![]() $i$th and the

$i$th and the ![]() $k$th disperse phases, given in (2.45). The value of

$k$th disperse phases, given in (2.45). The value of ![]() $p_{f,k}$ accounts for the enduring inter-particle contacts and frictions of the

$p_{f,k}$ accounts for the enduring inter-particle contacts and frictions of the ![]() $k$th disperse phase, which play important roles when the solid phase is near packing. In this paper, the Johnson–Jackson model is employed (Johnson & Jackson Reference Johnson and Jackson1987; Houim & Oran Reference Houim and Oran2016)

$k$th disperse phase, which play important roles when the solid phase is near packing. In this paper, the Johnson–Jackson model is employed (Johnson & Jackson Reference Johnson and Jackson1987; Houim & Oran Reference Houim and Oran2016)

\begin{equation} p_{f,k} = \left\{\begin{array}{@{}ll} 0, & \epsilon_{t} \le \epsilon_{s,crit}, \\ 0.1 \epsilon_{k} \dfrac{(\epsilon_{t} - \epsilon_{s,crit})^2}{(\epsilon_{s,max} - \epsilon_{t})^5}, & \epsilon_{t} > \epsilon_{s,crit}. \end{array}\right. \end{equation}

\begin{equation} p_{f,k} = \left\{\begin{array}{@{}ll} 0, & \epsilon_{t} \le \epsilon_{s,crit}, \\ 0.1 \epsilon_{k} \dfrac{(\epsilon_{t} - \epsilon_{s,crit})^2}{(\epsilon_{s,max} - \epsilon_{t})^5}, & \epsilon_{t} > \epsilon_{s,crit}. \end{array}\right. \end{equation}

Here, ![]() $\epsilon _{s,crit}$ is the critical volume fraction of the whole solid phase. To avoid the solid volume fraction

$\epsilon _{s,crit}$ is the critical volume fraction of the whole solid phase. To avoid the solid volume fraction ![]() $\epsilon _{k}$ exceeding its maximum value

$\epsilon _{k}$ exceeding its maximum value ![]() $\epsilon _{s,max}$, i.e. the over-packing problem, the proposed flux limiting model near the packing condition is employed in the UGKWP method for the solid phase (Yang et al. Reference Yang, Shyy and Xu2022c).

$\epsilon _{s,max}$, i.e. the over-packing problem, the proposed flux limiting model near the packing condition is employed in the UGKWP method for the solid phase (Yang et al. Reference Yang, Shyy and Xu2022c).

3. Gas-kinetic scheme for gas phase

3.1. Governing equations for gas phase

The gas phase is regarded as the continuum flow and the governing equations are the NS equations with source terms reflecting the inter-phase interaction (Gidaspow Reference Gidaspow1994; Ishii & Hibiki Reference Ishii and Hibiki2006)

\begin{align} &\frac{\partial (\tilde{\rho}_g \boldsymbol{U}_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\tilde{\rho}_g \boldsymbol{U}_g \boldsymbol{U}_g + \widetilde{p_g}\mathbb{I}) - \epsilon_{g} \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\mu_g \boldsymbol{\sigma})\nonumber\\ &\quad = p_g \boldsymbol{\nabla}_x \epsilon_{g} -\sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st}} + \rho_g \boldsymbol{G}, \end{align}

\begin{align} &\frac{\partial (\tilde{\rho}_g \boldsymbol{U}_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\tilde{\rho}_g \boldsymbol{U}_g \boldsymbol{U}_g + \widetilde{p_g}\mathbb{I}) - \epsilon_{g} \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\mu_g \boldsymbol{\sigma})\nonumber\\ &\quad = p_g \boldsymbol{\nabla}_x \epsilon_{g} -\sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st}} + \rho_g \boldsymbol{G}, \end{align} \begin{align} &\frac{\partial (\tilde{\rho}_g E_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} ((\tilde{\rho}_g E_g + \widetilde{p_g}) \boldsymbol{U}_g ) - \epsilon_{g} \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\mu_g \boldsymbol{\sigma}\boldsymbol{\cdot}\boldsymbol{U}_g - \kappa \boldsymbol{\nabla}_x T_g ) \nonumber\\ &\quad ={-} p_{g} \frac{\partial \epsilon_{g}}{\partial t} - \sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st}} + \sum_{k=1}^{N}\frac{3\epsilon_k\rho_k\theta_k}{\tau_{st}} + \rho_g \boldsymbol{U}_g \boldsymbol{\cdot} \boldsymbol{G}, \end{align}

\begin{align} &\frac{\partial (\tilde{\rho}_g E_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} ((\tilde{\rho}_g E_g + \widetilde{p_g}) \boldsymbol{U}_g ) - \epsilon_{g} \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\mu_g \boldsymbol{\sigma}\boldsymbol{\cdot}\boldsymbol{U}_g - \kappa \boldsymbol{\nabla}_x T_g ) \nonumber\\ &\quad ={-} p_{g} \frac{\partial \epsilon_{g}}{\partial t} - \sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\tau_{st}} + \sum_{k=1}^{N}\frac{3\epsilon_k\rho_k\theta_k}{\tau_{st}} + \rho_g \boldsymbol{U}_g \boldsymbol{\cdot} \boldsymbol{G}, \end{align}

where ![]() $\tilde {\rho }_g=\epsilon _{g}\rho _g$ is the apparent density of the gas phase,

$\tilde {\rho }_g=\epsilon _{g}\rho _g$ is the apparent density of the gas phase, ![]() $p_g=\rho _gRT_g$ is the pressure of the gas phase and

$p_g=\rho _gRT_g$ is the pressure of the gas phase and ![]() $\widetilde {p_g}=\tilde {\rho }_gRT_g$. The strain rate tensor

$\widetilde {p_g}=\tilde {\rho }_gRT_g$. The strain rate tensor ![]() $\boldsymbol {\sigma }$ is

$\boldsymbol {\sigma }$ is

and

In particular, on the right-hand side of (3.1), the term ![]() $p_{g} \boldsymbol {\nabla }_x \epsilon _{g}$ is called the ‘nozzle’ term, and the associated work term

$p_{g} \boldsymbol {\nabla }_x \epsilon _{g}$ is called the ‘nozzle’ term, and the associated work term ![]() $- p_{g} ({\partial \epsilon _{g}}/{\partial t})$ is called the

$- p_{g} ({\partial \epsilon _{g}}/{\partial t})$ is called the ![]() $pDV$ work term, since it is similar to the

$pDV$ work term, since it is similar to the ![]() $pDV$ term in the quasi-one-dimensional gas nozzle flow equations (Houim & Oran Reference Houim and Oran2016). Unphysical pressure fluctuations might occur if the ‘nozzle’ term and

$pDV$ term in the quasi-one-dimensional gas nozzle flow equations (Houim & Oran Reference Houim and Oran2016). Unphysical pressure fluctuations might occur if the ‘nozzle’ term and ![]() $pDV$ term are not solved correctly. According to Toro (Reference Toro2013), (3.1) can be written as the following form:

$pDV$ term are not solved correctly. According to Toro (Reference Toro2013), (3.1) can be written as the following form:

\begin{align} &\frac{\partial (\rho_g \boldsymbol{U}_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\rho_g \boldsymbol{U}_g \boldsymbol{U}_g + p_g\mathbb{I} - \mu_g \boldsymbol{\sigma})\nonumber\\ &\quad = C_{\epsilon_g} \rho_g \boldsymbol{U}_g - \sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\epsilon_g \tau_{st}} + \frac{\rho_g\boldsymbol{G}}{\epsilon_{g}}, \end{align}

\begin{align} &\frac{\partial (\rho_g \boldsymbol{U}_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\rho_g \boldsymbol{U}_g \boldsymbol{U}_g + p_g\mathbb{I} - \mu_g \boldsymbol{\sigma})\nonumber\\ &\quad = C_{\epsilon_g} \rho_g \boldsymbol{U}_g - \sum_{k=1}^{N} \frac{\epsilon_{k}\rho_{k}(\boldsymbol{U}_g - \boldsymbol{U}_k)}{\epsilon_g \tau_{st}} + \frac{\rho_g\boldsymbol{G}}{\epsilon_{g}}, \end{align} \begin{align} &\frac{\partial (\rho_g E_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} ((\rho_g E_g + p_g) \boldsymbol{U}_g - \mu_g \boldsymbol{\sigma}\boldsymbol{\cdot}\boldsymbol{U}_g + \kappa \boldsymbol{\nabla}_x T_g) \nonumber\\ &\quad =C_{\epsilon_g} (\rho_g E_g + p_g) - \sum_{k=1}^{N}\frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\epsilon_g \tau_{st}} + \sum_{k=1}^{N}\frac{3\epsilon_k\rho_k\theta_k}{\epsilon_g \tau_{st}} + \frac{\rho_g \boldsymbol{U}_g \boldsymbol{\cdot} \boldsymbol{G}}{\epsilon_{g}}, \end{align}

\begin{align} &\frac{\partial (\rho_g E_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} ((\rho_g E_g + p_g) \boldsymbol{U}_g - \mu_g \boldsymbol{\sigma}\boldsymbol{\cdot}\boldsymbol{U}_g + \kappa \boldsymbol{\nabla}_x T_g) \nonumber\\ &\quad =C_{\epsilon_g} (\rho_g E_g + p_g) - \sum_{k=1}^{N}\frac{\epsilon_{k}\rho_{k}\boldsymbol{U}_k \boldsymbol{\cdot} (\boldsymbol{U}_g - \boldsymbol{U}_k)}{\epsilon_g \tau_{st}} + \sum_{k=1}^{N}\frac{3\epsilon_k\rho_k\theta_k}{\epsilon_g \tau_{st}} + \frac{\rho_g \boldsymbol{U}_g \boldsymbol{\cdot} \boldsymbol{G}}{\epsilon_{g}}, \end{align}

where ![]() $C_{\epsilon _g} = -({1}/{\epsilon _{g}})({\textrm {d}\epsilon _{g}}/{\textrm {d}t})$ with

$C_{\epsilon _g} = -({1}/{\epsilon _{g}})({\textrm {d}\epsilon _{g}}/{\textrm {d}t})$ with ![]() ${\textrm {d}\epsilon _{g}}/{\textrm {d}t}={\partial \epsilon _{g}}/{\partial t}+\boldsymbol {U}_g \boldsymbol {\cdot } \boldsymbol {\nabla }\epsilon _{g}$. The method to solve

${\textrm {d}\epsilon _{g}}/{\textrm {d}t}={\partial \epsilon _{g}}/{\partial t}+\boldsymbol {U}_g \boldsymbol {\cdot } \boldsymbol {\nabla }\epsilon _{g}$. The method to solve ![]() $C_{\epsilon _{g}}$ will be introduced later.

$C_{\epsilon _{g}}$ will be introduced later.

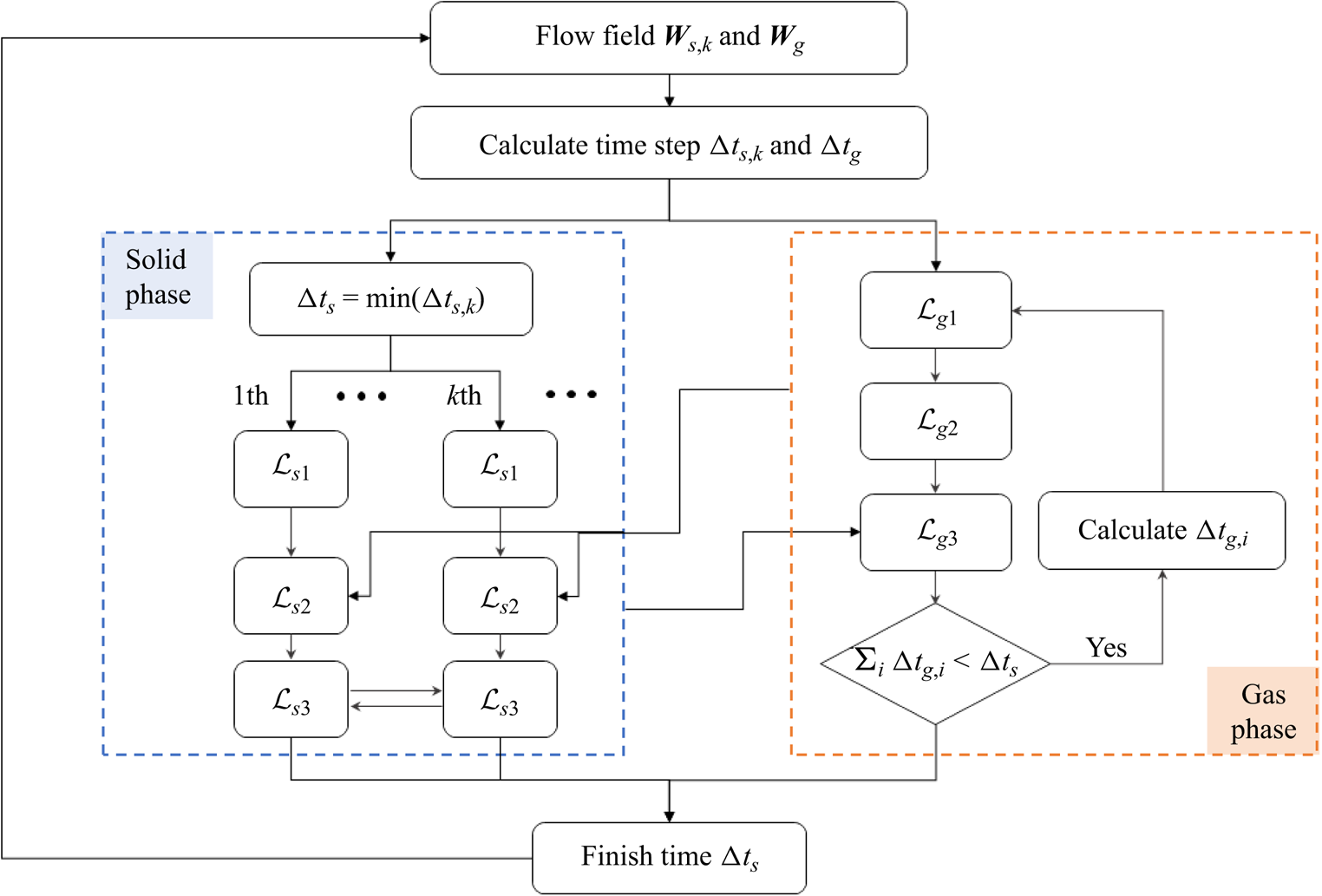

3.2. Gas-kinetic scheme for gas evolution

The gas flow is governed by the NS equations with the inter-phase interaction, and its solution will be obtained by the corresponding GKS, which is a limiting scheme of UGKWP in the continuum regime. In general, the evolution of the gas phase (3.4) in one time step ![]() $\Delta t_g$ can be split into three parts

$\Delta t_g$ can be split into three parts

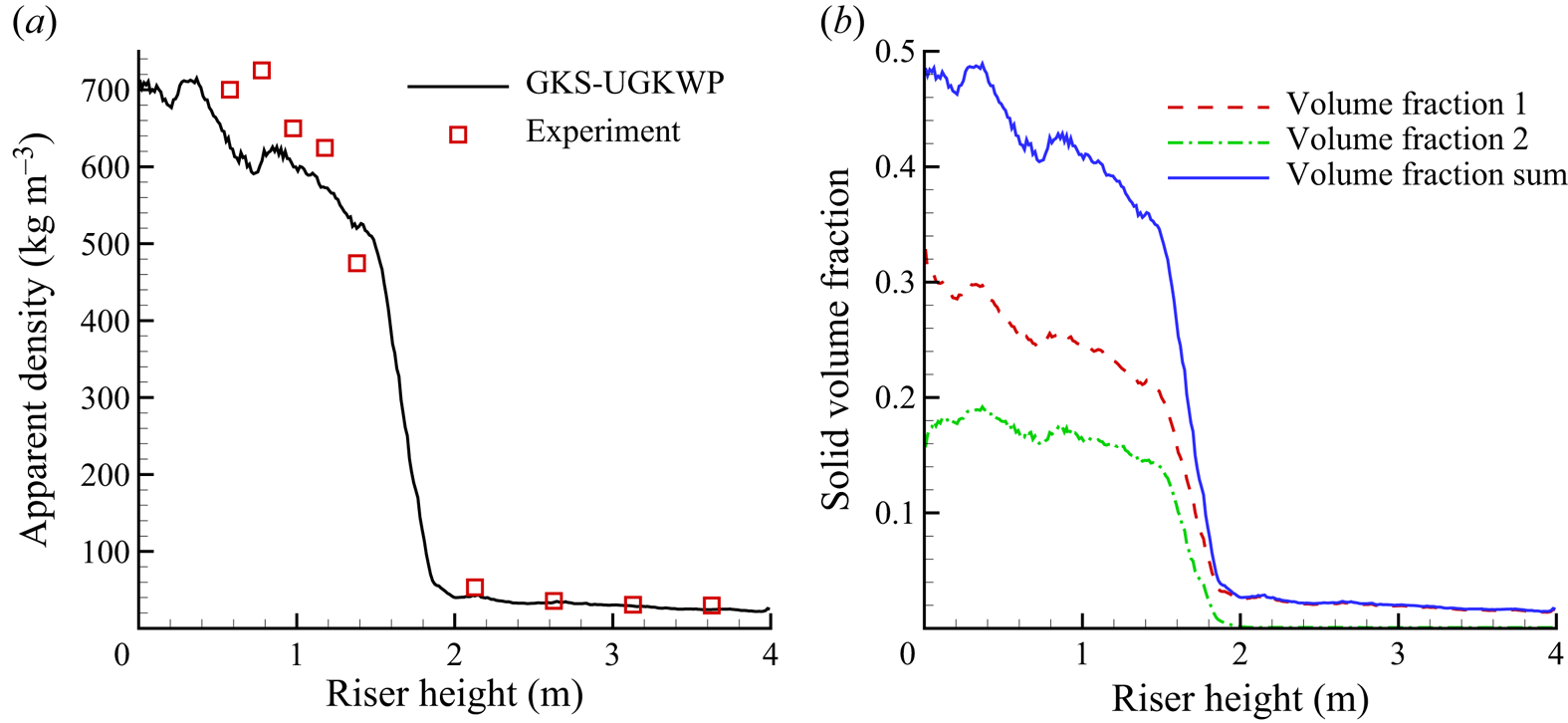

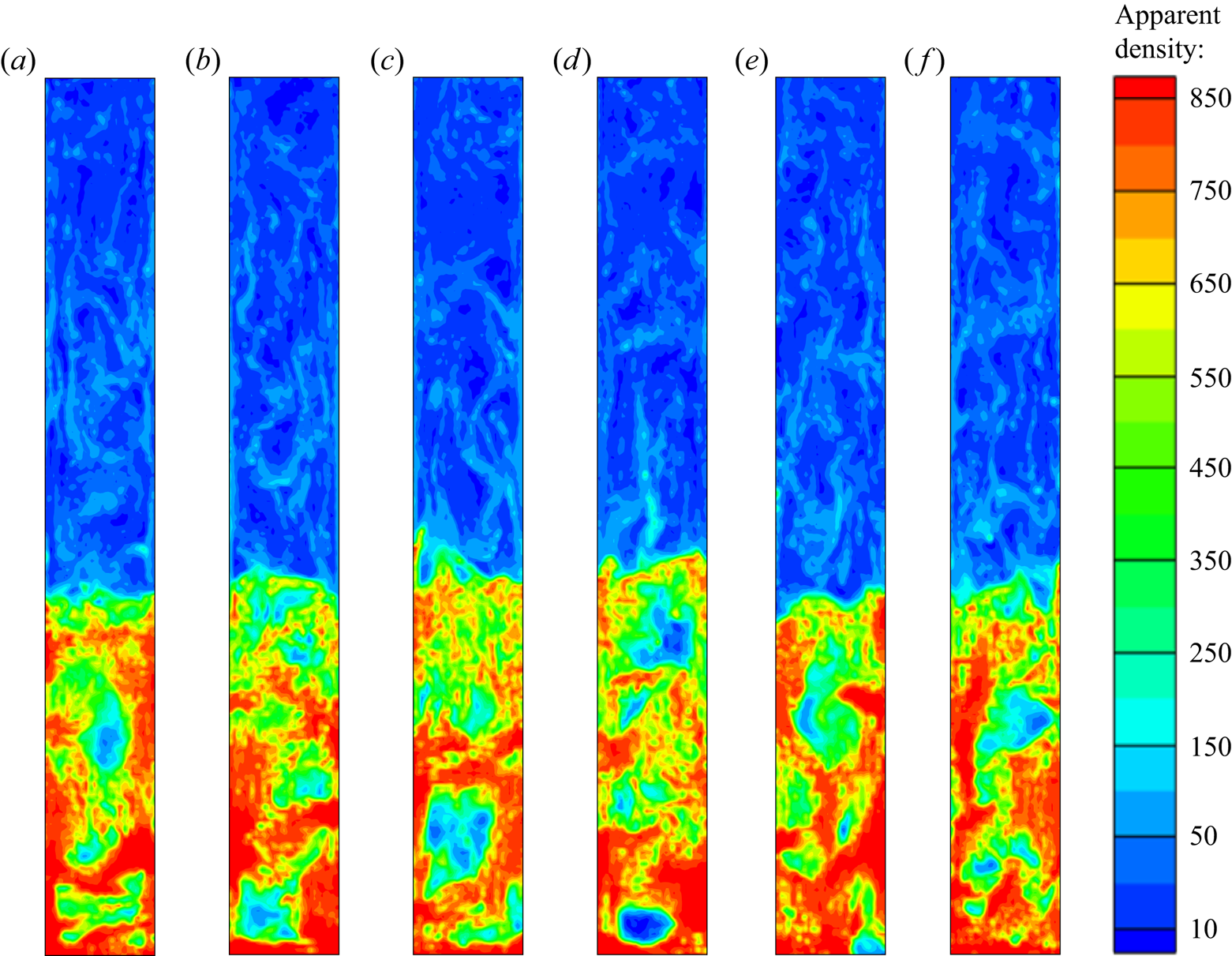

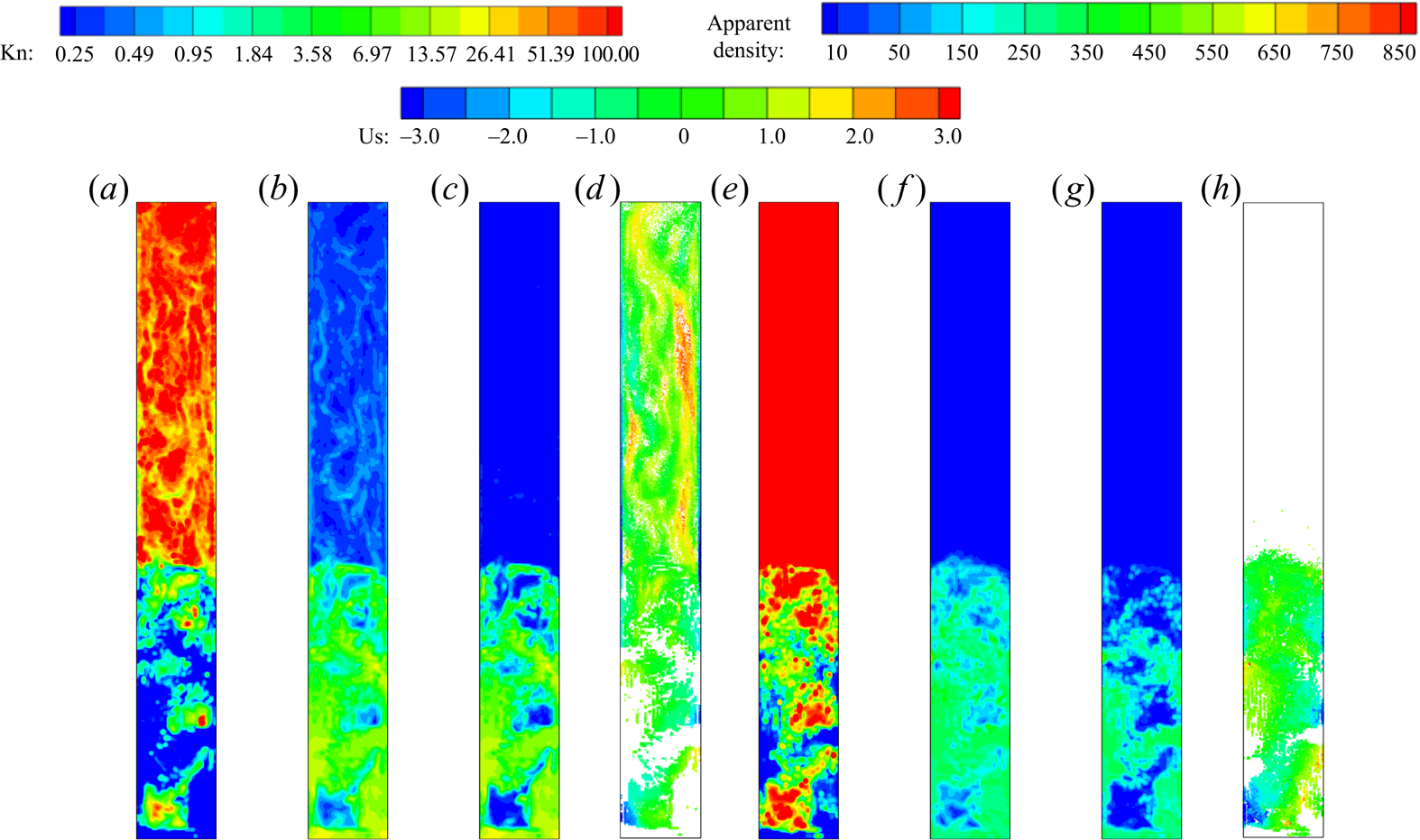

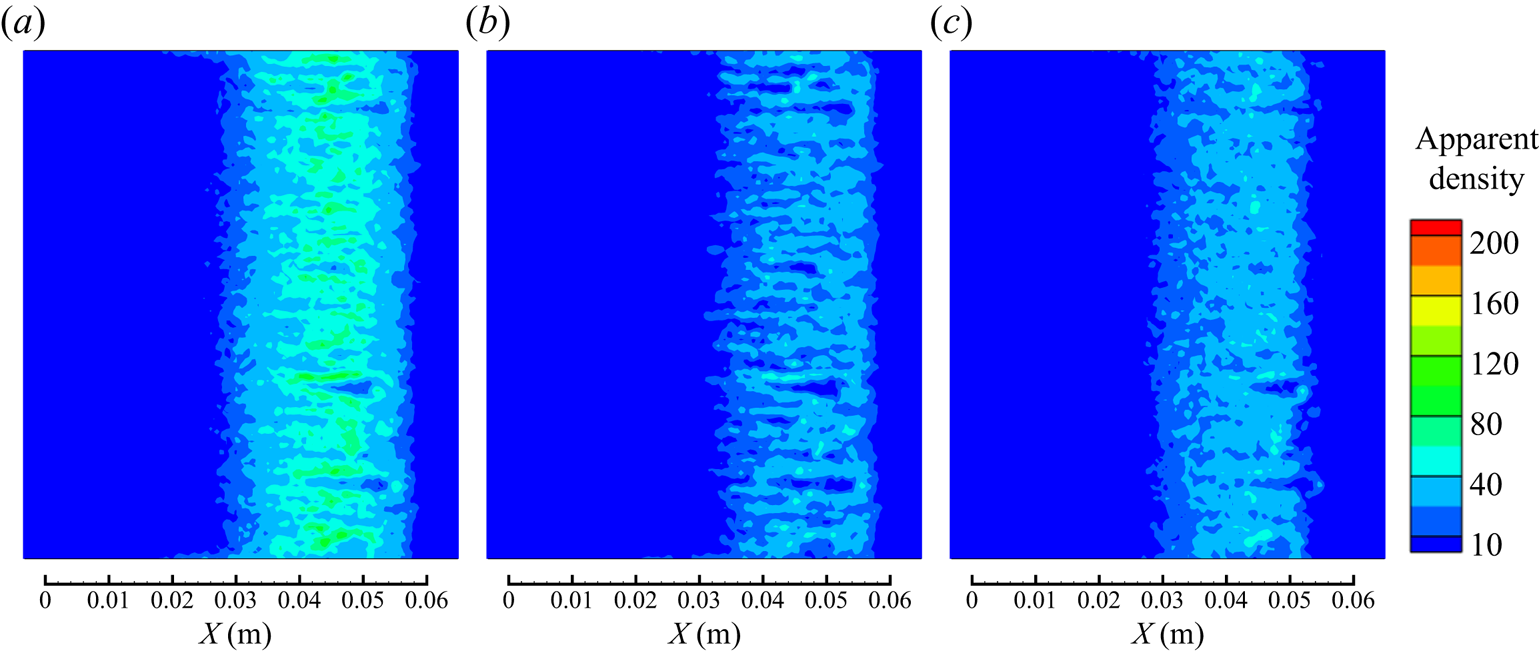

$$\begin{gather} \mathcal{L}_{g1}:\ \left\{\begin{array}{@{}l} \dfrac{\partial (\rho_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\rho_g \boldsymbol{U}_g)= 0, \\ \dfrac{\partial (\rho_g \boldsymbol{U}_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} (\rho_g \boldsymbol{U}_g \boldsymbol{U}_g + p_g\mathbb{I} - \mu_g \boldsymbol{\sigma})= 0,\\ \dfrac{\partial (\rho_g E_g)}{\partial t} + \boldsymbol{\nabla}_x \boldsymbol{\cdot} ((\rho_g E_g + p_g) \boldsymbol{U}_g - \mu_g \boldsymbol{\sigma}\boldsymbol{\cdot}\boldsymbol{U}_g + \kappa \boldsymbol{\nabla}_x T_g ) = 0,\end{array}\right. \end{gather}$$