1. Introduction

Liquid-infused surfaces (LIS) are promising candidates for reducing drag, resisting biofouling and increasing heat transfer in liquid flows (Epstein et al. Reference Epstein, Wong, Belisle, Boggs and Aizenberg2012; Solomon, Khalil & Varanasi Reference Solomon, Khalil and Varanasi2014; Rosenberg et al. Reference Rosenberg, Van Buren, Fu and Smits2016; Sundin et al. Reference Sundin, Ciri, Leonardi, Hultmark and Bagheri2022). These surfaces consist of a solid surface texture with a lubricating liquid that is immiscible with the external fluid. The fluid–fluid interfaces and mobility of the lubricant give rise to a slipping effect of the external flow. LIS can self-repair and are not sensitive to hydrostatic pressure, thereby being more robust than superhydrophobic surfaces (SHS) if designed properly (Wong et al. Reference Wong, Kang, Tang, Smythe, Hatton, Grinthal and Aizenberg2011; Wexler, Jacobi & Stone Reference Wexler, Jacobi and Stone2015; Sundin, Zaleski & Bagheri Reference Sundin, Zaleski and Bagheri2021).

The functionality of LIS has been mostly characterised assuming perfectly clean external liquid flows. However, both in applications and in laboratory set-ups (Jacobi, Wexler & Stone Reference Jacobi, Wexler and Stone2015; Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017), LIS are exposed to trace amounts of surfactants. These are substances that can adsorb onto interfaces and alter the surface (or interfacial) tension. Surfactants influence phenomena such as foaming, wetting, dispersion and emulsification, appearing in a large variety of products, e.g. cleaning agents, paints, cosmetics, pharmaceuticals and motor oils (Rosen & Kunjappu Reference Rosen and Kunjappu2012). It has recently been acknowledged that traces of surfactants may induce Marangoni stresses that counteract the slip of SHS (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017). As we demonstrate in this paper, the presence of surfactants in the system also modifies the slip of LIS. In applications where the mobility of the infusing liquid is crucial, it is necessary to understand the influence of surfactants on the performance, particularly when measured slip lengths deviate significantly from their expected values.

Surfactants adsorbed onto interfaces accumulate at stagnation points when subjected to flow, building up concentration gradients and corresponding Marangoni stresses. The Marangoni stress counteracts the shear stress from the overlying flow, reducing the slip length. Using numerical simulations, a significant slip length reduction of SHS has been observed at bulk concentrations ![]() $c_0 \approx 10^{-3}\,{\rm mol}\,{\rm m}^{-3}$ using properties of the surfactant sodium dodecyl sulphate (SDS) (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017). Most recent experimental studies of SHS, which propose that surfactant gradients lead to slip degradation, have not added surfactants artificially (Kim & Hidrovo Reference Kim and Hidrovo2012; Bolognesi, Cottin-Bizonne & Pirat Reference Bolognesi, Cottin-Bizonne and Pirat2014; Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017; Song et al. Reference Song, Song, Hu, Du, Du, Choi and Rothstein2018; Temprano-Coleto et al. Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021). Instead, the fluid systems have likely been contaminated by the surrounding environment. Indeed, it is generally accepted that surfactants appear as ‘hidden variables’ because their concentrations are unknown (Manikantan & Squires Reference Manikantan and Squires2020). Analytical models that relate the slip length to surfactant concentration are therefore crucial to interpreting experimental measurements.

$c_0 \approx 10^{-3}\,{\rm mol}\,{\rm m}^{-3}$ using properties of the surfactant sodium dodecyl sulphate (SDS) (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017). Most recent experimental studies of SHS, which propose that surfactant gradients lead to slip degradation, have not added surfactants artificially (Kim & Hidrovo Reference Kim and Hidrovo2012; Bolognesi, Cottin-Bizonne & Pirat Reference Bolognesi, Cottin-Bizonne and Pirat2014; Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017; Song et al. Reference Song, Song, Hu, Du, Du, Choi and Rothstein2018; Temprano-Coleto et al. Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021). Instead, the fluid systems have likely been contaminated by the surrounding environment. Indeed, it is generally accepted that surfactants appear as ‘hidden variables’ because their concentrations are unknown (Manikantan & Squires Reference Manikantan and Squires2020). Analytical models that relate the slip length to surfactant concentration are therefore crucial to interpreting experimental measurements.

Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020) developed an analytical theory to predict the effective slip length of SHS from relevant non-dimensional numbers in a two-dimensional channel flow with surfactants. The model assumed low concentrations and uniform interfacial concentration gradients. A high shear rate can result in the upstream part of an interface having almost no surfactant gradients, rendering the model inaccurate. Inspired by the analysis of buoyantly rising bubbles (Palaparthi, Papageorgiou & Maldarelli Reference Palaparthi, Papageorgiou and Maldarelli2006), Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020) found that the surface could enter this regime when interfacial surfactant advection overcomes interfacial diffusion and bulk exchange rates. However, they were unable to find a quantitative condition for the transition. The analytical model compared favourably with numerical simulations for low shear rates, containing four fitted parameters. Baier & Hardt (Reference Baier and Hardt2021) developed an analytical model for slip length degradation by insoluble surfactants. They considered a flow driven by an imposed shear stress and could therefore use the analytical flow solution of Philip (Reference Philip1972a).

The effects of surfactants on LIS have not been investigated thoroughly, although its importance has been acknowledged. Certain interfacial observations of LIS, that cannot be explained fully, have been attributed to the presence of surfactants. One example is the absence of interface deformations in the vicinity of stagnation points (Jacobi et al. Reference Jacobi, Wexler and Stone2015). The influence of surfactants on LIS drag reduction was also highlighted as a future challenge in a recent review (Hardt & McHale Reference Hardt and McHale2022).

There are indications that LIS are more sensitive to surfactants compared with SHS. Dodecane, hexane and other alkanes are promising infusing liquids for drag reduction applications (Van Buren & Smits Reference Van Buren and Smits2017). However, the interfaces of aqueous surfactant solutions and saturated hydrocarbons (e.g. alkanes) generally face a more significant decrease in surface tension than the interfaces of corresponding water–air systems (assuming only minor or no solubility of the surfactant in the hydrocarbon) (Rosen & Kunjappu Reference Rosen and Kunjappu2012). The relatively early publication by Gillap, Weiner & Gibaldi (Reference Gillap, Weiner and Gibaldi1968) reported this effect for sodium decyl sulphate and SDS, and various water–alkane interfaces (e.g. water–hexane with SDS).

Measurements have also shown that the surface tension of water–alkane interfaces can experience an initial decrease of several ![]() ${\rm mN}\,{\rm m}^{-1}$ at minuscule surfactant concentrations. Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019) illustrated this effect for water–hexane interfaces with dodecyl and tridecyl dimethyl phosphine oxide (C

${\rm mN}\,{\rm m}^{-1}$ at minuscule surfactant concentrations. Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019) illustrated this effect for water–hexane interfaces with dodecyl and tridecyl dimethyl phosphine oxide (C![]() $_{12}$DMPO and C

$_{12}$DMPO and C![]() $_{13}$DMPO, lowest concentration

$_{13}$DMPO, lowest concentration ![]() $c_0 = 10^{-6}\,{\rm mol}\,{\rm m}^{-3}$). This effect is also present for several other surfactants such as SDS and trimethyl ammonium bromides (C

$c_0 = 10^{-6}\,{\rm mol}\,{\rm m}^{-3}$). This effect is also present for several other surfactants such as SDS and trimethyl ammonium bromides (C![]() $_{n}$TAB). It is only recently that adsorption models for water–oil interfaces have been developed to account for such phenomena (Fainerman et al. Reference Fainerman2020).

$_{n}$TAB). It is only recently that adsorption models for water–oil interfaces have been developed to account for such phenomena (Fainerman et al. Reference Fainerman2020).

Based on the current knowledge about surfactants at water–oil interfaces, we have investigated the dependency of the slip length of LIS on surfactant concentration. The coupled system of equations for the flow and the surfactants has been solved numerically for transverse grooves in laminar shear flow. In contrast to SHS, it is necessary to resolve the flow both inside and outside the textures of LIS. We also developed an analytical model for the slip length in the presence of surfactants. The model can be used to predict the reduction of slip lengths if the surfactant type and concentration in bulk liquid are known. In settings where surfactants are hidden in the system, the model may be used to estimate the concentration of surfactants given measurements of the slip length.

The flow configuration, governing equations and numerical methods are described in the next section. Section 3 introduces the analytical model for an imposed Marangoni stress. Interfacial surfactant adsorption and desorption of surfactants using regular Frumkin kinetics are described and used for simulations in § 4, followed by the corresponding analytical model (§ 5). A more advanced model giving consistent surface tensions at minuscule concentrations is introduced in § 6. Higher applied shear stresses, resulting in highly skewed interfacial surfactant concentrations (the partial stagnant cap (SC) regime), are treated in § 7. Final remarks and conclusions are presented in §§ 8 and 9, respectively.

2. Configuration, governing equations and numerical method

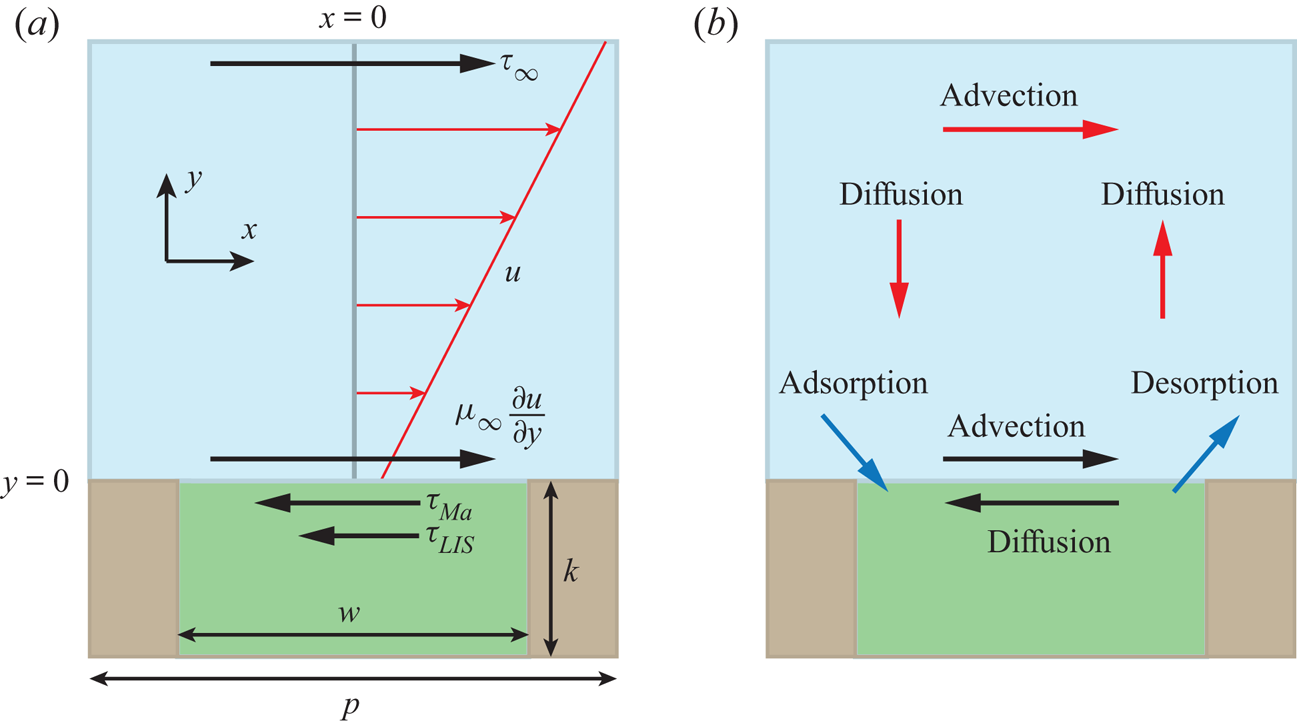

We consider a LIS texture consisting of a periodic array of rectangular transverse grooves subjected to steady laminar flow. Due to the texture periodicity, it is sufficient to consider one interface unit cell with a single groove, sketched in figure 1(a). The groove depth was ![]() $k = 50\,\mathrm {\mu }{\rm m}$, the width

$k = 50\,\mathrm {\mu }{\rm m}$, the width ![]() $w = 2k$, and the pitch

$w = 2k$, and the pitch ![]() $p = 3k$ (groove centre-to-centre distance).

$p = 3k$ (groove centre-to-centre distance).

Figure 1. (a) Interface unit cell, illustrating the balance of stresses at the interface. The velocity profile of the external flow is also shown (red). (b) The physical processes transporting surfactants in the bulk and on the interface and controlling their exchange (red, black and blue arrows, respectively). The external liquid is blue, the infusing liquid green and the solid brown.

The external and infusing fluids have viscosities ![]() $\mu _\infty$ and

$\mu _\infty$ and ![]() $\mu _i$, respectively (

$\mu _i$, respectively (![]() $\mu _\infty = 1.0$ mPa s for water), forming interfaces aligned with the ridges between the grooves. Flat, non-deformable interfaces are assumed in this study so that the sole effect of the surfactants is the Marangoni force. An increased deformation due to a reduction in surface tension is expected to be of secondary importance (Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020).

$\mu _\infty = 1.0$ mPa s for water), forming interfaces aligned with the ridges between the grooves. Flat, non-deformable interfaces are assumed in this study so that the sole effect of the surfactants is the Marangoni force. An increased deformation due to a reduction in surface tension is expected to be of secondary importance (Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020).

The flow velocities and texture dimensions are small. Therefore, we use the Stokes equations for a steady incompressible flow,

where ![]() $P$ is the pressure,

$P$ is the pressure, ![]() $\mu$ is the fluid viscosity and

$\mu$ is the fluid viscosity and ![]() $\boldsymbol {u} = (u,v)$ is the fluid velocity with streamwise and wall-normal components

$\boldsymbol {u} = (u,v)$ is the fluid velocity with streamwise and wall-normal components ![]() $u$ and

$u$ and ![]() $v$, respectively. The streamwise coordinate is

$v$, respectively. The streamwise coordinate is ![]() $x$ with

$x$ with ![]() $x = 0$ in the centre of the considered fluid–fluid interface, and

$x = 0$ in the centre of the considered fluid–fluid interface, and ![]() $y$ is the wall-normal coordinate with

$y$ is the wall-normal coordinate with ![]() $y = 0$ at the interface. Equations (2.1a,b) are valid for both the external and infusing fluids. No-slip and impermeability conditions (

$y = 0$ at the interface. Equations (2.1a,b) are valid for both the external and infusing fluids. No-slip and impermeability conditions (![]() $\boldsymbol {u} = 0$) were used at solid boundaries. At the interface, the wall-normal velocity was

$\boldsymbol {u} = 0$) were used at solid boundaries. At the interface, the wall-normal velocity was ![]() $v = 0$ and the streamwise velocity

$v = 0$ and the streamwise velocity ![]() $u$ was assumed to be continuous. The balance of shear stress on the interface is (Leal Reference Leal2007)

$u$ was assumed to be continuous. The balance of shear stress on the interface is (Leal Reference Leal2007)

where ![]() $\gamma$ is the surface tension. The velocity gradients in (2.2) have been evaluated precisely above and below the interface (

$\gamma$ is the surface tension. The velocity gradients in (2.2) have been evaluated precisely above and below the interface (![]() $y = 0^+$ and

$y = 0^+$ and ![]() $0^-$, respectively). The imposed shear stress that drives the flow is assumed to be

$0^-$, respectively). The imposed shear stress that drives the flow is assumed to be ![]() $\tau _\infty$ at

$\tau _\infty$ at ![]() $y \to \infty$.

$y \to \infty$.

In order to simplify subsequent notation, we introduce

The balance of stresses is shown in figure 1(a). For no surfactants (![]() $\tau _{{ {Ma}}} = 0$), (2.2) relaxes to the classical interface condition, and for

$\tau _{{ {Ma}}} = 0$), (2.2) relaxes to the classical interface condition, and for ![]() $\tau _{LIS} = 0$, ideal (gas infused) SHS are regained.

$\tau _{LIS} = 0$, ideal (gas infused) SHS are regained.

The surfactants are assumed to be soluble in the water phase and can adsorb at the interfaces (see the sketch in figure 2). Surfactant transport mechanisms are illustrated in figure 1(b). An advection–diffusion equation governs the interfacial surfactant concentration ![]() $\varGamma$,

$\varGamma$,

where ![]() $u_s$ is the velocity of the interface plane (

$u_s$ is the velocity of the interface plane (![]() $y = 0$),

$y = 0$), ![]() $D_s$ is the interface diffusivity and

$D_s$ is the interface diffusivity and ![]() $S$ is a source term describing adsorption and desorption. The source term would be zero for insoluble surfactants. No-flux conditions apply at interface edges (

$S$ is a source term describing adsorption and desorption. The source term would be zero for insoluble surfactants. No-flux conditions apply at interface edges (![]() $\mathrm {d} \varGamma /\mathrm {d}\kern 0.06em x = 0$), and (2.4) is valid for

$\mathrm {d} \varGamma /\mathrm {d}\kern 0.06em x = 0$), and (2.4) is valid for ![]() $-w/2 < x < w/2$. The surface coverage of the interfacial surfactants is

$-w/2 < x < w/2$. The surface coverage of the interfacial surfactants is ![]() $\theta = \varGamma /\varGamma _m = \omega \varGamma$, where

$\theta = \varGamma /\varGamma _m = \omega \varGamma$, where ![]() $\varGamma _m$ is the maximum possible interface concentration and

$\varGamma _m$ is the maximum possible interface concentration and ![]() $\omega$ is the molar area. To increase brevity of the expressions throughout the paper, we use the non-dimensional surfactant concentration,

$\omega$ is the molar area. To increase brevity of the expressions throughout the paper, we use the non-dimensional surfactant concentration, ![]() $\theta$, but the theory is otherwise presented using dimensional quantities.

$\theta$, but the theory is otherwise presented using dimensional quantities.

Figure 2. Schematic illustration of surfactants dissolved in water and adsorbed at a water–alkane interface. The interface is shown pinned to a corner of the solid texture. SDS and C![]() $_{12}$TAB molecules consist of hydrocarbon tails with 12 carbon atoms and hydrophilic head groups (red). Alkane molecules are also hydrocarbon chains. Dodecane and hexane molecules have

$_{12}$TAB molecules consist of hydrocarbon tails with 12 carbon atoms and hydrophilic head groups (red). Alkane molecules are also hydrocarbon chains. Dodecane and hexane molecules have ![]() $12$ and

$12$ and ![]() $6$ carbon atoms, respectively, here assumed to be arranged in straight chains. The different phases have the same colours as in figure 1.

$6$ carbon atoms, respectively, here assumed to be arranged in straight chains. The different phases have the same colours as in figure 1.

The equation governing bulk surfactant concentration ![]() $c$ is

$c$ is

where ![]() $D$ is the (bulk) diffusivity. The adsorption and desorption of surfactants at an interface balance the diffusive flux:

$D$ is the (bulk) diffusivity. The adsorption and desorption of surfactants at an interface balance the diffusive flux:

At solid boundaries, ![]() $\partial c/\partial y = 0$. Sufficiently far above the interface, we assume a constant surfactant concentration

$\partial c/\partial y = 0$. Sufficiently far above the interface, we assume a constant surfactant concentration ![]() $c_0$. The diffusivities were set to

$c_0$. The diffusivities were set to ![]() $D = D_s = 7.0 \times 10^{-10}\,{\rm m}^2\,{\rm s}^{-1}$, which also was used by Peaudecerf et al. (Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017).

$D = D_s = 7.0 \times 10^{-10}\,{\rm m}^2\,{\rm s}^{-1}$, which also was used by Peaudecerf et al. (Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017).

The source term and the Marangoni stresses are described in the following sections. We adopt surface tension and adsorption/desorption models for the two extensively studied surfactants SDS and C![]() $_{12}$TAB on water–air (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017) and water–alkane interfaces (Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). SDS can be found in personal care products, and C

$_{12}$TAB on water–air (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017) and water–alkane interfaces (Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). SDS can be found in personal care products, and C![]() $_{12}$TAB can, for example, be used to stabilise foam (Carey & Stubenrauch Reference Carey and Stubenrauch2009; Rosen & Kunjappu Reference Rosen and Kunjappu2012). These surfactants are illustrated schematically in figure 2. They have hydrophobic hydrocarbon tails with 12 carbon atoms but different hydrophilic (head) groups.

$_{12}$TAB can, for example, be used to stabilise foam (Carey & Stubenrauch Reference Carey and Stubenrauch2009; Rosen & Kunjappu Reference Rosen and Kunjappu2012). These surfactants are illustrated schematically in figure 2. They have hydrophobic hydrocarbon tails with 12 carbon atoms but different hydrophilic (head) groups.

2.1. Numerical method

The numerical simulations were performed using the finite-element solver FreeFem++ (Hecht Reference Hecht2012; Lācis et al. Reference Lcis, U., Sudhakar, Pasche and Bagheri2020). Velocities and surfactant concentrations were discretised using quadratic (![]() $P_2$) finite elements while linear (

$P_2$) finite elements while linear (![]() $P_1$) elements were used for the pressure. The system of (2.1a,b), (2.4) and (2.5) was solved iteratively. The domain consisted of one interface unit cell (figure 1). The external flow domain had a height of

$P_1$) elements were used for the pressure. The system of (2.1a,b), (2.4) and (2.5) was solved iteratively. The domain consisted of one interface unit cell (figure 1). The external flow domain had a height of ![]() $3k$. At the upper boundary, we imposed constant shear stress

$3k$. At the upper boundary, we imposed constant shear stress ![]() $\tau _\infty$, zero wall-normal stress and bulk surfactant concentration

$\tau _\infty$, zero wall-normal stress and bulk surfactant concentration ![]() $c_0$. Periodic boundary conditions were applied in the streamwise direction.

$c_0$. Periodic boundary conditions were applied in the streamwise direction.

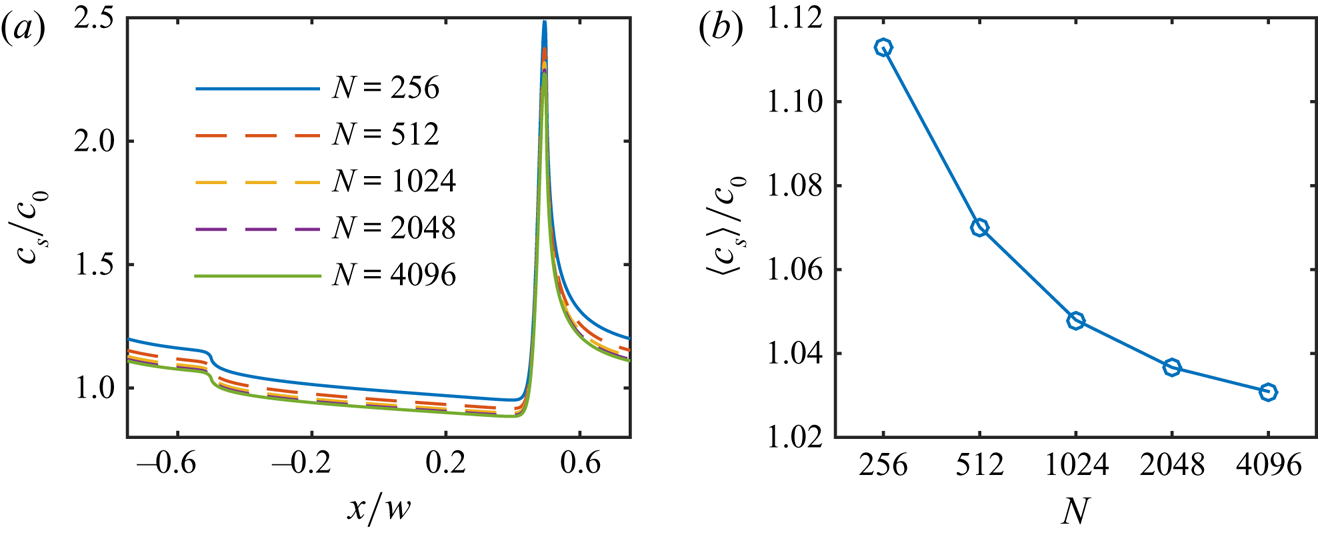

The computational mesh used for the flow (bulk and cavity) and the bulk surfactants (![]() $y \ge 0$) was generated using a built-in tool. The cells were triangular, and the number of cells was prescribed at the different domain boundaries with a spacing of

$y \ge 0$) was generated using a built-in tool. The cells were triangular, and the number of cells was prescribed at the different domain boundaries with a spacing of ![]() $w/N$, where

$w/N$, where ![]() $N = 64$. The grid was refined close to the interface. For the simulations with a low flow speed (§§ 4 and 6), two refinements were made, reducing the sides of the cells by a factor of four in total, i.e.

$N = 64$. The grid was refined close to the interface. For the simulations with a low flow speed (§§ 4 and 6), two refinements were made, reducing the sides of the cells by a factor of four in total, i.e. ![]() $N = 256$. The simulations with artificially applied Marangoni stress (§ 3) also had

$N = 256$. The simulations with artificially applied Marangoni stress (§ 3) also had ![]() $N = 256$ at the interface. For simulations with high flow speed, we used four refinements (

$N = 256$ at the interface. For simulations with high flow speed, we used four refinements (![]() $N = 1024$, § 7). We have also performed grid refinement studies, see Appendix A.

$N = 1024$, § 7). We have also performed grid refinement studies, see Appendix A.

The interfacial surfactant transport equation (2.4) was solved on a one-cell-high mesh with equal cell spacing to the flow and bulk surfactant mesh in the streamwise direction. We imposed periodic boundary conditions in the ![]() $y$-direction. The interface velocity and the bulk surfactant concentration appearing in the source term (

$y$-direction. The interface velocity and the bulk surfactant concentration appearing in the source term (![]() $u_s$ and

$u_s$ and ![]() $c_s$, respectively) were taken at

$c_s$, respectively) were taken at ![]() $y = 0$. There were no variations in the

$y = 0$. There were no variations in the ![]() $y$-direction in the solution of the interfacial surfactant concentration; it exactly corresponds to the one-dimensional solution.

$y$-direction in the solution of the interfacial surfactant concentration; it exactly corresponds to the one-dimensional solution.

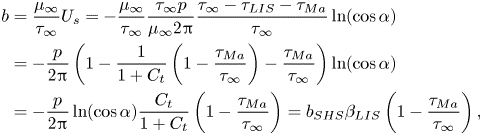

3. Analytical model of a viscous infusing liquid

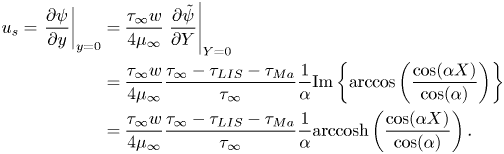

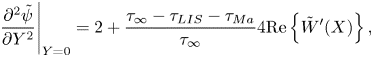

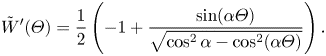

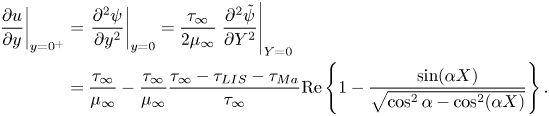

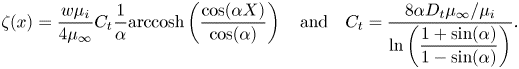

To construct an analytical model of the flow over LIS with surfactants, we assume that the stresses ![]() $\tau _{LIS}$ and

$\tau _{LIS}$ and ![]() $\tau _{{ {Ma}}}$ are constant. Essentially, we combine the models presented by Schönecker, Baier & Hardt (Reference Schönecker, Baier and Hardt2014) and Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). The former considered the flow over LIS without surfactants and assumed

$\tau _{{ {Ma}}}$ are constant. Essentially, we combine the models presented by Schönecker, Baier & Hardt (Reference Schönecker, Baier and Hardt2014) and Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). The former considered the flow over LIS without surfactants and assumed ![]() $\tau _{LIS}$ was constant. The latter work considered flow over SHS and modelled the Marangoni stresses

$\tau _{LIS}$ was constant. The latter work considered flow over SHS and modelled the Marangoni stresses ![]() $\tau _{{ {Ma}}}$ as constant. In this section, we present the analytical model of our system and refer the reader to Appendix B for derivations.

$\tau _{{ {Ma}}}$ as constant. In this section, we present the analytical model of our system and refer the reader to Appendix B for derivations.

The (effective) slip length ![]() $b$ is defined by

$b$ is defined by

where ![]() $\left \langle \right \rangle$ gives the average in the streamwise direction (

$\left \langle \right \rangle$ gives the average in the streamwise direction (![]() $-p/2 < x \le p/2$), and

$-p/2 < x \le p/2$), and ![]() $U_s = \left \langle u \right \rangle$ at

$U_s = \left \langle u \right \rangle$ at ![]() $y = 0$ is the slip velocity. The resulting analytical expression of the effective slip length is (B24)

$y = 0$ is the slip velocity. The resulting analytical expression of the effective slip length is (B24)

where we have introduced the ideal SHS slip length (![]() $\mu _i/\mu _\infty = \tau _{{ {Ma}}}/\tau _\infty = 0$)

$\mu _i/\mu _\infty = \tau _{{ {Ma}}}/\tau _\infty = 0$)

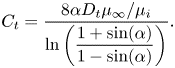

with ![]() $\alpha = ({\rm \pi} /2)(w/p)$. The factor

$\alpha = ({\rm \pi} /2)(w/p)$. The factor ![]() $\beta _{LIS} = C_t/(1 + C_t)$ describes the effects due to the viscous infusing liquid, where

$\beta _{LIS} = C_t/(1 + C_t)$ describes the effects due to the viscous infusing liquid, where ![]() $C_t$ depends on the groove geometry and the viscosity ratio,

$C_t$ depends on the groove geometry and the viscosity ratio,

\begin{equation} C_t = \frac{8\alpha D_t\mu_\infty/\mu_i}{\ln\left(\dfrac{1 + \sin(\alpha)}{1 - \sin(\alpha)}\right)}. \end{equation}

\begin{equation} C_t = \frac{8\alpha D_t\mu_\infty/\mu_i}{\ln\left(\dfrac{1 + \sin(\alpha)}{1 - \sin(\alpha)}\right)}. \end{equation}

The parameter ![]() $D_t$ is a normalised maximum local slip length (B22). Equation (3.2) describes the slip length as a linear function of the Marangoni stress. Similarly, the velocity at the centre of the interface is (B25)

$D_t$ is a normalised maximum local slip length (B22). Equation (3.2) describes the slip length as a linear function of the Marangoni stress. Similarly, the velocity at the centre of the interface is (B25)

where

What remains is to find an explicit expression for ![]() $\tau _{{ {Ma}}}$. However, we can compare the expression for

$\tau _{{ {Ma}}}$. However, we can compare the expression for ![]() $b$ in (3.2) to simulations of (2.1a,b) and (2.2) with an artificially applied

$b$ in (3.2) to simulations of (2.1a,b) and (2.2) with an artificially applied ![]() $\tau _{{ {Ma}}}$. A comparison is shown in figure 3, with a convincing agreement. The two examined viscosity ratios were

$\tau _{{ {Ma}}}$. A comparison is shown in figure 3, with a convincing agreement. The two examined viscosity ratios were ![]() $\mu _i/\mu _\infty = 1.4$ and

$\mu _i/\mu _\infty = 1.4$ and ![]() $0.33$, corresponding to water–dodecane and water–hexane interfaces, respectively (table 1). For both viscosity ratios,

$0.33$, corresponding to water–dodecane and water–hexane interfaces, respectively (table 1). For both viscosity ratios, ![]() $b$ decreases from

$b$ decreases from ![]() $b_{SHS}\beta _{LIS}$ to

$b_{SHS}\beta _{LIS}$ to ![]() $0$ when

$0$ when ![]() $\tau _{{ {Ma}}}/\tau _\infty$ increases from

$\tau _{{ {Ma}}}/\tau _\infty$ increases from ![]() $0$ to

$0$ to ![]() $1$, as predicted by (3.2). The resulting slip length is higher for water–hexane interfaces (for the same

$1$, as predicted by (3.2). The resulting slip length is higher for water–hexane interfaces (for the same ![]() $\tau _{{ {Ma}}}/\tau _\infty$) because of the lower viscosity ratio.

$\tau _{{ {Ma}}}/\tau _\infty$) because of the lower viscosity ratio.

Figure 3. Comparison of (3.2) to simulation results where ![]() $\tau _{{ {Ma}}}$ was applied artificially. The viscosity ratio was set to

$\tau _{{ {Ma}}}$ was applied artificially. The viscosity ratio was set to ![]() $\mu _i/\mu _\infty = 1.4$ or

$\mu _i/\mu _\infty = 1.4$ or ![]() $0.33$ (corresponding to water–dodecane or water–hexane, respectively).

$0.33$ (corresponding to water–dodecane or water–hexane, respectively).

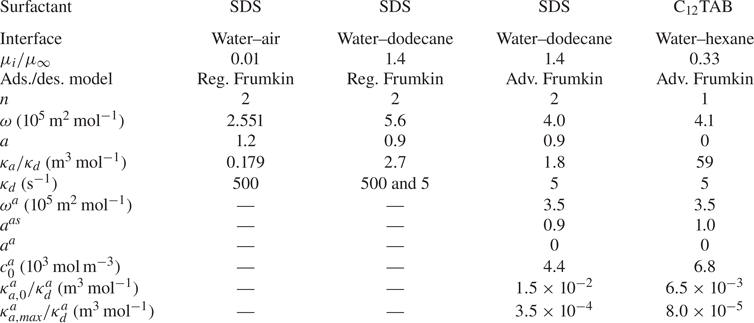

Table 1. Parameters used for SDS at water–air and water–dodecane interfaces and C![]() $_{12}$TAB at water–hexane interfaces. Reg. Frumkin refers to the model expressed by (4.1) and (4.2) and Adv. Frumkin to (6.1), (6.2) and (6.4). For all set-ups, we assume

$_{12}$TAB at water–hexane interfaces. Reg. Frumkin refers to the model expressed by (4.1) and (4.2) and Adv. Frumkin to (6.1), (6.2) and (6.4). For all set-ups, we assume ![]() $D = D_s = 7.0 \times 10^{-10}\,{\rm m}^2\,{\rm s}^{-1}$.

$D = D_s = 7.0 \times 10^{-10}\,{\rm m}^2\,{\rm s}^{-1}$.

4. Adsorption and desorption with regular Frumkin kinetics

The interfacial adsorption and desorption rates determine the source term ![]() $S$. These rates have in recent studies of SHS been modelled by Frumkin kinetics (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017; Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020), which are consistent with the Frumkin isotherm (Chang & Franses Reference Chang and Franses1995). Therefore, we also adopt Frumkin kinetics for this investigation. The source term becomes

$S$. These rates have in recent studies of SHS been modelled by Frumkin kinetics (Peaudecerf et al. Reference Peaudecerf, Landel, Goldstein and Luzzatto-Fegiz2017; Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020), which are consistent with the Frumkin isotherm (Chang & Franses Reference Chang and Franses1995). Therefore, we also adopt Frumkin kinetics for this investigation. The source term becomes

where ![]() $c_s$ is the value of

$c_s$ is the value of ![]() $c$ at the interfaces (dependent on

$c$ at the interfaces (dependent on ![]() $x$),

$x$), ![]() $a$ is a constant,

$a$ is a constant, ![]() $\kappa _{a}$ is the adsorption coefficient and

$\kappa _{a}$ is the adsorption coefficient and ![]() $\kappa _{d}$ is the desorption coefficient. If the surfactant molecules are mutually attractive,

$\kappa _{d}$ is the desorption coefficient. If the surfactant molecules are mutually attractive, ![]() $a$ is positive, and if they are repulsive,

$a$ is positive, and if they are repulsive, ![]() $a$ is negative (Manikantan & Squires Reference Manikantan and Squires2020). In equilibrium, adsorption and desorption fluxes balance (i.e.

$a$ is negative (Manikantan & Squires Reference Manikantan and Squires2020). In equilibrium, adsorption and desorption fluxes balance (i.e. ![]() $S = 0$), and it is sufficient to state

$S = 0$), and it is sufficient to state ![]() $\kappa _{a}/\kappa _{d}$ instead of the individual values of

$\kappa _{a}/\kappa _{d}$ instead of the individual values of ![]() $\kappa _{a}$ and

$\kappa _{a}$ and ![]() $\kappa _{d}$.

$\kappa _{d}$.

The expression for the surface tension (equation of state) corresponding to the Frumkin isotherm is

where ![]() $\gamma _c$ is the surface tension for

$\gamma _c$ is the surface tension for ![]() $\theta = 0$,

$\theta = 0$, ![]() $R = 8.314\,\mathrm {J}\,(\mathrm {K}\,\mathrm {mol})^{-1}$ is the universal gas constant,

$R = 8.314\,\mathrm {J}\,(\mathrm {K}\,\mathrm {mol})^{-1}$ is the universal gas constant, ![]() $T = 293\,\mathrm {K}$ (at

$T = 293\,\mathrm {K}$ (at ![]() $20\,^{\circ }{\rm C}$) is the absolute temperature and

$20\,^{\circ }{\rm C}$) is the absolute temperature and ![]() $n$ is a constant. The factor

$n$ is a constant. The factor ![]() $n$ can account for the adsorption of counter-ions (Chang & Franses Reference Chang and Franses1995; Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). Without a supporting electrolyte, SDS has

$n$ can account for the adsorption of counter-ions (Chang & Franses Reference Chang and Franses1995; Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). Without a supporting electrolyte, SDS has ![]() $n = 2$, which is the value used here. We assume that the data used for C

$n = 2$, which is the value used here. We assume that the data used for C![]() $_{12}$TAB were obtained using a solution with a sufficiently high concentration of supporting electrolyte so that

$_{12}$TAB were obtained using a solution with a sufficiently high concentration of supporting electrolyte so that ![]() $n = 1$. It is generally accepted that the equilibrium model (4.2) can be used in non-equilibrium conditions (Chang & Franses Reference Chang and Franses1995).

$n = 1$. It is generally accepted that the equilibrium model (4.2) can be used in non-equilibrium conditions (Chang & Franses Reference Chang and Franses1995).

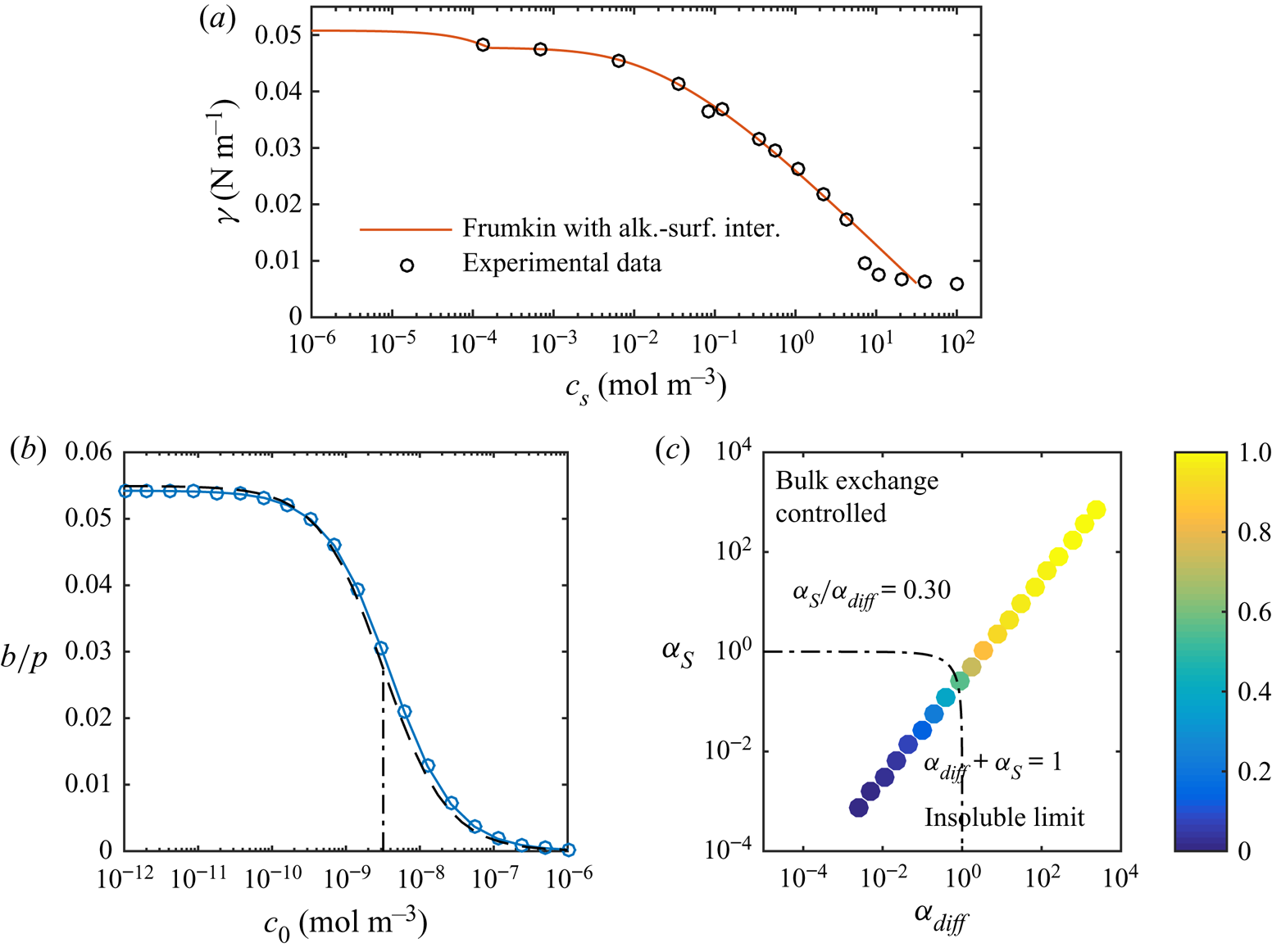

We performed simulations of SDS on water–dodecane interfaces with regular Frumkin kinetics ((4.1) and (4.2)). We increased the concentration ![]() $c_0$ in steps starting from

$c_0$ in steps starting from ![]() $10^{-8}\,{\rm mol}\,{\rm m}^{-3}$. Equilibrium parameters were adapted from Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019), compensated for not explicitly considering interactions of surfactant–alkane molecules (§ 6). These parameters are summarised in table 1 and result in an equilibrium-state surface tension shown in figure 4. The figure also contains experimental data from Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). Regular Frumkin kinetics can describe the measurements but not the correct asymptotic behaviour at minuscule concentrations.

$10^{-8}\,{\rm mol}\,{\rm m}^{-3}$. Equilibrium parameters were adapted from Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019), compensated for not explicitly considering interactions of surfactant–alkane molecules (§ 6). These parameters are summarised in table 1 and result in an equilibrium-state surface tension shown in figure 4. The figure also contains experimental data from Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). Regular Frumkin kinetics can describe the measurements but not the correct asymptotic behaviour at minuscule concentrations.

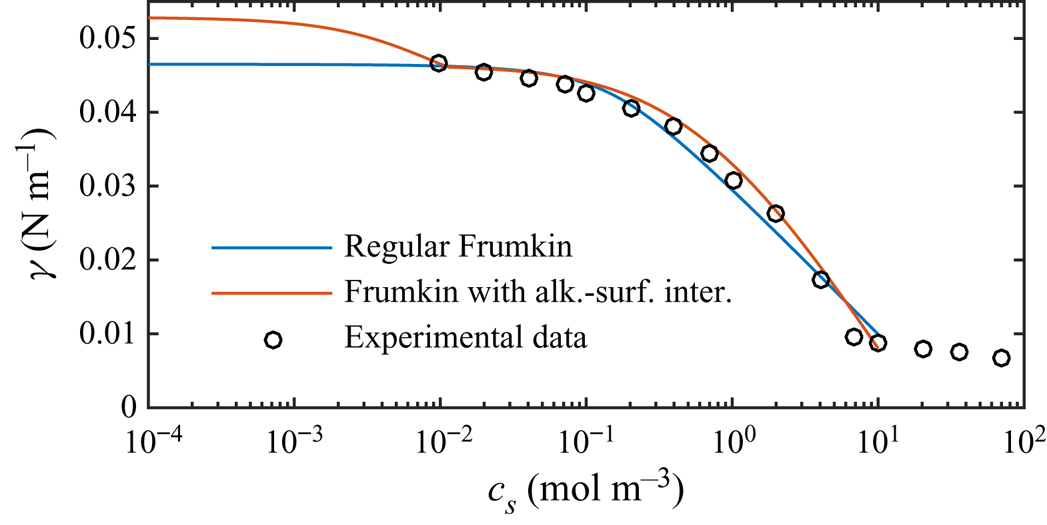

Figure 4. Equilibrium surface tension (![]() $S = 0$) of SDS on a water–dodecane interface, comparing experimental data of Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019) with the regular Frumkin model and a Frumkin model taking into account alkane–surfactant interaction. The surface tension is

$S = 0$) of SDS on a water–dodecane interface, comparing experimental data of Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019) with the regular Frumkin model and a Frumkin model taking into account alkane–surfactant interaction. The surface tension is ![]() $\gamma _c = 52.87\,{\rm mN}\,{\rm m}^{-1}$ for water–dodecane without surfactants at

$\gamma _c = 52.87\,{\rm mN}\,{\rm m}^{-1}$ for water–dodecane without surfactants at ![]() $20\,^{\circ }{\rm C}$ (Zeppieri, Rodríguez & López de Ramos Reference Zeppieri, Rodríguez and López de Ramos2001). In contrast to water–air interfaces, the regular Frumkin model does not exhibit the correct asymptotic behaviour when

$20\,^{\circ }{\rm C}$ (Zeppieri, Rodríguez & López de Ramos Reference Zeppieri, Rodríguez and López de Ramos2001). In contrast to water–air interfaces, the regular Frumkin model does not exhibit the correct asymptotic behaviour when ![]() $c_s \to 0$ at the water–oil interfaces.

$c_s \to 0$ at the water–oil interfaces.

Next, we consider the non-equilibrium system by imposing an external shear stress. As a reference to SDS on water–dodecane interfaces, we also simulated SDS on water–air interfaces, starting at ![]() $c_0 = 10^{-7}\,{\rm mol}\,{\rm m}^{-3}$. Air–water parameters for equilibrium were taken from Prosser & Franses (Reference Prosser and Franses2001). The relatively low imposed shear stress was

$c_0 = 10^{-7}\,{\rm mol}\,{\rm m}^{-3}$. Air–water parameters for equilibrium were taken from Prosser & Franses (Reference Prosser and Franses2001). The relatively low imposed shear stress was ![]() ${\tau _\infty = 0.33}$ mPa; the effects of increased shear stress are described in § 7. The non-equilibrium parameter

${\tau _\infty = 0.33}$ mPa; the effects of increased shear stress are described in § 7. The non-equilibrium parameter ![]() $\kappa _d = 500\,{\rm s}^{-1}$ of the air–water interfaces corresponds to the value reported by Chang & Franses (Reference Chang and Franses1995). This value was determined using empirically modified Langmuir–Hinshelwood kinetics. This model allows

$\kappa _d = 500\,{\rm s}^{-1}$ of the air–water interfaces corresponds to the value reported by Chang & Franses (Reference Chang and Franses1995). This value was determined using empirically modified Langmuir–Hinshelwood kinetics. This model allows ![]() $\kappa _d$ to vary with concentration and includes an exponential factor in the adsorption flux similar to the desorption flux (cf. (4.1)). The value used here corresponds to the lowest bulk concentration (

$\kappa _d$ to vary with concentration and includes an exponential factor in the adsorption flux similar to the desorption flux (cf. (4.1)). The value used here corresponds to the lowest bulk concentration (![]() $1.7\,{\rm mol}\,{\rm m}^{-3}$). For the water–dodecane system, we used both

$1.7\,{\rm mol}\,{\rm m}^{-3}$). For the water–dodecane system, we used both ![]() $\kappa _d = 500$ and

$\kappa _d = 500$ and ![]() $5\,{\rm s}^{-1}$, with minor differences. The latter implies a lower desorption rate. For all other simulations, we used

$5\,{\rm s}^{-1}$, with minor differences. The latter implies a lower desorption rate. For all other simulations, we used ![]() $\kappa _d = 5\,{\rm s}^{-1}$.

$\kappa _d = 5\,{\rm s}^{-1}$.

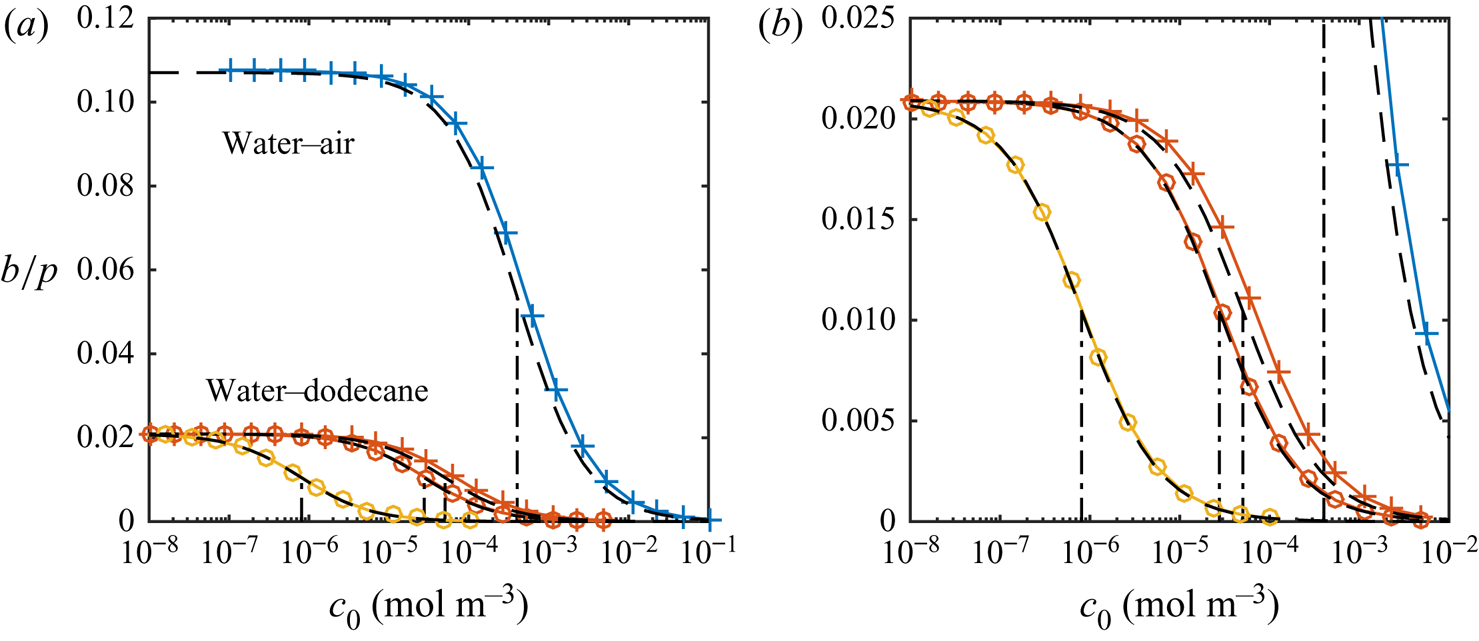

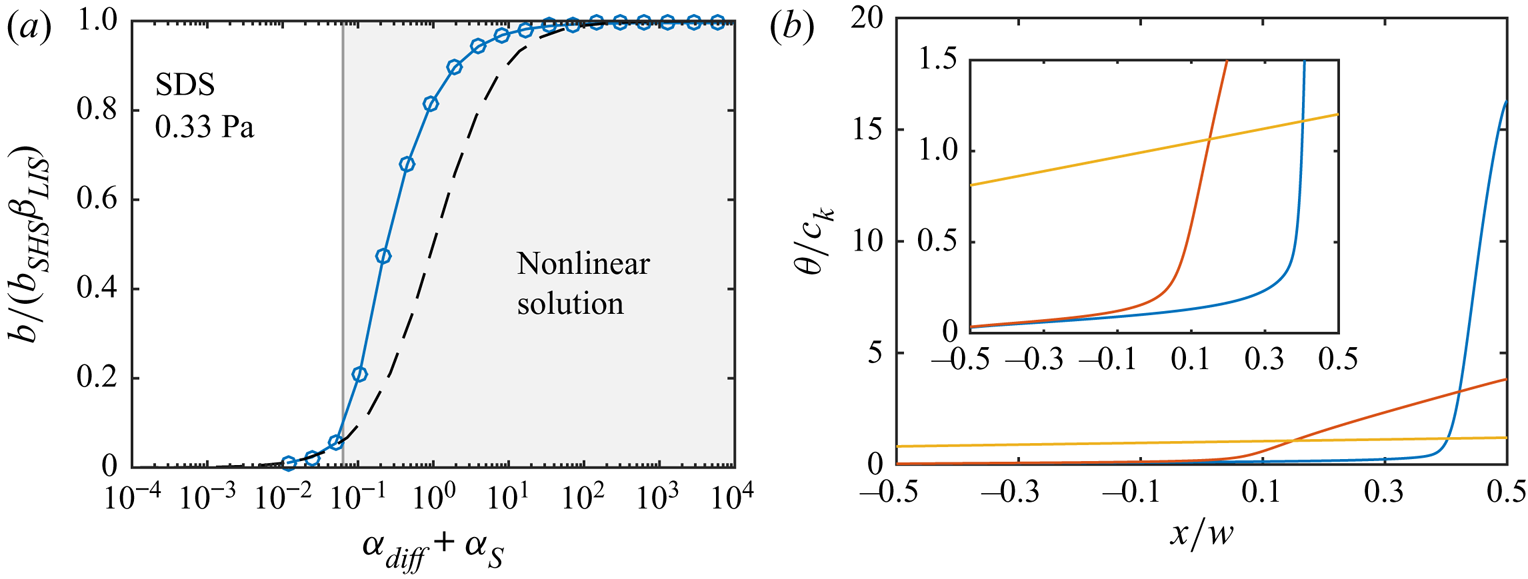

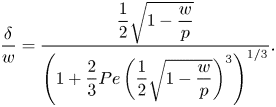

Figure 5(a) shows the resulting slip lengths as a function of ![]() $c_0$, and figure 5(b) provides an enlarged view. The water–air and water–dodecane results are shown in blue and red, respectively. Results for the advanced adsorption model are also included in the figure (yellow markers, see § 6). The slip length is approximately five times higher for the SHS without surfactants (

$c_0$, and figure 5(b) provides an enlarged view. The water–air and water–dodecane results are shown in blue and red, respectively. Results for the advanced adsorption model are also included in the figure (yellow markers, see § 6). The slip length is approximately five times higher for the SHS without surfactants (![]() $c_0 = 0\,{\rm mol}\,{\rm m}^{-3}$). As

$c_0 = 0\,{\rm mol}\,{\rm m}^{-3}$). As ![]() $c_0$ increases, the slip length of both systems decreases. The bulk concentration giving a significantly decreased slip length (

$c_0$ increases, the slip length of both systems decreases. The bulk concentration giving a significantly decreased slip length (![]() $b/(b_{SHS}\beta _{LIS}) \approx 0.5$) is around one order of magnitude smaller for the water–dodecane than the water–air system, marked by vertical dash-dotted lines in figure 5. For the water–air system and the water–dodecane systems (

$b/(b_{SHS}\beta _{LIS}) \approx 0.5$) is around one order of magnitude smaller for the water–dodecane than the water–air system, marked by vertical dash-dotted lines in figure 5. For the water–air system and the water–dodecane systems (![]() $\kappa _d = 500\,{\rm s}^{-1}$), these concentrations are

$\kappa _d = 500\,{\rm s}^{-1}$), these concentrations are ![]() $c_0 = 4\times 10^{-4}$ and

$c_0 = 4\times 10^{-4}$ and ![]() $5\times 10^{-5}\,{\rm mol}\,{\rm m}^{-3}$, respectively. This difference reflects the equilibrium surface tension behaviour. In order to explain the results in more detail, we continue to develop the analytical model of § 3 in § 5. This analytical model is also included in figure 5 (dashed lines).

$5\times 10^{-5}\,{\rm mol}\,{\rm m}^{-3}$, respectively. This difference reflects the equilibrium surface tension behaviour. In order to explain the results in more detail, we continue to develop the analytical model of § 3 in § 5. This analytical model is also included in figure 5 (dashed lines).

Figure 5. Parametric study of slip length at ![]() $\tau _\infty = 0.33$ mPa for different bulk concentrations of SDS with a water–air (blue) and a water–dodecane interface (red regular model, yellow advanced model), together with the analytical model (dashed lines). SHS and LIS results are shown in (a), and an enlarged view of the LIS results is shown in (b). Symbols refer to

$\tau _\infty = 0.33$ mPa for different bulk concentrations of SDS with a water–air (blue) and a water–dodecane interface (red regular model, yellow advanced model), together with the analytical model (dashed lines). SHS and LIS results are shown in (a), and an enlarged view of the LIS results is shown in (b). Symbols refer to ![]() $\kappa _d = 5$ (

$\kappa _d = 5$ (![]() $\circ$) and

$\circ$) and ![]() $500$ (

$500$ (![]() $+$) s

$+$) s![]() $^{-1}$. The vertical dash-dotted lines mark

$^{-1}$. The vertical dash-dotted lines mark ![]() $\alpha _{diff} + \alpha _S = 1$, corresponding to

$\alpha _{diff} + \alpha _S = 1$, corresponding to ![]() $b/(b_{SHS}\beta _{LIS}) \approx 1/2$ (5.16).

$b/(b_{SHS}\beta _{LIS}) \approx 1/2$ (5.16).

The analytical model predicts that the slip length becomes independent of ![]() $\kappa _d$ when this parameter is sufficiently large. At these desorption rates, diffusion of bulk surfactants becomes the limiting process (Damköhler number

$\kappa _d$ when this parameter is sufficiently large. At these desorption rates, diffusion of bulk surfactants becomes the limiting process (Damköhler number ![]() ${ {Da}}_\delta \gg 1$). Temprano-Coleto et al. (Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021) recently discussed this independence, using

${ {Da}}_\delta \gg 1$). Temprano-Coleto et al. (Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021) recently discussed this independence, using ![]() $\kappa _d = 0.75\,{\rm s}^{-1}$ with good agreement with the experimental results of SHS with surfactants naturally occurring in their experimental setting.

$\kappa _d = 0.75\,{\rm s}^{-1}$ with good agreement with the experimental results of SHS with surfactants naturally occurring in their experimental setting.

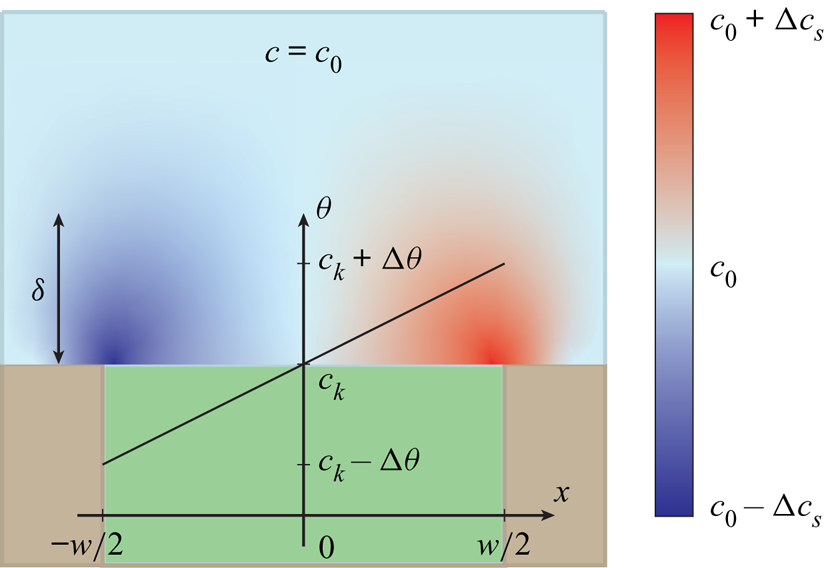

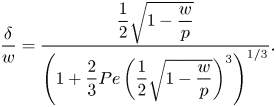

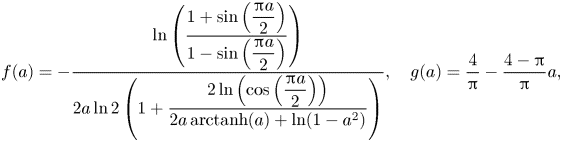

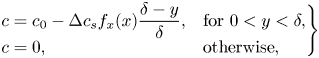

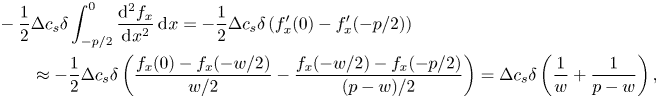

5. Analytical model of surfactant transport

The analytical model of surfactant transport discussed here uses similar core assumptions to previous works (Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). It is assumed that interfacial concentrations are low (![]() $\theta \ll 1$) so that the governing equations (4.1) and (4.2) can be linearised. A second assumption is that bulk and interfacial surfactant concentrations vary linearly over the interfaces (figure 6). Such distributions imply approximately constant surface tension gradients, i.e. the uniformly retarded regime.

$\theta \ll 1$) so that the governing equations (4.1) and (4.2) can be linearised. A second assumption is that bulk and interfacial surfactant concentrations vary linearly over the interfaces (figure 6). Such distributions imply approximately constant surface tension gradients, i.e. the uniformly retarded regime.

Figure 6. Illustration of the distributions of bulk and interfacial surfactant concentrations (![]() $c$ and

$c$ and ![]() $\theta$, respectively) of the analytical model. It is assumed that

$\theta$, respectively) of the analytical model. It is assumed that ![]() $c$ and

$c$ and ![]() $\theta$ vary linearly over the interfaces. The infusing liquid and the solid colours are the same as in figure 1.

$\theta$ vary linearly over the interfaces. The infusing liquid and the solid colours are the same as in figure 1.

5.1. Modelling bulk exchange

For a steady flow, there is a balance between adsorption and desorption processes. The integral of (2.6) over the interfaces must then be zero,

\begin{equation} D\int_{{-}w/2}^{w/2}\left.\frac{\partial c}{\partial y}\right|_{y = 0}\, \mathrm{d}\kern0.06em x = \int_{{-}w/2}^{w/2}S \,\mathrm{d}\kern0.06em x = 0. \end{equation}

\begin{equation} D\int_{{-}w/2}^{w/2}\left.\frac{\partial c}{\partial y}\right|_{y = 0}\, \mathrm{d}\kern0.06em x = \int_{{-}w/2}^{w/2}S \,\mathrm{d}\kern0.06em x = 0. \end{equation}

This condition implies the existence of a point ![]() $x_0$ on an interface where

$x_0$ on an interface where ![]() $D\partial c/\partial y |_{y = 0} = S = 0$. As the wall-normal derivative of

$D\partial c/\partial y |_{y = 0} = S = 0$. As the wall-normal derivative of ![]() $c$ is zero at this location, we have

$c$ is zero at this location, we have ![]() $c_s \approx c_0$. The linearised source term (4.1) is

$c_s \approx c_0$. The linearised source term (4.1) is

where we have introduced the non-dimensional bulk surfactant concentration ![]() ${c_k = \kappa _ac_0/\kappa _d}$. From the linearised source term,

${c_k = \kappa _ac_0/\kappa _d}$. From the linearised source term,

Due to advection, ![]() $\theta$ decreases upstream and increases downstream of

$\theta$ decreases upstream and increases downstream of ![]() $x_0$. It is assumed that

$x_0$. It is assumed that ![]() $x_0 \approx 0$, that

$x_0 \approx 0$, that ![]() $\theta$ varies around

$\theta$ varies around ![]() $c_{k}$ by

$c_{k}$ by ![]() $\pm \Delta \theta$, and in the same way

$\pm \Delta \theta$, and in the same way ![]() $c_s$ around

$c_s$ around ![]() $c_0$ by

$c_0$ by ![]() $\pm \Delta c_s$. These assumed concentration distributions imply (using (2.6) and (5.2)),

$\pm \Delta c_s$. These assumed concentration distributions imply (using (2.6) and (5.2)),

where ![]() ${ {Da}} = \kappa _a w/(\omega D)$ is the Damköhler number (Temprano-Coleto et al. Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021).

${ {Da}} = \kappa _a w/(\omega D)$ is the Damköhler number (Temprano-Coleto et al. Reference Temprano-Coleto, Smith, Peaudecerf, Landel, Gibou and Luzzatto- Fegiz2021).

From (5.2), a characteristic adsorption flux is given by

in ![]() ${\rm mol}\,({\rm s}\,{\rm m}^2)^{-1}$. Equation (5.3) entails that the characteristic desorption flux is the same:

${\rm mol}\,({\rm s}\,{\rm m}^2)^{-1}$. Equation (5.3) entails that the characteristic desorption flux is the same: ![]() $\kappa _d \theta /\omega \sim \kappa _d c_k/\omega = \kappa _a c_0/\omega$. A corresponding scale for the diffusive flux of bulk surfactants is

$\kappa _d \theta /\omega \sim \kappa _d c_k/\omega = \kappa _a c_0/\omega$. A corresponding scale for the diffusive flux of bulk surfactants is ![]() $D c_0/w$ (2.6). Hence,

$D c_0/w$ (2.6). Hence, ![]() ${ {Da}}$ expresses characteristic adsorption/desorption flux to diffusive flux of bulk surfactants. Corresponding rates are found by multiplication by

${ {Da}}$ expresses characteristic adsorption/desorption flux to diffusive flux of bulk surfactants. Corresponding rates are found by multiplication by ![]() $\omega$. The actual values of

$\omega$. The actual values of ![]() $\Delta \theta$ and

$\Delta \theta$ and ![]() $\Delta c_s$ are neglected, but we do include the characteristic sizes of

$\Delta c_s$ are neglected, but we do include the characteristic sizes of ![]() $\theta$ and

$\theta$ and ![]() $c_s$. This interpretation of

$c_s$. This interpretation of ![]() ${ {Da}}$ is also seen in (5.4); large diffusion flux and low adsorption result in smaller wall-normal derivative of

${ {Da}}$ is also seen in (5.4); large diffusion flux and low adsorption result in smaller wall-normal derivative of ![]() $c$.

$c$.

As pointed out by Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020), (5.4) can be used to estimate the boundary layer thickness ![]() $\delta$ of

$\delta$ of ![]() $c$. Approximating

$c$. Approximating ![]() $\delta$ by

$\delta$ by

\begin{equation} \left.\frac{\partial c}{\partial y}\right|_{y = 0, x ={-}w/2} \approx \frac{\Delta c_s}{\delta} \implies \frac{\Delta c_s}{c_0} \approx \frac{\Delta \theta}{c_k}\frac{{{Da}} \dfrac{\delta}{w}}{1 + {{Da}} \dfrac{\delta}{w}}. \end{equation}

\begin{equation} \left.\frac{\partial c}{\partial y}\right|_{y = 0, x ={-}w/2} \approx \frac{\Delta c_s}{\delta} \implies \frac{\Delta c_s}{c_0} \approx \frac{\Delta \theta}{c_k}\frac{{{Da}} \dfrac{\delta}{w}}{1 + {{Da}} \dfrac{\delta}{w}}. \end{equation}

The modified Damköhler number ![]() ${ {Da}}_\delta = { {Da}} \delta /w$ considers the diffusion length scale of bulk surfactants to be

${ {Da}}_\delta = { {Da}} \delta /w$ considers the diffusion length scale of bulk surfactants to be ![]() $\delta$, which is more appropriate than

$\delta$, which is more appropriate than ![]() $w$ (Palaparthi et al. Reference Palaparthi, Papageorgiou and Maldarelli2006). We see that if the adsorption/desorption rate is much larger than the diffusion rate (

$w$ (Palaparthi et al. Reference Palaparthi, Papageorgiou and Maldarelli2006). We see that if the adsorption/desorption rate is much larger than the diffusion rate (![]() ${ {Da}}_\delta \gg 1$),

${ {Da}}_\delta \gg 1$), ![]() $\Delta c_s/c_0 \approx \Delta \theta /c_k$. Otherwise, if

$\Delta c_s/c_0 \approx \Delta \theta /c_k$. Otherwise, if ![]() ${ {Da}}_\delta \ll 1$,

${ {Da}}_\delta \ll 1$, ![]() $\Delta c_s/c_0 \approx { {Da}}_\delta \Delta \theta /c_k$.

$\Delta c_s/c_0 \approx { {Da}}_\delta \Delta \theta /c_k$.

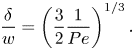

The bulk surfactant transport equation (2.5) implies that ![]() $\delta$ depends on

$\delta$ depends on ![]() $w$ and Péclet number

$w$ and Péclet number ![]() ${ {Pe}} = Uw/D$, where

${ {Pe}} = Uw/D$, where ![]() $U = w\tau _\infty /\mu _\infty$ is the characteristic velocity at

$U = w\tau _\infty /\mu _\infty$ is the characteristic velocity at ![]() $y = w$. Diffusion between boundary layers of adjacent grooves also introduces a dependency on

$y = w$. Diffusion between boundary layers of adjacent grooves also introduces a dependency on ![]() $p$. An analytical estimate (Appendix C) resulted in

$p$. An analytical estimate (Appendix C) resulted in

\begin{equation} \frac{\delta}{w} = \dfrac{\dfrac{1}{2}\sqrt{1 - \dfrac{w}{p}}}{\left(1 + \dfrac{2}{3}{{Pe}}\left(\dfrac{1}{2}\sqrt{1 - \dfrac{w}{p}}\right)^3\right)^{1/3}}. \end{equation}

\begin{equation} \frac{\delta}{w} = \dfrac{\dfrac{1}{2}\sqrt{1 - \dfrac{w}{p}}}{\left(1 + \dfrac{2}{3}{{Pe}}\left(\dfrac{1}{2}\sqrt{1 - \dfrac{w}{p}}\right)^3\right)^{1/3}}. \end{equation}

The left relation of (5.6) was also used to compute ![]() $\delta$ explicitly. It was found that

$\delta$ explicitly. It was found that ![]() $\delta /w = 0.3$ was a relatively good approximation for all tested configurations for the current geometry and

$\delta /w = 0.3$ was a relatively good approximation for all tested configurations for the current geometry and ![]() ${ {Pe}}$ (Appendix C and figure 12a,b), in agreement with (5.7). Deviations were around

${ {Pe}}$ (Appendix C and figure 12a,b), in agreement with (5.7). Deviations were around ![]() ${\pm }0.1$.

${\pm }0.1$.

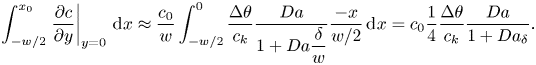

5.2. Interfacial surfactant transport balance

The transport equation for the interfacial surfactant concentration (2.4) expresses a balance between advection, diffusion and adsorption/desorption (compare with figure 1b). We integrate this equation from ![]() $x = -w/2$ to

$x = -w/2$ to ![]() $x = x_0$ and use the boundary condition (2.6),

$x = x_0$ and use the boundary condition (2.6),

Using ![]() $x_0 \approx 0$ and (5.6) with the streamwise dependency (5.4), we have

$x_0 \approx 0$ and (5.6) with the streamwise dependency (5.4), we have

\begin{equation} \int_{{-}w/2}^{x_0} \left.\frac{\partial c}{\partial y}\right|_{y = 0} \,\mathrm{d}\kern0.06em x \approx \frac{c_0}{w}\int_{{-}w/2}^{0} \frac{\Delta \theta}{c_k}\frac{{{Da}}}{1 + {{Da}}\dfrac{\delta}{w}}\frac{-x}{w/2} \,\mathrm{d}\kern0.06em x = c_0\frac{1}{4}\frac{\Delta \theta}{c_k}\frac{{{Da}}}{1 + {{Da}}_\delta}. \end{equation}

\begin{equation} \int_{{-}w/2}^{x_0} \left.\frac{\partial c}{\partial y}\right|_{y = 0} \,\mathrm{d}\kern0.06em x \approx \frac{c_0}{w}\int_{{-}w/2}^{0} \frac{\Delta \theta}{c_k}\frac{{{Da}}}{1 + {{Da}}\dfrac{\delta}{w}}\frac{-x}{w/2} \,\mathrm{d}\kern0.06em x = c_0\frac{1}{4}\frac{\Delta \theta}{c_k}\frac{{{Da}}}{1 + {{Da}}_\delta}. \end{equation}

With (5.3) and ![]() $\mathrm {d} \theta /\mathrm {d}\kern 0.06em x|_{x=x_0} \approx 2\Delta \theta /w$, we obtain an expression for the interface centre velocity,

$\mathrm {d} \theta /\mathrm {d}\kern 0.06em x|_{x=x_0} \approx 2\Delta \theta /w$, we obtain an expression for the interface centre velocity,

with coefficients ![]() $c_1 \approx 2$ and

$c_1 \approx 2$ and ![]() $c_2 \approx 1/4$ resulting from the linear distributions. The interface Péclet number is defined by

$c_2 \approx 1/4$ resulting from the linear distributions. The interface Péclet number is defined by ![]() ${ {Pe}}_s = Uw/D_s$ and the Biot number is defined by

${ {Pe}}_s = Uw/D_s$ and the Biot number is defined by ![]() ${ {Bi}} = c_0D \omega { {Da}} /(U c_k) = \kappa _d w/U$.

${ {Bi}} = c_0D \omega { {Da}} /(U c_k) = \kappa _d w/U$.

The Péclet number ![]() ${ {Pe}}_s$ is a measure of characteristic advection to diffusion rates of the interfacial surfactants, which with (5.3) can be written as

${ {Pe}}_s$ is a measure of characteristic advection to diffusion rates of the interfacial surfactants, which with (5.3) can be written as

respectively. The characteristic adsorption/desorption fluxes (5.5) correspond to a rate ![]() $\kappa _d c_k$. Hence, the Biot number expresses the adsorption/desorption rate to the advection rate of interfacial surfactants.

$\kappa _d c_k$. Hence, the Biot number expresses the adsorption/desorption rate to the advection rate of interfacial surfactants.

For a specific value of ![]() $\Delta \theta /c_k$, (5.10) implies that for

$\Delta \theta /c_k$, (5.10) implies that for ![]() $u_s^0/U$ to be close to zero, the characteristic advection of interfacial surfactants must dominate (i) diffusion of interfacial surfactants (

$u_s^0/U$ to be close to zero, the characteristic advection of interfacial surfactants must dominate (i) diffusion of interfacial surfactants (![]() ${ {Pe}}_s \gg \Delta \theta /c_k$) and (ii) bulk exchange (cf. figure 1b). The bulk exchange may be limited by either adsorption/desorption rate (

${ {Pe}}_s \gg \Delta \theta /c_k$) and (ii) bulk exchange (cf. figure 1b). The bulk exchange may be limited by either adsorption/desorption rate (![]() ${ {Da}}_\delta \ll 1$) or diffusion of bulk surfactants (

${ {Da}}_\delta \ll 1$) or diffusion of bulk surfactants (![]() ${ {Da}}_\delta \gg 1$). If

${ {Da}}_\delta \gg 1$). If ![]() ${ {Da}}_\delta \ll 1$, we must have

${ {Da}}_\delta \ll 1$, we must have ![]() ${ {Bi}} \ll \Delta \theta /c_k$, i.e. advection of interfacial surfactants must dominate over the adsorption/desorption rate. If

${ {Bi}} \ll \Delta \theta /c_k$, i.e. advection of interfacial surfactants must dominate over the adsorption/desorption rate. If ![]() ${ {Da}}_\delta \gg 1$, then we must have

${ {Da}}_\delta \gg 1$, then we must have ![]() ${ {Bi}}/{ {Da}}_\delta \ll \Delta \theta /c_k$: advection of interfacial surfactants must dominate over the diffusion of bulk surfactants.

${ {Bi}}/{ {Da}}_\delta \ll \Delta \theta /c_k$: advection of interfacial surfactants must dominate over the diffusion of bulk surfactants.

The Marangoni stress also dictates the velocity on the interface (3.5). This relationship and (5.10) give a condition for ![]() $\Delta \theta$, derived in the next section.

$\Delta \theta$, derived in the next section.

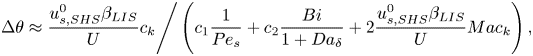

5.3. Corresponding slip length

Linearisation of the Marangoni stresses with surface tension (4.2) implies

where we have introduced the Marangoni number ![]() ${ {Ma}} = nRT/(\omega \mu _\infty U)$. We have chosen to neglect thermal effects (

${ {Ma}} = nRT/(\omega \mu _\infty U)$. We have chosen to neglect thermal effects (![]() $T$ is a constant). The gradient of the surface coverage

$T$ is a constant). The gradient of the surface coverage ![]() $\mathrm {d} \theta /\mathrm {d}\kern 0.06em x$ is generally positive (figure 6), meaning that

$\mathrm {d} \theta /\mathrm {d}\kern 0.06em x$ is generally positive (figure 6), meaning that ![]() $\mathrm {d} \gamma /\mathrm {d}\kern 0.06em x$ is negative, and the Marangoni stresses act in the negative streamwise direction, as shown by figure 1(a). By assuming linear interfacial concentrations,

$\mathrm {d} \gamma /\mathrm {d}\kern 0.06em x$ is negative, and the Marangoni stresses act in the negative streamwise direction, as shown by figure 1(a). By assuming linear interfacial concentrations, ![]() $\mathrm {d} \theta /\mathrm {d}\kern 0.06em x$ can be estimated as

$\mathrm {d} \theta /\mathrm {d}\kern 0.06em x$ can be estimated as ![]() $2\Delta \theta /w$, resulting in

$2\Delta \theta /w$, resulting in

It follows from (3.5) that

Equation (5.13) implies a scaling ![]() $nRT/(\omega w)$ of the Marangoni stress, neglecting

$nRT/(\omega w)$ of the Marangoni stress, neglecting ![]() $\Delta \theta$. As

$\Delta \theta$. As ![]() $\tau _\infty = \mu _\infty U/w$, the Marangoni number expresses the ratio of characteristic Marangoni to imposed shear stresses. If the characteristic size of

$\tau _\infty = \mu _\infty U/w$, the Marangoni number expresses the ratio of characteristic Marangoni to imposed shear stresses. If the characteristic size of ![]() $\theta$ is considered, the Marangoni number transforms to

$\theta$ is considered, the Marangoni number transforms to ![]() ${ {Ma}} c_k$.

${ {Ma}} c_k$.

The velocities expressed by (5.10) and (5.14) must be the same. This equality results in the expression

\begin{equation} \left.\Delta \theta \approx \frac{ u_{s,{SHS}}^0\beta_{LIS}}{U}c_k\right/\left(c_1 \frac{1}{{{Pe}}_s} + c_2\frac{{{Bi}}}{1 + {{Da}}_\delta} + 2\frac{u_{s,{SHS}}^0\beta_{LIS}}{U}{Ma} c_k\right), \end{equation}

\begin{equation} \left.\Delta \theta \approx \frac{ u_{s,{SHS}}^0\beta_{LIS}}{U}c_k\right/\left(c_1 \frac{1}{{{Pe}}_s} + c_2\frac{{{Bi}}}{1 + {{Da}}_\delta} + 2\frac{u_{s,{SHS}}^0\beta_{LIS}}{U}{Ma} c_k\right), \end{equation}

which by (5.13) gives ![]() $\tau _{{ {Ma}}}$. Equation (3.2) then gives the slip length

$\tau _{{ {Ma}}}$. Equation (3.2) then gives the slip length

We have introduced

where ![]() ${ {Pe}}_s' = wu_{s,{SHS}}^0\beta _{LIS}/D_s$ and

${ {Pe}}_s' = wu_{s,{SHS}}^0\beta _{LIS}/D_s$ and ![]() ${ {Bi}}' = \kappa _d w /(u_{s,{SHS}}^0\beta _{LIS}$) are the Péclet and Biot numbers, respectively, with more appropriate velocity scales. The two expressions of (5.17) represent the effects of interfacial surfactant diffusion and bulk exchange on the slip length, respectively. In order to reduce

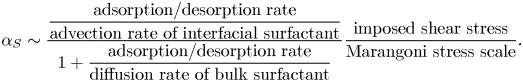

${ {Bi}}' = \kappa _d w /(u_{s,{SHS}}^0\beta _{LIS}$) are the Péclet and Biot numbers, respectively, with more appropriate velocity scales. The two expressions of (5.17) represent the effects of interfacial surfactant diffusion and bulk exchange on the slip length, respectively. In order to reduce ![]() $b$, they must both be small,

$b$, they must both be small, ![]() $\alpha _{diff} \lesssim 1$ and

$\alpha _{diff} \lesssim 1$ and ![]() $\alpha _S \lesssim 1$. Based on the interpretations of the non-dimensional numbers,

$\alpha _S \lesssim 1$. Based on the interpretations of the non-dimensional numbers,

$$\begin{gather}\alpha_{S}

\sim \dfrac{\dfrac{\text{adsorption/desorption

rate}}{\text{advection rate of interfacial surfactant}}}{1

+ \dfrac{\text{adsorption/desorption rate}}{\text{diffusion

rate of bulk surfactant}}}\dfrac{\text{imposed shear

stress}}{\text{Marangoni stress scale}}.

\end{gather}$$

$$\begin{gather}\alpha_{S}

\sim \dfrac{\dfrac{\text{adsorption/desorption

rate}}{\text{advection rate of interfacial surfactant}}}{1

+ \dfrac{\text{adsorption/desorption rate}}{\text{diffusion

rate of bulk surfactant}}}\dfrac{\text{imposed shear

stress}}{\text{Marangoni stress scale}}.

\end{gather}$$Returning to figure 5(a), we can plot the results also from the analytical model, showing a satisfactory agreement with the simulation results. Some central non-dimensional numbers are summarised in table 2.

If ![]() $\alpha _S \gg \alpha _{diff}$, the diffusion of interfacial surfactants is insignificant compared with the bulk exchange. In the opposite situation,

$\alpha _S \gg \alpha _{diff}$, the diffusion of interfacial surfactants is insignificant compared with the bulk exchange. In the opposite situation, ![]() $\alpha _S \ll \alpha _{diff}$, the interfacial diffusion dominates (insoluble limit). For the

$\alpha _S \ll \alpha _{diff}$, the interfacial diffusion dominates (insoluble limit). For the ![]() $\kappa _d = 500\,{\rm s}^{-1}$ water–dodecane and water–air systems, the bulk exchange is much faster than interfacial diffusion (

$\kappa _d = 500\,{\rm s}^{-1}$ water–dodecane and water–air systems, the bulk exchange is much faster than interfacial diffusion (![]() $\alpha _S \gg \alpha _{diff}$). The parameter

$\alpha _S \gg \alpha _{diff}$). The parameter ![]() $\alpha _S$ thereby governs the decrease of slip length for these systems. The values of

$\alpha _S$ thereby governs the decrease of slip length for these systems. The values of ![]() ${ {Da}}_\delta$ are

${ {Da}}_\delta$ are ![]() $97$ and

$97$ and ![]() $14$, respectively. As

$14$, respectively. As ![]() ${ {Da}}_\delta \gg 1$, the bulk exchange rate is limited by the diffusion of bulk surfactants, implying that

${ {Da}}_\delta \gg 1$, the bulk exchange rate is limited by the diffusion of bulk surfactants, implying that ![]() $\alpha _S$ depends on

$\alpha _S$ depends on ![]() $\kappa _d/\kappa _a$ (

$\kappa _d/\kappa _a$ (![]() ${ {Bi}}'/{ {Da}}_\delta$) instead of

${ {Bi}}'/{ {Da}}_\delta$) instead of ![]() $\kappa _d$ (

$\kappa _d$ (![]() ${ {Bi}}'$). For the water–dodecane system,

${ {Bi}}'$). For the water–dodecane system, ![]() $\kappa _d = 5\,{\rm s}^{-1}$ corresponds to

$\kappa _d = 5\,{\rm s}^{-1}$ corresponds to ![]() ${ {Da}}_\delta = 0.97$, below which the condition (5.16) becomes more strict as then

${ {Da}}_\delta = 0.97$, below which the condition (5.16) becomes more strict as then ![]() $\alpha _S$ becomes approximately proportional to

$\alpha _S$ becomes approximately proportional to ![]() $\kappa _d$.

$\kappa _d$.

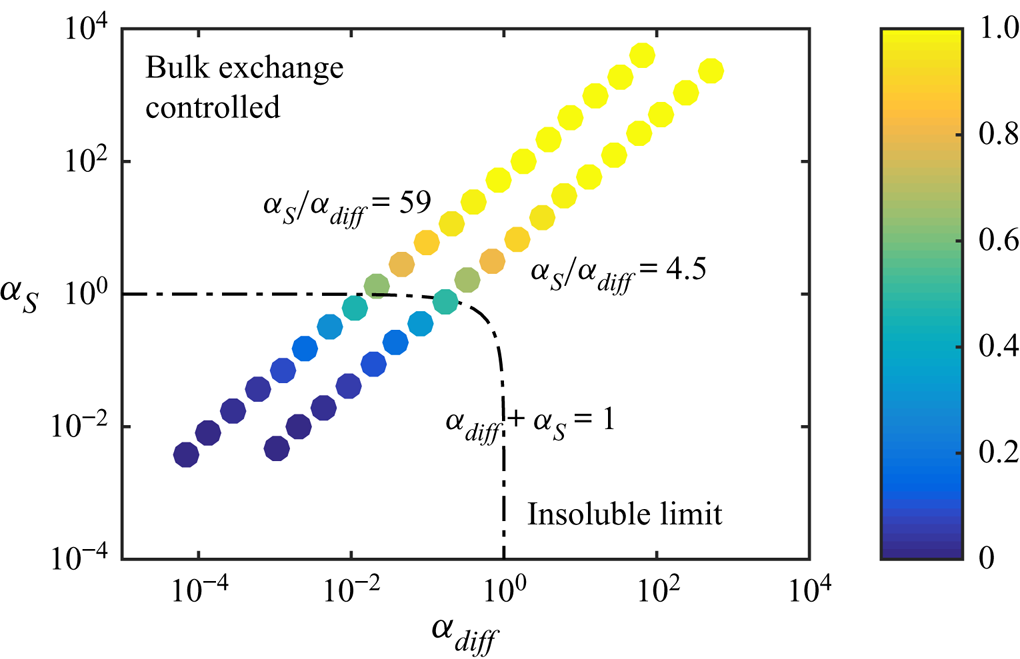

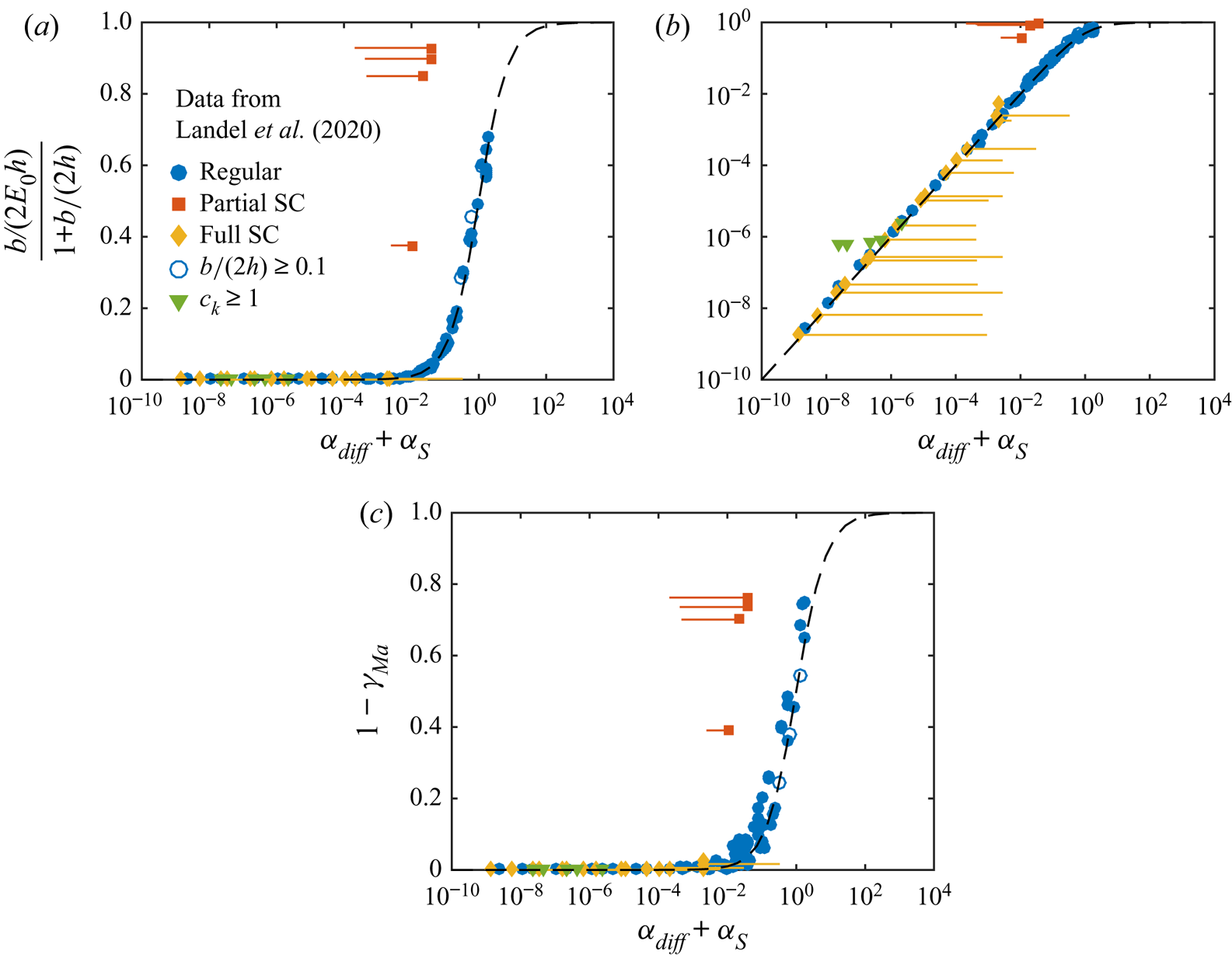

Figure 7 illustrates how ![]() $\alpha _{diff}$ and

$\alpha _{diff}$ and ![]() $\alpha _S$ can be used to predict whether there will be a considerable decrease in slip length. These two parameters span a two-dimensional space. If

$\alpha _S$ can be used to predict whether there will be a considerable decrease in slip length. These two parameters span a two-dimensional space. If

the slip length has halved compared with surfactant-free interfaces (![]() $b/(b_{SHS}\beta _{LIS}) \approx 0.5$). In the region bounded by (5.20), the slip length decrease is larger and outside it is smaller. We use this limit to denote a significant slip length reduction, but other threshold values could also be used. As we only varied

$b/(b_{SHS}\beta _{LIS}) \approx 0.5$). In the region bounded by (5.20), the slip length decrease is larger and outside it is smaller. We use this limit to denote a significant slip length reduction, but other threshold values could also be used. As we only varied ![]() $c_0$,

$c_0$, ![]() $\alpha _S/\alpha _{diff}$ is constant, describing a straight line in the

$\alpha _S/\alpha _{diff}$ is constant, describing a straight line in the ![]() $(\alpha _{diff},\alpha _S)$ space, shown in figure 7 for the water–air and the

$(\alpha _{diff},\alpha _S)$ space, shown in figure 7 for the water–air and the ![]() $\kappa _d = 5\,{\rm s}^{-1}$ water–dodecane systems (cf. figure 5). The water–dodecane system has

$\kappa _d = 5\,{\rm s}^{-1}$ water–dodecane systems (cf. figure 5). The water–dodecane system has ![]() $\alpha _S$ and

$\alpha _S$ and ![]() $\alpha _{diff}$ of similar magnitude (

$\alpha _{diff}$ of similar magnitude (![]() $\alpha _S/\alpha _{diff} = 4.5$). Bulk exchange is more prominent than interfacial diffusion, but both are considerable. For the air–water system, bulk exchange dominates and the points are shifted towards the upper left corner of the figure.

$\alpha _S/\alpha _{diff} = 4.5$). Bulk exchange is more prominent than interfacial diffusion, but both are considerable. For the air–water system, bulk exchange dominates and the points are shifted towards the upper left corner of the figure.

Figure 7. Normalised slip length ![]() $b/(b_{SHS}\beta _{LIS})$ of the SDS water–air and the SDS

$b/(b_{SHS}\beta _{LIS})$ of the SDS water–air and the SDS ![]() $\kappa _d = 5\,{\rm s}^{-1}$ water–dodecane systems (

$\kappa _d = 5\,{\rm s}^{-1}$ water–dodecane systems (![]() $\alpha _S/\alpha _{diff} = 59$ and

$\alpha _S/\alpha _{diff} = 59$ and ![]() $4.5$, respectively), plotted in the space spanned by

$4.5$, respectively), plotted in the space spanned by ![]() $\alpha _{diff}$ and

$\alpha _{diff}$ and ![]() $\alpha _S$. The dash-dotted line shows

$\alpha _S$. The dash-dotted line shows ![]() $\alpha _{diff} + \alpha _S = 1$.

$\alpha _{diff} + \alpha _S = 1$.

6. Adsorption and desorption taking into account alkane–surfactant interaction

The bulk exchange model presented in § 4 resulted in a more considerable surface tension decrease for the LIS than the SHS for the same SDS concentration. However, it cannot capture the initial decrease in surface tension at low concentrations appearing in water–alkane systems. To be able to describe this phenomenon, more advanced models are needed.

The water–alkane interface abnormalities must be caused by interactions between adsorbed surfactants and alkane molecules adjacent to the interface. The level of interaction between adsorbed surfactant and alkane molecules at the interface can be modelled by an effective alkane interface concentration ![]() $\varGamma ^a$ (Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). It is associated with a molar area

$\varGamma ^a$ (Fainerman et al. Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). It is associated with a molar area ![]() $\omega ^a \sim \omega$ and surface coverage

$\omega ^a \sim \omega$ and surface coverage ![]() $\theta ^a = \omega ^a\varGamma ^a$. This interaction has recently been investigated on molecular levels (Kartashynska et al. Reference Kartashynska, Lylyk, Aksenenko, Makievski, Vysotsky, Fainerman and Miller2020; Müller et al. Reference Müller, Bonthuis, Miller and Schneck2021). In this paper, we adopt a model consistent with the equilibrium model of Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). They assumed that the molar area

$\theta ^a = \omega ^a\varGamma ^a$. This interaction has recently been investigated on molecular levels (Kartashynska et al. Reference Kartashynska, Lylyk, Aksenenko, Makievski, Vysotsky, Fainerman and Miller2020; Müller et al. Reference Müller, Bonthuis, Miller and Schneck2021). In this paper, we adopt a model consistent with the equilibrium model of Fainerman et al. (Reference Fainerman, Aksenenko, Makievski, Nikolenko, Javadi, Schneck and Miller2019). They assumed that the molar area ![]() $\omega$ decreased with surface coverage. However, this decrease is only notable for higher concentrations (

$\omega$ decreased with surface coverage. However, this decrease is only notable for higher concentrations (![]() $\theta \sim 1$), and, therefore, we neglect this correction.

$\theta \sim 1$), and, therefore, we neglect this correction.

The interfacial and bulk surfactant concentrations are assumed to follow the same transport equations as the previous model ((2.4) and (2.5), respectively). However, the source term is (cf. (4.1))

where we have introduced the additional interaction constant ![]() $a^{as}$ and the total surface coverage

$a^{as}$ and the total surface coverage ![]() $\theta ^t = \theta + \theta ^a$. The adsorption term contains the total surface coverage, but the desorption term maintains its

$\theta ^t = \theta + \theta ^a$. The adsorption term contains the total surface coverage, but the desorption term maintains its ![]() $\theta$-dependency (together with an additional exponential factor).

$\theta$-dependency (together with an additional exponential factor).

We assume that the alkane molecules are in local equilibrium with the adsorbed surfactants, resulting in the corresponding expression

where ![]() $\kappa _a^a$ and

$\kappa _a^a$ and ![]() $\kappa _d^a$ are the adsorption and desorption coefficients of the alkane phase, respectively,

$\kappa _d^a$ are the adsorption and desorption coefficients of the alkane phase, respectively, ![]() $a^a$ is a constant and

$a^a$ is a constant and ![]() $c_0^a$ is the (constant) bulk alkane concentration. The current model assumes that the alkane adsorption coefficient depends on

$c_0^a$ is the (constant) bulk alkane concentration. The current model assumes that the alkane adsorption coefficient depends on ![]() $\theta$ by

$\theta$ by

where ![]() $\kappa _{a,0}^{a}$ and

$\kappa _{a,0}^{a}$ and ![]() $\kappa _{a,{max}}^a$ are constants. This expression implies that the alkane adsorption rate increases proportionally to

$\kappa _{a,{max}}^a$ are constants. This expression implies that the alkane adsorption rate increases proportionally to ![]() $\theta$ for minuscule concentrations. Without surfactants,

$\theta$ for minuscule concentrations. Without surfactants, ![]() $\theta ^a = 0$.

$\theta ^a = 0$.

The surface tension has been modelled by (cf. (4.2))

where

is the effective average molar area.

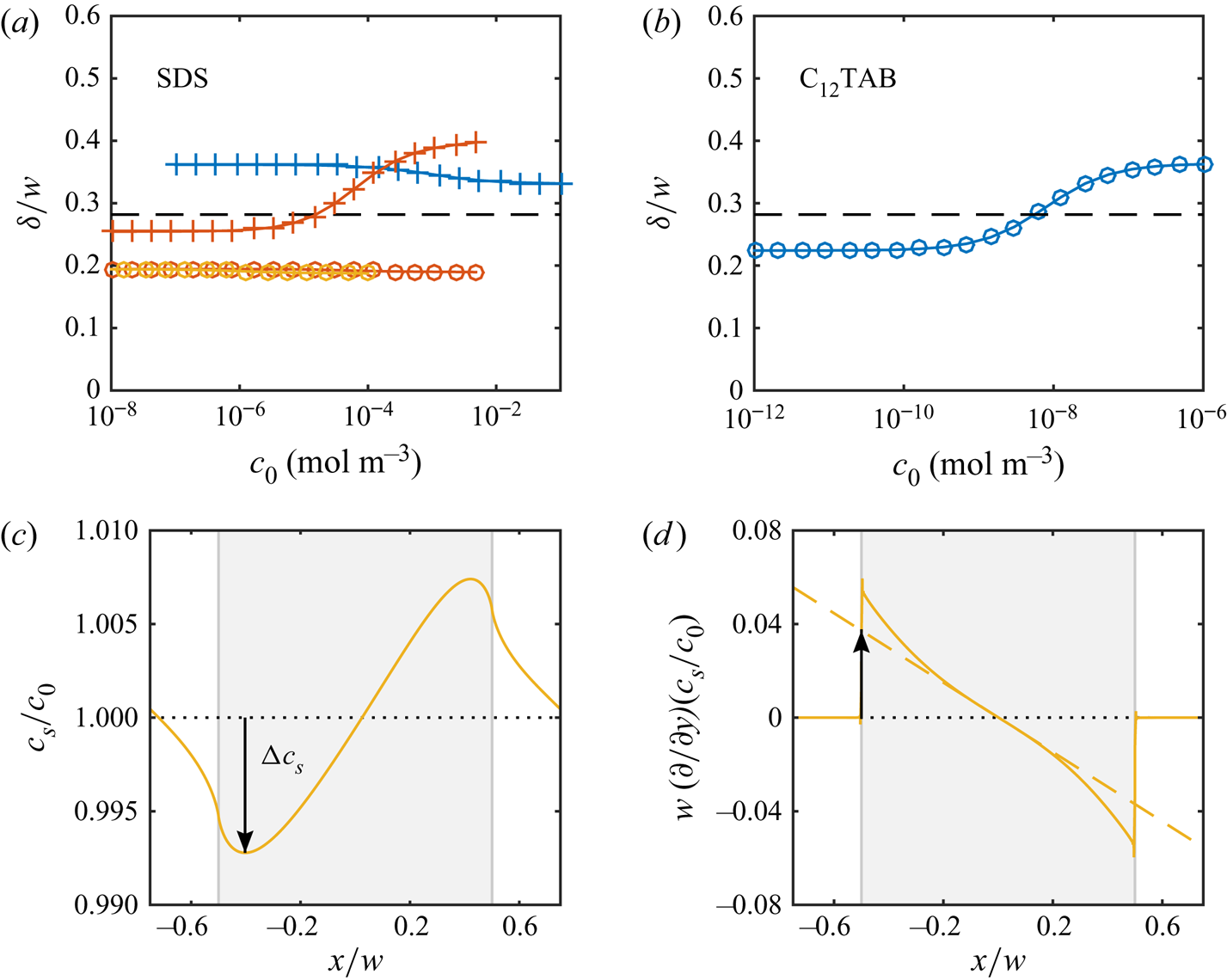

The results plotted in figure 5 show that this improved modelling lowers the critical concentration by an additional order of magnitude. Corresponding results for C![]() $_{12}$TAB and water–hexane LIS are shown in figure 8. We only used the more advanced adsorption/desorption model for C

$_{12}$TAB and water–hexane LIS are shown in figure 8. We only used the more advanced adsorption/desorption model for C![]() $_{12}$TAB (parameters given in table 1). This system manifests a stronger sensitivity to the surfactants, as

$_{12}$TAB (parameters given in table 1). This system manifests a stronger sensitivity to the surfactants, as ![]() $b/p$ decreases significantly at even lower concentrations. The simulations are illustrated in the

$b/p$ decreases significantly at even lower concentrations. The simulations are illustrated in the ![]() $(\alpha _{diff},\alpha _S)$ space in figure 8(c). In contrast to SDS (figure 7), C

$(\alpha _{diff},\alpha _S)$ space in figure 8(c). In contrast to SDS (figure 7), C![]() $_{12}$TAB have more prominent interfacial diffusion than bulk exchange (

$_{12}$TAB have more prominent interfacial diffusion than bulk exchange (![]() $\alpha _S/\alpha _{diff} = 0.30$). Therefore, the simulations are closer to the bottom right corner of the figure.

$\alpha _S/\alpha _{diff} = 0.30$). Therefore, the simulations are closer to the bottom right corner of the figure.

Figure 8. (a) Equilibrium surface tension of C![]() $_{12}$TAB at a water–hexane interface with experimental data from Pradines et al. (Reference Pradines, Fainerman, Aksenenko, Krägel, Mucic and Miller2010). Without surfactants, the surface tension is

$_{12}$TAB at a water–hexane interface with experimental data from Pradines et al. (Reference Pradines, Fainerman, Aksenenko, Krägel, Mucic and Miller2010). Without surfactants, the surface tension is ![]() $\gamma _c = 50.8\,{\rm mN}\,{\rm m}^{-1}$ for water–hexane (

$\gamma _c = 50.8\,{\rm mN}\,{\rm m}^{-1}$ for water–hexane (![]() $20\,^{\circ }{\rm C}$, Zeppieri et al. Reference Zeppieri, Rodríguez and López de Ramos2001). (b) Slip lengths at

$20\,^{\circ }{\rm C}$, Zeppieri et al. Reference Zeppieri, Rodríguez and López de Ramos2001). (b) Slip lengths at ![]() $\tau _\infty = 0.33$ mPa for different bulk concentrations of C

$\tau _\infty = 0.33$ mPa for different bulk concentrations of C![]() $_{12}$TAB at a water–hexane interface, together with the analytical model (dashed lines). The correspondence for SDS is shown in figure 5(a). (c) Normalised slip length,

$_{12}$TAB at a water–hexane interface, together with the analytical model (dashed lines). The correspondence for SDS is shown in figure 5(a). (c) Normalised slip length, ![]() $b/(b_{SHS}\beta _{LIS})$, plotted in the parameter space of

$b/(b_{SHS}\beta _{LIS})$, plotted in the parameter space of ![]() $\alpha _{diff}$ and

$\alpha _{diff}$ and ![]() $\alpha _S$. In both (b,c), the dashed-dotted lines are

$\alpha _S$. In both (b,c), the dashed-dotted lines are ![]() $\alpha _{diff} + \alpha _S = 1$, corresponding to

$\alpha _{diff} + \alpha _S = 1$, corresponding to ![]() $b/(b_{SHS}\beta _{LIS}) \approx 1/2$ (5.16).

$b/(b_{SHS}\beta _{LIS}) \approx 1/2$ (5.16).

6.1. Analytical model with alkane–surfactant interaction

Even if the source term has been changed slightly, the analytical model developed in § 5 is essentially the same. The linear approximation of (6.1) is equal to (5.2). With the surfactant transport equations unchanged, the bulk exchange and the interfacial transport predictions do not need to be modified (§§ 5.1 and 5.2, respectively).

By linearising the alkane source term (6.2), an estimation of ![]() $\theta ^a$ can be found. We introduce the non-dimensional alkane concentrations

$\theta ^a$ can be found. We introduce the non-dimensional alkane concentrations ![]() $c_{k,0}^a = c_0^a\kappa _0^a/\kappa _{d}^a$ and

$c_{k,0}^a = c_0^a\kappa _0^a/\kappa _{d}^a$ and ![]() $c_{k,{max}}^a = c_0^a\kappa _{a,{max}}^a/\kappa _{d}^a$. For large concentrations,

$c_{k,{max}}^a = c_0^a\kappa _{a,{max}}^a/\kappa _{d}^a$. For large concentrations, ![]() $\theta ^a \approx c_{k,{max}}^a$, whereas for small concentrations,

$\theta ^a \approx c_{k,{max}}^a$, whereas for small concentrations, ![]() $\theta ^a \approx c_{k,0}^a\theta \approx c_{k,0}^a c_k$ (6.3). Capturing both cases,

$\theta ^a \approx c_{k,0}^a\theta \approx c_{k,0}^a c_k$ (6.3). Capturing both cases,

All simulations have resulted in values in the lower concentration interval (![]() $c_{k,0}^a \theta \le c_{k,{max}}^a$). It follows that

$c_{k,0}^a \theta \le c_{k,{max}}^a$). It follows that ![]() $\Delta \theta \approx \Delta \theta ^a/c_{k,0}^a$.

$\Delta \theta \approx \Delta \theta ^a/c_{k,0}^a$.

We use the linear approximation of the surface tension (6.4) to estimate the Marangoni stresses. With ![]() $c_{k,0}^a > 1$ (table 1),

$c_{k,0}^a > 1$ (table 1), ![]() $\theta ^a$ is assumed to be larger than

$\theta ^a$ is assumed to be larger than ![]() $\theta$ at low concentrations (6.6). With

$\theta$ at low concentrations (6.6). With ![]() $\omega _0 \approx \omega ^a$,

$\omega _0 \approx \omega ^a$,

where ![]() ${ {Ma}}^a = RT/(\omega ^a \mu _\infty U)$ (cf. (5.12)). Analogous to (5.13),

${ {Ma}}^a = RT/(\omega ^a \mu _\infty U)$ (cf. (5.12)). Analogous to (5.13), ![]() $\mathrm {d} \theta ^a/\mathrm {d}\kern 0.06em x \approx 2\Delta \theta ^a/w \approx 2c_{k,0}^a\Delta \theta /w$, giving

$\mathrm {d} \theta ^a/\mathrm {d}\kern 0.06em x \approx 2\Delta \theta ^a/w \approx 2c_{k,0}^a\Delta \theta /w$, giving

We now adapt the estimation of the slip length (5.16). Equations (3.5), (5.10) and (6.8) give an expression for ![]() $\Delta \theta$ corresponding to (5.15). The slip length is found from (3.2) and is identical to (5.16) if

$\Delta \theta$ corresponding to (5.15). The slip length is found from (3.2) and is identical to (5.16) if ![]() ${ {Ma}}$ is replaced by

${ {Ma}}$ is replaced by ![]() ${ {Ma}}^ac_{k,0}^a$, equivalent to redefining

${ {Ma}}^ac_{k,0}^a$, equivalent to redefining

The results from this analytical model are also shown in figures 5 and 8(b), in good agreement with the simulation results.

The sudden change in the gradient of ![]() $\gamma$ in figures 4 and 8(a) (

$\gamma$ in figures 4 and 8(a) (![]() $c_s = 1.1\times 10^{-2}$ and

$c_s = 1.1\times 10^{-2}$ and ![]() $1.6\times 10^{-4}\,{\rm mol}\,{\rm m}^{-3}$, respectively) coincide with switching the