Article contents

Hydrodynamic force and torque acting on a micron-sized spherical particle attached to a surface with large-scale concave roughness in linear shear flow and the possibility of detachment

Published online by Cambridge University Press: 24 August 2022

Abstract

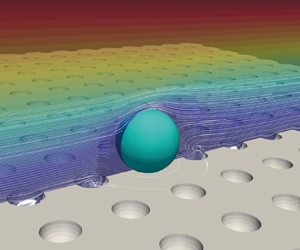

This work studies the detachment of a micron-sized spherical particle from a surface with concave roughness in a linear shear flow. The concave roughness is described as regularly spaced hollow hemispheres below a flat surface and is characterised by two dimensionless parameters, i.e. dimensionless asperity distance and asperity size ratio. The hydrodynamic force and torque on the particle are calculated by performing lattice Boltzmann simulations for particle Reynolds numbers ranging from 0.02 to 40. Empirical correlations of the drag, lift and torque coefficients of the particle as functions of the particle Reynolds number and the asperity size ratio are proposed. For detachment by lifting, sliding and rolling, a numerical approach to calculate the critical particle Reynolds number (i.e. above which the particle can detach from the surface) is proposed. It is found that the dimensionless asperity distance and the distribution of asperities on the rough surface have a minor influence on the hydrodynamic force and torque on the particle, and the detachment of the particle becomes more difficult as the particle sits deeper in a larger hole. Both the empirical correlations and the numerical approach can be implemented into Lagrangian particle tracking and can accurately predict the detachment of particles from the surface with concave roughness or the detachment of particles embedded in a flat surface.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

REFERENCES

- 1

- Cited by