1. Introduction

Surface-tension-driven instability of liquid jets and their subsequent disintegration into droplets has been much investigated since the pioneering work of Plateau (Reference Plateau1873) and Rayleigh (Reference Rayleigh1878, Reference Rayleigh1892). This instability also plays an important role in the dynamics of a liquid film coated on a fibre with additional complexities introduced by liquid–solid interfaces, which has received considerable scientific interest (Quéré Reference Quéré1999) because it is crucial to a range of technologies such as optical fibre manufacturing (Deng et al. Reference Deng, Nave, Liang, Johnson and Fink2011), droplet transport (Lee et al. Reference Lee, Chan, Carlson and Dalnoki-Veress2022) and water collection through fog harvesting (Chen et al. Reference Chen, Ran, Gan, Zhou, Zhang, Zhang, Zhang and Jiang2018; Zhang et al. Reference Zhang, Zheng, Zhu, Zhu, Si and Xu2022).

The Rayleigh–Plateau (RP) instability analysis for annular films was first performed by Goren (Reference Goren1962), who showed that a film of outer radius ![]() $h_0$ is unstable to sufficiently long wavelength disturbances

$h_0$ is unstable to sufficiently long wavelength disturbances ![]() $\lambda > \lambda _{crit} = 2 {\rm \pi}h_0$ (where

$\lambda > \lambda _{crit} = 2 {\rm \pi}h_0$ (where ![]() $\lambda _{crit}$ is the critical wavelength of the instability beyond which no growth of the instability occurs), and dominant (the most unstable/fast growing) modes depend on the ratio of

$\lambda _{crit}$ is the critical wavelength of the instability beyond which no growth of the instability occurs), and dominant (the most unstable/fast growing) modes depend on the ratio of ![]() $h_0$ to the fibre radius

$h_0$ to the fibre radius ![]() $a$, confirmed by experiments (Goren Reference Goren1964). Hammond (Reference Hammond1983) found the same instability of a thin film inside a capillary tube with a nonlinear analysis for the appearance and growth of periodically spaced lobes. Under the lubrication approximation that the film thickness is much smaller than the fibre radius (i.e.

$a$, confirmed by experiments (Goren Reference Goren1964). Hammond (Reference Hammond1983) found the same instability of a thin film inside a capillary tube with a nonlinear analysis for the appearance and growth of periodically spaced lobes. Under the lubrication approximation that the film thickness is much smaller than the fibre radius (i.e. ![]() $h_0-a \ll a$), Frenkel (Reference Frenkel1992) proposed a weakly nonlinear thin-film equation. Because of its simplicity and capability of predicting nonlinear behaviours, this lubrication equation and its higher-order versions (Craster & Matar Reference Craster and Matar2006; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) have been used widely to study thin-film dynamics flowing down a fibre theoretically (Kalliadasis & Chang Reference Kalliadasis and Chang1994; Yu & Hinch Reference Yu and Hinch2013) and explain experimental findings (Quéré Reference Quéré1990; Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007; Craster & Matar Reference Craster and Matar2009; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019). Recently, these lubrication models have been extended for more complicated situations with other physics taken into account, such as electric fields (Ding et al. Reference Ding, Xie, Wong and Liu2014), heat transfer (Zeng et al. Reference Zeng, Sadeghpour, Warrier and Ju2017), thermal fluctuations (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2021) and van der Waals forces (Tomo, Nag & Takamatsu Reference Tomo, Nag and Takamatsu2022).

$h_0-a \ll a$), Frenkel (Reference Frenkel1992) proposed a weakly nonlinear thin-film equation. Because of its simplicity and capability of predicting nonlinear behaviours, this lubrication equation and its higher-order versions (Craster & Matar Reference Craster and Matar2006; Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) have been used widely to study thin-film dynamics flowing down a fibre theoretically (Kalliadasis & Chang Reference Kalliadasis and Chang1994; Yu & Hinch Reference Yu and Hinch2013) and explain experimental findings (Quéré Reference Quéré1990; Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007; Craster & Matar Reference Craster and Matar2009; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019). Recently, these lubrication models have been extended for more complicated situations with other physics taken into account, such as electric fields (Ding et al. Reference Ding, Xie, Wong and Liu2014), heat transfer (Zeng et al. Reference Zeng, Sadeghpour, Warrier and Ju2017), thermal fluctuations (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2021) and van der Waals forces (Tomo, Nag & Takamatsu Reference Tomo, Nag and Takamatsu2022).

Most of the previous works mentioned employed the classical no-slip boundary condition at the liquid–solid interface, which is inaccurate in some practical cases. For example, silicone oil on a solid wall made of nylon, used in Quéré's experiments (Quéré Reference Quéré1990), has been found to exhibit non-negligible fluid slippage (Brochard-Wyart et al. Reference Brochard-Wyart, De Gennes, Hervert and Redon1994; Lauga, Brenner & Stone Reference Lauga, Brenner and Stone2007). This slip effect has attracted much research attention recently (Secchi et al. Reference Secchi, Marbach, Niguès, Stein, Siria and Bocquet2016; Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2020; Kavokine, Netz & Bocquet Reference Kavokine, Netz and Bocquet2021; Kavokine, Bocquet & Bocquet Reference Kavokine, Bocquet and Bocquet2022) and has been known to be crucial to dynamics of a variety of interfacial flows (Liao et al. Reference Liao, Li, Chang, Huang and Wei2014; Halpern, Li & Wei Reference Halpern, Li and Wei2015; Martínez-Calvo, Moreno-Boza & Sevilla Reference Martínez-Calvo, Moreno-Boza and Sevilla2020; Zhao et al. Reference Zhao, Liu, Lockerby and Sprittles2022). For a cylindrical film, Ding & Liu (Reference Ding and Liu2011) proposed a lubrication equation incorporating slip to explore the instability of a film flowing down a porous vertical fibre. They found that the instability is enhanced by the fluid-porous interface, modelled as a slip boundary condition in the lubrication model. A two-equation lubrication model was then developed for the case at non-infinitesimal Reynolds numbers with inertia taken into account (Ding et al. Reference Ding, Wong, Liu and Liu2013). For an annular film inside a slippery tube, Liao, Li & Wei (Reference Liao, Li and Wei2013) solved numerically a lubrication equation with leading-order terms, and found that the instability is exaggerated by a fractional amount of wall slip, resulting in much more rapid draining compared to the usual no-slip case (Hammond Reference Hammond1983). Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015) investigated experimentally the influence of slip on the RP instability for a film on a horizontal fibre. Similar to the findings of both Ding & Liu (Reference Ding and Liu2011) and Liao et al. (Reference Liao, Li and Wei2013), the instability was found to be enhanced by the wall slip with larger growth rates of undulations obtained. Additionally, these experimental results were shown to match predictions of a slip-modified lubrication equation. Later, Halpern & Wei (Reference Halpern and Wei2017) demonstrated that wall slip can enhance the drop formation in a film flowing down a vertical fibre, providing a plausible interpretation for the discrepancy between the experimentally obtained and theoretically predicted critical Bond numbers for drop formation. More recently, the slippage hydrodynamics of cylindrical films were explored further in a non-isothermal environment (Chao, Ding & Liu Reference Chao, Ding and Liu2018) and under the influence of intermolecular forces (Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) via more complicated lubrication models.

Noticeably, Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001) demonstrated experimentally that the lubrication models for no-slip cases are valid only when the film thickness is smaller than the fibre radius, confirmed by following theoretical analysis performed by Craster & Matar (Reference Craster and Matar2006) based on the Stokes equations. However, when slip is considered, the accuracy of lubrication models for films on a fibre has never been examined carefully, despite its wide usages in theoretical studies (Ding & Liu Reference Ding and Liu2011; Liao et al. Reference Liao, Li and Wei2013; Halpern & Wei Reference Halpern and Wei2017; Chao et al. Reference Chao, Ding and Liu2018) and experimental investigations (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019). In fact, slip-modified lubrication models predict a dominant wavelength independent of slip length, which somehow is not consistent with experimental data (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). Thus it is necessary to provide a more general theoretical analysis to go beyond the lubrication paradigm and clarify the validity of slip-modified lubrication models. For example, it is unclear whether slip-modified lubrication models work for large-slip cases.

In this work, linear stability analysis of the axisymmetric Stokes equations is performed to investigate slip-enhanced RP instability of liquid films on a fibre. Direct numerical simulations of the Navier–Stokes (NS) equations are employed to validate the theoretical findings and provide more physical insights. We also compare our theory with available experimental results (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). The paper is laid out as follows. Non-dimensionalised governing equations for films on fibres are introduced in § 2. In § 3, a theoretical model incorporating slip is developed for the RP instability. Numerical simulations, performed in § 4, are compared with the predictions of the theoretical model for the influence of slip on the growth rate (§ 4.1) and the dominant wavelength (§ 4.2) of perturbations. In § 5, the theoretically predicted dominant wavelengths are compared with the experimental data of Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015).

2. Model formulation

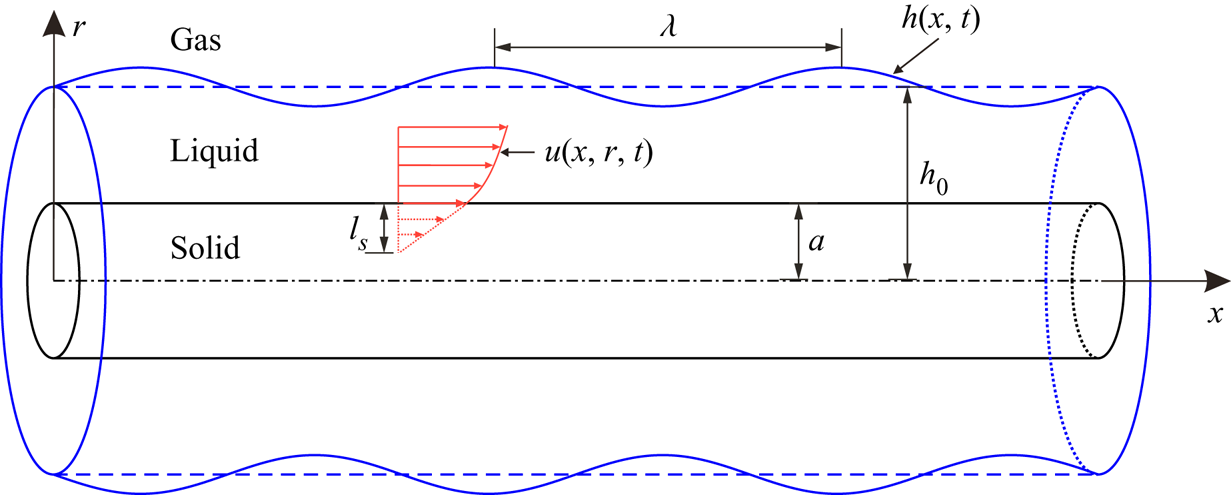

We consider a Newtonian liquid film coating on a horizontal fibre of radius ![]() $a$ with the

$a$ with the ![]() $x$-axis along the centreline (figure 1). The initial radius of the film measured from the

$x$-axis along the centreline (figure 1). The initial radius of the film measured from the ![]() $x$-axis is

$x$-axis is ![]() $r = h_0$.

$r = h_0$.

Figure 1. Schematic of a liquid film on a fibre.

The incompressible NS equations are employed to predict the dynamics of the flow inside the liquid film. To identify the governing dimensionless parameters, we non-dimensionalise the NS equations with the rescaling variables

where ![]() $\tilde {h}$,

$\tilde {h}$, ![]() $\tilde {t}$,

$\tilde {t}$, ![]() $\tilde {\boldsymbol {u}}$ and

$\tilde {\boldsymbol {u}}$ and ![]() $\tilde {p}$ represent the dimensional interface height, time, velocity and pressure, respectively (note that the dimensional material parameters are not given tildes). Also,

$\tilde {p}$ represent the dimensional interface height, time, velocity and pressure, respectively (note that the dimensional material parameters are not given tildes). Also, ![]() $\tilde {\boldsymbol {\tau }}$ is the shear stress, which is proportional to the strain rate in Newtonian fluids,

$\tilde {\boldsymbol {\tau }}$ is the shear stress, which is proportional to the strain rate in Newtonian fluids, ![]() $\mu$ is the liquid dynamic viscosity, and

$\mu$ is the liquid dynamic viscosity, and ![]() $\gamma$ is the surface tension of the liquid–gas interface. The dimensionless NS equations can be written as

$\gamma$ is the surface tension of the liquid–gas interface. The dimensionless NS equations can be written as

The non-dimensional quantity ![]() ${Oh}=\mu /\sqrt {\rho \gamma h_0}$ is the Ohnesorge number, which relates the viscous forces to inertial and surface-tension forces. Note that in the previous experiment for the slip-enhanced RP instability (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015), a high-viscosity polymer liquid, entangled polystyrene, is coated on a fibre with radius

${Oh}=\mu /\sqrt {\rho \gamma h_0}$ is the Ohnesorge number, which relates the viscous forces to inertial and surface-tension forces. Note that in the previous experiment for the slip-enhanced RP instability (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015), a high-viscosity polymer liquid, entangled polystyrene, is coated on a fibre with radius ![]() $10\unicode{x2013}25\ \mathrm {\mu }\mathrm {m}$. The density of the entangled polystyrene is

$10\unicode{x2013}25\ \mathrm {\mu }\mathrm {m}$. The density of the entangled polystyrene is ![]() $\rho =1.05\ \mathrm {g}\ \mathrm {cm}^{-3}$, and its liquid–gas surface tension is

$\rho =1.05\ \mathrm {g}\ \mathrm {cm}^{-3}$, and its liquid–gas surface tension is ![]() $\gamma = 30.8\ \mathrm {mN}\ \mathrm {m}^{-1}$. The liquid viscosity depends on temperature, with various values in the range

$\gamma = 30.8\ \mathrm {mN}\ \mathrm {m}^{-1}$. The liquid viscosity depends on temperature, with various values in the range ![]() $0.2\unicode{x2013}10\ \mathrm{kg}\ \mathrm {m}^{-1}\ \mathrm {s}^{-1}$ (Haefner Reference Haefner2015). So the Ohnesorge number of liquid film in the experiment is larger than 10, and

$0.2\unicode{x2013}10\ \mathrm{kg}\ \mathrm {m}^{-1}\ \mathrm {s}^{-1}$ (Haefner Reference Haefner2015). So the Ohnesorge number of liquid film in the experiment is larger than 10, and ![]() ${Oh}^2 \gg 1$ in (2.3). It is reasonable to assume that the inertial terms are negligible compared to the viscous terms. With axisymmetric initial perturbations, (2.2) and (2.3) can be reduced to axisymmetric Stokes equations, written as

${Oh}^2 \gg 1$ in (2.3). It is reasonable to assume that the inertial terms are negligible compared to the viscous terms. With axisymmetric initial perturbations, (2.2) and (2.3) can be reduced to axisymmetric Stokes equations, written as

where ![]() $u$ and

$u$ and ![]() $v$ represent the axial and radial velocities, respectively. Since the density of gas around the film is much smaller than that of liquid, the gas flow outside can be assumed to be dynamically passive to simplify the problem. The liquid–gas interface height

$v$ represent the axial and radial velocities, respectively. Since the density of gas around the film is much smaller than that of liquid, the gas flow outside can be assumed to be dynamically passive to simplify the problem. The liquid–gas interface height ![]() $h(x,t)$ satisfies the kinematic boundary condition

$h(x,t)$ satisfies the kinematic boundary condition

The normal stress balances at the interface ![]() $r=h$ give

$r=h$ give

where ![]() $\boldsymbol {n}$ is the outward normal, and

$\boldsymbol {n}$ is the outward normal, and ![]() $\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {n}$ represents the dimensionless Laplace pressure. The tangential force balance is

$\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {n}$ represents the dimensionless Laplace pressure. The tangential force balance is

where ![]() $\boldsymbol {t}$ is the tangential vector. With

$\boldsymbol {t}$ is the tangential vector. With ![]() $\boldsymbol {n}$ and

$\boldsymbol {n}$ and ![]() $\boldsymbol {t}$ expressed in terms of the unit vectors in the

$\boldsymbol {t}$ expressed in terms of the unit vectors in the ![]() $x$-direction (

$x$-direction (![]() $\hat {\boldsymbol {e}}_x$) and

$\hat {\boldsymbol {e}}_x$) and ![]() $r$-direction (

$r$-direction (![]() $\hat {\boldsymbol {e}}_r$), i.e.

$\hat {\boldsymbol {e}}_r$), i.e.

(2.8) and (2.9) give explicitly

\begin{align} &p - \frac{2}{1+ \left(\partial_x h \right)^2} \left[ \frac{\partial v}{\partial r} - \frac{\partial h}{\partial x} \left( \frac{\partial u}{\partial r} + \frac{\partial v}{\partial x}\right) + \left(\frac{\partial h}{\partial x} \right)^2 \frac{\partial u}{\partial x} \right] \nonumber\\ &\quad =\frac{1}{h \sqrt{1+\left(\partial_x h \right)^2}} - \frac{\partial_x^2 h}{\left(1+\left(\partial_x h \right)^2\right) ^{3/2}} \end{align}

\begin{align} &p - \frac{2}{1+ \left(\partial_x h \right)^2} \left[ \frac{\partial v}{\partial r} - \frac{\partial h}{\partial x} \left( \frac{\partial u}{\partial r} + \frac{\partial v}{\partial x}\right) + \left(\frac{\partial h}{\partial x} \right)^2 \frac{\partial u}{\partial x} \right] \nonumber\\ &\quad =\frac{1}{h \sqrt{1+\left(\partial_x h \right)^2}} - \frac{\partial_x^2 h}{\left(1+\left(\partial_x h \right)^2\right) ^{3/2}} \end{align}for the normal forces, and

\begin{equation} 2\,\frac{\partial h}{\partial x} \left( \frac{\partial v}{\partial r} - \frac{\partial u}{\partial x} \right) + \left[ 1- \left(\frac{\partial h}{\partial x} \right)^2 \right] \left( \frac{\partial u}{\partial r} + \frac{\partial v}{\partial x} \right) = 0 \end{equation}

\begin{equation} 2\,\frac{\partial h}{\partial x} \left( \frac{\partial v}{\partial r} - \frac{\partial u}{\partial x} \right) + \left[ 1- \left(\frac{\partial h}{\partial x} \right)^2 \right] \left( \frac{\partial u}{\partial r} + \frac{\partial v}{\partial x} \right) = 0 \end{equation}

for the tangential forces. Here, ![]() $\partial _x$ and

$\partial _x$ and ![]() $\partial _x^2$ refer to first and second spatial derivatives. In terms of the boundary conditions at the fibre surface

$\partial _x^2$ refer to first and second spatial derivatives. In terms of the boundary conditions at the fibre surface ![]() $r = \alpha$ (where

$r = \alpha$ (where ![]() $\alpha$ is the dimensionless fibre radius, i.e.

$\alpha$ is the dimensionless fibre radius, i.e. ![]() $\alpha = a/h_0$), we have the slip boundary condition in the tangential direction and the no-penetration boundary condition in the normal direction, such that

$\alpha = a/h_0$), we have the slip boundary condition in the tangential direction and the no-penetration boundary condition in the normal direction, such that

Here, ![]() $l_{s}$ represents the dimensionless slip length rescaled by

$l_{s}$ represents the dimensionless slip length rescaled by ![]() $h_0$. The governing equations above can be simplified further under the long-wave approximation to give a one-dimensional lubrication equation, compared with experimental results in the previous work (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). This lubrication equation is displayed here for the instability analysis appearing in § 3 (see Appendix A for the derivation). Its dimensionless format is

$h_0$. The governing equations above can be simplified further under the long-wave approximation to give a one-dimensional lubrication equation, compared with experimental results in the previous work (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). This lubrication equation is displayed here for the instability analysis appearing in § 3 (see Appendix A for the derivation). Its dimensionless format is

where ![]() $M(h)$ is the mobility term

$M(h)$ is the mobility term

and ![]() $p$ is the Laplace pressure

$p$ is the Laplace pressure

3. Instability analysis

In this section, linear instability analysis based on (2.4)–(2.13a,b) is performed using the normal mode method, which has been used widely for the RP instability in different fluid configurations (Rayleigh Reference Rayleigh1878; Tomotika Reference Tomotika1935; Craster & Matar Reference Craster and Matar2006; Liang et al. Reference Liang, Deng, Nave and Johnson2011). The dimensionless perturbed quantities are expressed as

\begin{equation} \left.\begin{gathered} u(x,r,t) = \hat{u}(r) \exp({\omega t+{\rm i}kx}),\quad v(x,r,t) = \hat{v}(r) \exp({\omega t+{\rm i}kx})\\ \textrm{and}\quad p(x,r,t) = 1 + \hat{p}(r) \exp({\omega t+{\rm i}kx}), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} u(x,r,t) = \hat{u}(r) \exp({\omega t+{\rm i}kx}),\quad v(x,r,t) = \hat{v}(r) \exp({\omega t+{\rm i}kx})\\ \textrm{and}\quad p(x,r,t) = 1 + \hat{p}(r) \exp({\omega t+{\rm i}kx}), \end{gathered}\right\} \end{equation}

where ![]() $\omega$ is the growth rate of perturbations, and

$\omega$ is the growth rate of perturbations, and ![]() $k$ is the wavenumber. Substituting these quantities into the mass and momentum equations (2.4)–(2.6) leads to

$k$ is the wavenumber. Substituting these quantities into the mass and momentum equations (2.4)–(2.6) leads to

With (3.2)–(3.4), we can eliminate ![]() $\hat {u}$ and

$\hat {u}$ and ![]() $\hat {p}$ to get a fourth-order ordinary partial differential equation for

$\hat {p}$ to get a fourth-order ordinary partial differential equation for ![]() $\hat {v}$:

$\hat {v}$:

The general solution for (3.5) can be obtained in terms of Bessel functions, written as

where I and K are modified Bessel function of the first and second kinds, the subscripts ![]() $0$ and

$0$ and ![]() $1$ represent the order of the Bessel functions,

$1$ represent the order of the Bessel functions, ![]() $C_1\unicode{x2013} C_4$ are four arbitrary constants to be determined by the boundary conditions, and

$C_1\unicode{x2013} C_4$ are four arbitrary constants to be determined by the boundary conditions, and ![]() $r\in [\alpha,1]$. Substituting (3.6) into (3.2) and (3.3) gives us the solutions for

$r\in [\alpha,1]$. Substituting (3.6) into (3.2) and (3.3) gives us the solutions for ![]() $\hat {u}$ and

$\hat {u}$ and ![]() $\hat {p}$:

$\hat {p}$:

In a similar approach, the dimensionless perturbed quantities for ![]() $\hat {u}, \hat {v}, \hat {p}$, combined with

$\hat {u}, \hat {v}, \hat {p}$, combined with ![]() $h(x,t) = 1 + \hat {h}\exp ({\omega t+\textrm {i}kx})$, are substituted into perturbed boundary equations (2.7)–(2.13a,b). For the boundary conditions at the interface (

$h(x,t) = 1 + \hat {h}\exp ({\omega t+\textrm {i}kx})$, are substituted into perturbed boundary equations (2.7)–(2.13a,b). For the boundary conditions at the interface (![]() $r=1$), their linearisation gives

$r=1$), their linearisation gives

And for the boundary conditions on the fibre surface (![]() $r=\alpha$), their linearised forms are

$r=\alpha$), their linearised forms are

According to (3.11), ![]() $\hat {h}$ in (3.10) can be eliminated to give the final four equations of the boundary conditions, i.e. (3.9), (3.10), (3.12) and (3.13). Substituting the Bessel functions (3.6)–(3.8) into these perturbed equations leads to a homogeneous system of linear equations for

$\hat {h}$ in (3.10) can be eliminated to give the final four equations of the boundary conditions, i.e. (3.9), (3.10), (3.12) and (3.13). Substituting the Bessel functions (3.6)–(3.8) into these perturbed equations leads to a homogeneous system of linear equations for ![]() $C_1\unicode{x2013} C_4$, which has a non-trivial solution only if the determinant of the coefficients vanishes. In this way, we have the final equation

$C_1\unicode{x2013} C_4$, which has a non-trivial solution only if the determinant of the coefficients vanishes. In this way, we have the final equation

\begin{equation} \left|\begin{array}{@{}cccc@{}} F_{11} & F_{12} & F_{13} & F_{14} \\ F_{21} & F_{22} & F_{23} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\,{\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \\ \end{array}\right| =0 , \end{equation}

\begin{equation} \left|\begin{array}{@{}cccc@{}} F_{11} & F_{12} & F_{13} & F_{14} \\ F_{21} & F_{22} & F_{23} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\,{\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \\ \end{array}\right| =0 , \end{equation}where

\begin{equation} \left.\begin{gathered} F_{11} = (k^2-1)\,{\rm K}_0(k) - 2 \omega k\,{\rm K}_1(k), \\ F_{12} = (k^2-1)\,{\rm K}_1(k) - 2 \omega \left[ k\,{\rm K}_0(k) + {\rm K}_1(k) \right], \\ F_{13} = (k^2-1)\,{\rm I}_0(k) + 2 \omega k\,{\rm I}_1(k) , \\ F_{14} = (k^2-1)\,{\rm I}_1(k) + 2 \omega \left[ k\,{\rm I}_0(k) - {\rm I}_1(k) \right], \\ F_{21} = (2-l_{s} k^2 \alpha)\,{\rm K}_0(k \alpha) + k(2 l_{s}-\alpha)\,{\rm K}_1(k \alpha) , \\ F_{22} ={-}k\,{\rm K}_0(k \alpha) - l_{s} k^2\,{\rm K}_1(k \alpha), \\ F_{23} = (2-l_{s} k^2 \alpha)\,{\rm I}_0(k \alpha) -k(2 l_{s}-\alpha)\,{\rm I}_1(k \alpha) , \\ F_{24} = k\,{\rm I}_0(k \alpha) - l_{s} k^2\,{\rm I}_1(k \alpha). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} F_{11} = (k^2-1)\,{\rm K}_0(k) - 2 \omega k\,{\rm K}_1(k), \\ F_{12} = (k^2-1)\,{\rm K}_1(k) - 2 \omega \left[ k\,{\rm K}_0(k) + {\rm K}_1(k) \right], \\ F_{13} = (k^2-1)\,{\rm I}_0(k) + 2 \omega k\,{\rm I}_1(k) , \\ F_{14} = (k^2-1)\,{\rm I}_1(k) + 2 \omega \left[ k\,{\rm I}_0(k) - {\rm I}_1(k) \right], \\ F_{21} = (2-l_{s} k^2 \alpha)\,{\rm K}_0(k \alpha) + k(2 l_{s}-\alpha)\,{\rm K}_1(k \alpha) , \\ F_{22} ={-}k\,{\rm K}_0(k \alpha) - l_{s} k^2\,{\rm K}_1(k \alpha), \\ F_{23} = (2-l_{s} k^2 \alpha)\,{\rm I}_0(k \alpha) -k(2 l_{s}-\alpha)\,{\rm I}_1(k \alpha) , \\ F_{24} = k\,{\rm I}_0(k \alpha) - l_{s} k^2\,{\rm I}_1(k \alpha). \end{gathered}\right\} \end{equation}

Because ![]() $\omega$ appears only linearly in the first line of the determinant, the dispersion relation between

$\omega$ appears only linearly in the first line of the determinant, the dispersion relation between ![]() $\omega$ and

$\omega$ and ![]() $k$ can be expressed explicitly as

$k$ can be expressed explicitly as

where

\begin{equation} \left.\begin{gathered} \varDelta_1 = \left|\begin{array}{@{}ccc@{}} F_{22} & F_{23} & F_{24} \\ {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_2 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{23} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\, {\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_3 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{22} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\,{\rm K}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_4 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{22} & F_{23} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\, {\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) \end{array}\right|. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \varDelta_1 = \left|\begin{array}{@{}ccc@{}} F_{22} & F_{23} & F_{24} \\ {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_2 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{23} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & \alpha\,{\rm I}_0(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\, {\rm I}_0(k) + {\rm I}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_3 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{22} & F_{24} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & {\rm I}_1(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\,{\rm K}_1(k) & k\,{\rm I}_1(k) \end{array}\right|, \\ \varDelta_4 = \left|\begin{array}{@{}ccc@{}} F_{21} & F_{22} & F_{23} \\ \alpha\,{\rm K}_0(k \alpha) & {\rm K}_1(k \alpha) & \alpha\,{\rm I}_0(k \alpha) \\ k\,{\rm K}_0(k) - {\rm K}_1(k) & k\, {\rm K}_1(k) & k\,{\rm I}_0(k) + {\rm I}_1(k) \end{array}\right|. \end{gathered}\right\} \end{equation} To compare the Stokes model (3.16) with the lubrication theory, (2.14) is linearised using ![]() $h = 1 + \hat {h} \exp ({\omega t + \textrm {i}kx})$, providing the dispersion relation

$h = 1 + \hat {h} \exp ({\omega t + \textrm {i}kx})$, providing the dispersion relation

where ![]() $M =[3+ \alpha ^4 - 4 \alpha ^2 + 4 \ln \alpha - 4 l_{s} (1-\alpha ^2)^2/\alpha ]/16.$

$M =[3+ \alpha ^4 - 4 \alpha ^2 + 4 \ln \alpha - 4 l_{s} (1-\alpha ^2)^2/\alpha ]/16.$

In figure 2, predictions of (3.16) and (3.18) in the limiting case (![]() $l_{s}=0$) are found to agree with the results of Craster & Matar (Reference Craster and Matar2006). Note that the lubrication dispersion relation (dashed lines) matches the Stokes dispersion relation (solid lines) when

$l_{s}=0$) are found to agree with the results of Craster & Matar (Reference Craster and Matar2006). Note that the lubrication dispersion relation (dashed lines) matches the Stokes dispersion relation (solid lines) when ![]() $\alpha \geqslant 0.6$. However, the agreement deteriorates for the smaller

$\alpha \geqslant 0.6$. However, the agreement deteriorates for the smaller ![]() $\alpha$, mainly due to the limitations of lubrication approximations for ‘thicker’ films. Despite the failure in predicting the dispersion relation for small

$\alpha$, mainly due to the limitations of lubrication approximations for ‘thicker’ films. Despite the failure in predicting the dispersion relation for small ![]() $\alpha$, the Plateau instability criterion with critical wavenumber,

$\alpha$, the Plateau instability criterion with critical wavenumber, ![]() $k_{crit}=2{\rm \pi} h_0/\lambda _{crit}=1$ (Plateau Reference Plateau1873), can be predicted by the lubrication model for all

$k_{crit}=2{\rm \pi} h_0/\lambda _{crit}=1$ (Plateau Reference Plateau1873), can be predicted by the lubrication model for all ![]() $\alpha$ values. The reason is that both the circumferential and tangential curvature for the Laplace pressure are kept in (2.16) to give the term

$\alpha$ values. The reason is that both the circumferential and tangential curvature for the Laplace pressure are kept in (2.16) to give the term ![]() $k^2-1$ in the dispersion relation.

$k^2-1$ in the dispersion relation.

Figure 2. The dispersion relation between the growth rate ![]() $\omega$ and the wavenumber

$\omega$ and the wavenumber ![]() $k$ on the no-slip boundary condition (

$k$ on the no-slip boundary condition (![]() $l_{s}=0$) for various dimensionless fibre radii: (a)

$l_{s}=0$) for various dimensionless fibre radii: (a) ![]() $\alpha =0.7$ (black),

$\alpha =0.7$ (black), ![]() $\alpha =0.6$ (red),

$\alpha =0.6$ (red), ![]() $\alpha =0.5$ (blue); (b)

$\alpha =0.5$ (blue); (b) ![]() $\alpha =0.3$ (black),

$\alpha =0.3$ (black), ![]() $\alpha =0.2$ (red),

$\alpha =0.2$ (red), ![]() $\alpha =0.1$ (blue). The predictions of the Stokes model (3.16) are plotted in solid lines, and results from the lubrication model (3.18) are illustrated in dashed lines. The triangles and circles are the long-wave and Stokes results of Craster & Matar (Reference Craster and Matar2006), employed here to verify (3.16) and (3.18), respectively.

$\alpha =0.1$ (blue). The predictions of the Stokes model (3.16) are plotted in solid lines, and results from the lubrication model (3.18) are illustrated in dashed lines. The triangles and circles are the long-wave and Stokes results of Craster & Matar (Reference Craster and Matar2006), employed here to verify (3.16) and (3.18), respectively.

Figure 3 illustrates the dispersion relations of different ![]() $l_{s}$ values. Both the Stokes model and the lubrication model show that the RP instability is enhanced by slip with faster growing perturbations for larger

$l_{s}$ values. Both the Stokes model and the lubrication model show that the RP instability is enhanced by slip with faster growing perturbations for larger ![]() $l_{s}$, consistent with previous findings based on lubrication models (Liao et al. Reference Liao, Li and Wei2013; Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Halpern & Wei Reference Halpern and Wei2017). However, obvious discrepancies between the Stokes dispersion relation and the lubrication dispersion relation are found in most cases in figure 3. Even for thin films (

$l_{s}$, consistent with previous findings based on lubrication models (Liao et al. Reference Liao, Li and Wei2013; Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Halpern & Wei Reference Halpern and Wei2017). However, obvious discrepancies between the Stokes dispersion relation and the lubrication dispersion relation are found in most cases in figure 3. Even for thin films (![]() $\alpha \geqslant 0.7$), where the lubrication model has been shown to perform well on the no-slip boundary condition (see the agreement of black lines in figures 3a,b), remarkable discrepancies appear when

$\alpha \geqslant 0.7$), where the lubrication model has been shown to perform well on the no-slip boundary condition (see the agreement of black lines in figures 3a,b), remarkable discrepancies appear when ![]() $l_{s} \geqslant 0.5$, indicating that the lubrication model (2.14) is not suitable for large-slip cases. The main reason is that the lubrication approximation imposes a restriction on

$l_{s} \geqslant 0.5$, indicating that the lubrication model (2.14) is not suitable for large-slip cases. The main reason is that the lubrication approximation imposes a restriction on ![]() $l_{s}$, namely

$l_{s}$, namely ![]() $l_{s} \ll \lambda ^2 -1+\alpha$, where

$l_{s} \ll \lambda ^2 -1+\alpha$, where ![]() $\lambda$ is the perturbation wavelength (see the derivation of (A30) and its corresponding explanation in Appendix A). Moreover, the discrepancy increases for larger

$\lambda$ is the perturbation wavelength (see the derivation of (A30) and its corresponding explanation in Appendix A). Moreover, the discrepancy increases for larger ![]() $\alpha$, similar to the trend found in the no-slip cases in figure 2.

$\alpha$, similar to the trend found in the no-slip cases in figure 2.

Figure 3. The dispersion relation between the growth rate ![]() $\omega$ and the wavenumber

$\omega$ and the wavenumber ![]() $k$ on different boundary conditions of various dimensionless fibre radii: (a)

$k$ on different boundary conditions of various dimensionless fibre radii: (a) ![]() $\alpha =0.9$, (b)

$\alpha =0.9$, (b) ![]() $\alpha =0.7$, (c)

$\alpha =0.7$, (c) ![]() $\alpha =0.5$, (d)

$\alpha =0.5$, (d) ![]() $\alpha =0.3$. The solid and dashed lines are the predictions of the Stokes model (3.16) and the lubrication model (3.18), respectively, on three boundary conditions with

$\alpha =0.3$. The solid and dashed lines are the predictions of the Stokes model (3.16) and the lubrication model (3.18), respectively, on three boundary conditions with ![]() $l_{s}=0$ (black),

$l_{s}=0$ (black), ![]() $l_{s}=0.25$ (blue) and

$l_{s}=0.25$ (blue) and ![]() $l_{s}=0.5$ (red).

$l_{s}=0.5$ (red).

The ![]() $k_{crit}$ values for the RP instability in figure 3 are found to be not affected by the slip. These values are determined by the competition between the two curvature terms for the Laplace pressure, shown on the right-hand side of (2.11), where the term of the circumferential curvature

$k_{crit}$ values for the RP instability in figure 3 are found to be not affected by the slip. These values are determined by the competition between the two curvature terms for the Laplace pressure, shown on the right-hand side of (2.11), where the term of the circumferential curvature ![]() $1/ (h \sqrt {1+(\partial _x h )^2} )$ is the driving force, and the term of tangential curvature

$1/ (h \sqrt {1+(\partial _x h )^2} )$ is the driving force, and the term of tangential curvature ![]() $\partial _x^2 h/ (1+(\partial _x h )^2) ^{3/2}$ is the resisting force. The balance of the two forces gives

$\partial _x^2 h/ (1+(\partial _x h )^2) ^{3/2}$ is the resisting force. The balance of the two forces gives ![]() $k_{crit}$, which is independent of

$k_{crit}$, which is independent of ![]() $l_{s}$. The dominant wavenumber

$l_{s}$. The dominant wavenumber ![]() $k_{max}$ predicted by the Stokes model in figure 3 is shown to be modified by slip, while

$k_{max}$ predicted by the Stokes model in figure 3 is shown to be modified by slip, while ![]() $k_{max}$ from the lubrication model is unchanged with an analytical expression

$k_{max}$ from the lubrication model is unchanged with an analytical expression ![]() $k_{max} = \sqrt {1/2}$, derived from (3.18). The variations of

$k_{max} = \sqrt {1/2}$, derived from (3.18). The variations of ![]() $k_{max}$ with slip are illustrated further in figure 4(a), where

$k_{max}$ with slip are illustrated further in figure 4(a), where ![]() $k_{max}$ declines with increasing

$k_{max}$ declines with increasing ![]() $l_{s}$, possibly leading to larger drop sizes after the film breakup. This trend holds for different fibre radii with more rapid decrease of

$l_{s}$, possibly leading to larger drop sizes after the film breakup. This trend holds for different fibre radii with more rapid decrease of ![]() $k_{max}$ of thicker films (smaller

$k_{max}$ of thicker films (smaller ![]() $\alpha$). These findings indicate the limitations of the classical slip lubrication models (Liao et al. Reference Liao, Li and Wei2013; Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Halpern & Wei Reference Halpern and Wei2017; Chao et al. Reference Chao, Ding and Liu2018; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019), which can be severe with large slip, while the Stokes model proposed here has the capability of predicting the instability over a much larger range of

$\alpha$). These findings indicate the limitations of the classical slip lubrication models (Liao et al. Reference Liao, Li and Wei2013; Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Halpern & Wei Reference Halpern and Wei2017; Chao et al. Reference Chao, Ding and Liu2018; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019), which can be severe with large slip, while the Stokes model proposed here has the capability of predicting the instability over a much larger range of ![]() $l_{s}$. Additionally, the lubrication model shows that corresponding growth rates

$l_{s}$. Additionally, the lubrication model shows that corresponding growth rates ![]() $\omega _{max}$ of each

$\omega _{max}$ of each ![]() $k_{max}$ grow linearly with increasing

$k_{max}$ grow linearly with increasing ![]() $l_{s}$, which can be described by

$l_{s}$, which can be described by ![]() $\omega _{max} = -M/4$, while the Stokes model presents nonlinear growth with smaller

$\omega _{max} = -M/4$, while the Stokes model presents nonlinear growth with smaller ![]() $\omega _{max}$.

$\omega _{max}$.

Figure 4. Variations of the dominant wavenumber ![]() $k_{max}$ and corresponding growth rate

$k_{max}$ and corresponding growth rate ![]() $\omega _{max}$ with slip lengths. The solid and dashed lines are the predictions of the Stokes model (3.16) and the lubrication model (3.18), respectively, for different fibre thicknesses, i.e.

$\omega _{max}$ with slip lengths. The solid and dashed lines are the predictions of the Stokes model (3.16) and the lubrication model (3.18), respectively, for different fibre thicknesses, i.e. ![]() $\alpha =0.9$ (black),

$\alpha =0.9$ (black), ![]() $\alpha =0.7$ (blue),

$\alpha =0.7$ (blue), ![]() $\alpha =0.5$ (red) and

$\alpha =0.5$ (red) and ![]() $\alpha =0.3$ (purple).

$\alpha =0.3$ (purple).

4. Numerical simulations

In this section, direct numerical simulations are performed to support the theoretical findings in § 3 and provide more physical insights into the slip-enhanced RP instability of the cylindrical films on fibres. The open-source framework Basilisk (Popinet Reference Popinet2014, Reference Popinet2018) is employed to solve axisymmetric incompressible NS equations with surface tension. The interface between the high-density liquid and the low-density ambient air is reconstructed by a volume-of-fluid method, which has been validated by different kinds of interfacial flows such as jet breakup (Deblais et al. Reference Deblais, Herrada, Hauner, Velikov, Van Roon, Kellay, Eggers and Bonn2018), bubble bursting (Berny et al. Reference Berny, Deike, Séon and Popinet2020) and breaking waves (Mostert & Deike Reference Mostert and Deike2020).

The simulation domain is a rectangle (the section of a hollow cylinder in cylindrical coordinates) of size ![]() $[\alpha, 2]\times [0, L]$. Here,

$[\alpha, 2]\times [0, L]$. Here, ![]() $L$ is the length of the film/fibre, and

$L$ is the length of the film/fibre, and ![]() $\alpha$ is the radius of the fibre. The liquid film of initial radius

$\alpha$ is the radius of the fibre. The liquid film of initial radius ![]() $h_0 = 1$ is placed at the bottom of the domain, with small perturbations at the liquid–gas interface. The left and right boundary conditions of the simulation domain are considered periodic. The top is a symmetry boundary and bottom is a slip-wall boundary, as described by (2.13a,b). All simulations are performed in the dimensionless unit with the rescaling variables displayed in (2.1a–d). The non-dimensional parameter

$h_0 = 1$ is placed at the bottom of the domain, with small perturbations at the liquid–gas interface. The left and right boundary conditions of the simulation domain are considered periodic. The top is a symmetry boundary and bottom is a slip-wall boundary, as described by (2.13a,b). All simulations are performed in the dimensionless unit with the rescaling variables displayed in (2.1a–d). The non-dimensional parameter ![]() ${Oh}=10$ comes from liquid properties displayed in the previous experiment (Haefner Reference Haefner2015) with

${Oh}=10$ comes from liquid properties displayed in the previous experiment (Haefner Reference Haefner2015) with ![]() $h_0 = 10\ \mathrm {\mu }\mathrm {m}$,

$h_0 = 10\ \mathrm {\mu }\mathrm {m}$, ![]() $\rho =1.05\ \mathrm {g}\ \mathrm {cm}^{-3}$,

$\rho =1.05\ \mathrm {g}\ \mathrm {cm}^{-3}$, ![]() $\gamma = 30.8\ \mathrm {mN}\ \mathrm {m}^{{-1}}$ and

$\gamma = 30.8\ \mathrm {mN}\ \mathrm {m}^{{-1}}$ and ![]() $\mu =0.22\ \mathrm {kg}\ \mathrm {m}^{-1}\ \textrm {s}^{{-1}}$. Two configurations with different film lengths and initial perturbations are simulated here to investigate the influence of slip on the growth rates of perturbations (§ 4.1) and the dominant wavelength (§ 4.2), respectively.

$\mu =0.22\ \mathrm {kg}\ \mathrm {m}^{-1}\ \textrm {s}^{{-1}}$. Two configurations with different film lengths and initial perturbations are simulated here to investigate the influence of slip on the growth rates of perturbations (§ 4.1) and the dominant wavelength (§ 4.2), respectively.

4.1. Influence of slip on perturbation growth rates

To study the influence of slip on the growth rates, we consider simulations of a relatively short film ![]() $L=10$ with an initial perturbation

$L=10$ with an initial perturbation ![]() $h(x,t) =1+ \varepsilon \cos [2 {\rm \pi}(x/L-1/2)]$, where

$h(x,t) =1+ \varepsilon \cos [2 {\rm \pi}(x/L-1/2)]$, where ![]() $\varepsilon =0.01$. High-density grids are employed to capture the interface position and velocity profiles inside the film, with

$\varepsilon =0.01$. High-density grids are employed to capture the interface position and velocity profiles inside the film, with ![]() $2^{10}$ grid points along the

$2^{10}$ grid points along the ![]() $x$-axis. We choose three slip lengths, i.e.

$x$-axis. We choose three slip lengths, i.e. ![]() $l_{s}=0$,

$l_{s}=0$, ![]() $0.25$ and

$0.25$ and ![]() $0.5$, for two fibre radii,

$0.5$, for two fibre radii, ![]() $\alpha =0.7$ and

$\alpha =0.7$ and ![]() $0.5$.

$0.5$.

Figure 5 shows the simulation results on a no-slip fibre of the radius ![]() $\alpha =0.7$. The upper half of figure 5 shows a time evolution of the interface positions of the film, with the initial perturbations starting to grow due to the RP instability. The axial velocity

$\alpha =0.7$. The upper half of figure 5 shows a time evolution of the interface positions of the film, with the initial perturbations starting to grow due to the RP instability. The axial velocity ![]() $u(x,r)$ is crucial to understand influence of the slip on the fibre thinning, shown in the lower half of figure 5, where opposite fluxes are found to be directed towards the left and right boundaries, respectively, as the perturbation increases. More velocity fields are presented in figures 6(a,c,e) for three different slip lengths at

$u(x,r)$ is crucial to understand influence of the slip on the fibre thinning, shown in the lower half of figure 5, where opposite fluxes are found to be directed towards the left and right boundaries, respectively, as the perturbation increases. More velocity fields are presented in figures 6(a,c,e) for three different slip lengths at ![]() $t=100$. According to the variations of the contours in figures 6(a,c,e), the wall slip is found to accelerate the instability with larger

$t=100$. According to the variations of the contours in figures 6(a,c,e), the wall slip is found to accelerate the instability with larger ![]() $u(x,r)$. The velocity vectors in the lower plots of figures 6(a,c,e) show that slip decreases the velocity gradient

$u(x,r)$. The velocity vectors in the lower plots of figures 6(a,c,e) show that slip decreases the velocity gradient ![]() $\partial u/ \partial r$ near the fibre. The velocity profiles at different

$\partial u/ \partial r$ near the fibre. The velocity profiles at different ![]() $x$-coordinates (see the dashed lines with arrows in figures 6a,c,e) are also extracted from the contours, shown in figures 6(b,d, f), where the velocity on the fibre

$x$-coordinates (see the dashed lines with arrows in figures 6a,c,e) are also extracted from the contours, shown in figures 6(b,d, f), where the velocity on the fibre ![]() $u(x,\alpha )$ and its gradient

$u(x,\alpha )$ and its gradient ![]() $\partial _r u(x,\alpha )$ are calculated numerically. According to (2.13a,b),

$\partial _r u(x,\alpha )$ are calculated numerically. According to (2.13a,b), ![]() $l_{s} = u(x,\alpha ) / \partial _r u(x,\alpha )$. So we can have numerically predicted slip lengths at different positions, shown by the dashed lines in figures 6(d, f). These values agree with the input

$l_{s} = u(x,\alpha ) / \partial _r u(x,\alpha )$. So we can have numerically predicted slip lengths at different positions, shown by the dashed lines in figures 6(d, f). These values agree with the input ![]() $l_{s}$ in the boundary condition of the simulations, indicating that the numerical solutions can capture the flow features on the slip boundary conditions.

$l_{s}$ in the boundary condition of the simulations, indicating that the numerical solutions can capture the flow features on the slip boundary conditions.

Figure 5. Film thinning simulation results of one perturbation wave in an axially symmetric domain. For this case, ![]() $L=10$,

$L=10$, ![]() $l_{s}=0$ and

$l_{s}=0$ and ![]() $\alpha =0.7$. Interface profiles

$\alpha =0.7$. Interface profiles ![]() $h$ (upper half) and contours of the axial velocity

$h$ (upper half) and contours of the axial velocity ![]() $u(x,r,t)$ inside the film (lower half) are shown at three time instants: (a)

$u(x,r,t)$ inside the film (lower half) are shown at three time instants: (a) ![]() $t_1=300$, (b)

$t_1=300$, (b) ![]() $t_2=600$, (c)

$t_2=600$, (c) ![]() $t_3=900$. Here,

$t_3=900$. Here, ![]() $h_{min}$ represents the minimum radius of the film.

$h_{min}$ represents the minimum radius of the film.

Figure 6. Axial velocity fields at ![]() $t=100$ for different slip lengths: (a,b)

$t=100$ for different slip lengths: (a,b) ![]() $l_{s} = 0$, (c,d)

$l_{s} = 0$, (c,d) ![]() $l_{s} = 0.25$, (e, f)

$l_{s} = 0.25$, (e, f) ![]() $l_{s} = 0.5$. Here, the fibre radius is

$l_{s} = 0.5$. Here, the fibre radius is ![]() $\alpha = 0.7$. (a,c,e) Contours of the entire configuration (upper plots) and velocity vectors of the local field near

$\alpha = 0.7$. (a,c,e) Contours of the entire configuration (upper plots) and velocity vectors of the local field near ![]() $x=6$ (lower plots). (b,d, f) Velocity profiles at four local positions

$x=6$ (lower plots). (b,d, f) Velocity profiles at four local positions ![]() $x$:

$x$: ![]() $5.5$ (black), 6.0 (purple), 6.5 (blue) and 7.0 (red), shown by dashed lines with arrows in (a,c,e).

$5.5$ (black), 6.0 (purple), 6.5 (blue) and 7.0 (red), shown by dashed lines with arrows in (a,c,e).

Figure 7 illustrates the growth rates of perturbations in the six cases simulated here. Because ![]() $h(x,t) = 1+\hat {h}\,\textrm {e}^{\textrm {i}kx}\,\textrm {e}^{\omega t}$ is employed in the instability analysis (§ 3), we set the

$h(x,t) = 1+\hat {h}\,\textrm {e}^{\textrm {i}kx}\,\textrm {e}^{\omega t}$ is employed in the instability analysis (§ 3), we set the ![]() $y$-coordinate as

$y$-coordinate as ![]() $\ln (1-h_{min})$ to present the linear growth of perturbations. Here, the numerical solutions agree with predictions of the Stokes model, showing the capability of the Stokes model to describe the RP instability of films on slippery fibres, while the predictions of the lubrication model are not accurate for the slip cases. These results are consistent with dispersion relations in figure 3 and confirm the Stokes model numerically.

$\ln (1-h_{min})$ to present the linear growth of perturbations. Here, the numerical solutions agree with predictions of the Stokes model, showing the capability of the Stokes model to describe the RP instability of films on slippery fibres, while the predictions of the lubrication model are not accurate for the slip cases. These results are consistent with dispersion relations in figure 3 and confirm the Stokes model numerically.

Figure 7. Linear time evolution of the minimum radii of films ![]() $h_{min}(t)$ on two fibre radii: (a)

$h_{min}(t)$ on two fibre radii: (a) ![]() $\alpha =0.7$, (b)

$\alpha =0.7$, (b) ![]() $\alpha =0.5$. The numerical solutions (dotted lines with symbols) are compared to the predictions of both the lubrication model (dashed lines) and Stokes model (solid lines) for three slip lengths:

$\alpha =0.5$. The numerical solutions (dotted lines with symbols) are compared to the predictions of both the lubrication model (dashed lines) and Stokes model (solid lines) for three slip lengths: ![]() $l_{s} = 0$ (black),

$l_{s} = 0$ (black), ![]() $l_{s}=0.25$ (red) and

$l_{s}=0.25$ (red) and ![]() $l_{s}=0.5$ (blue). The inset illustrates

$l_{s}=0.5$ (blue). The inset illustrates ![]() $h_{min}(t)$ in the uniform grids. Here,

$h_{min}(t)$ in the uniform grids. Here, ![]() $t$ is scaled by

$t$ is scaled by ![]() $\mu h_0/\gamma$.

$\mu h_0/\gamma$.

Based on the approach proposed by Liao et al. (Reference Liao, Li and Wei2013) and Wei, Tsao & Chu (Reference Wei, Tsao and Chu2019), we have a physical explanation for why large slip causes the failure of lubrication models, i.e. the radial derivative of the axial velocity is no longer much larger than its axial derivative, violating the lubrication approximation ![]() $| {\partial ^2 u}/{\partial x^2} | / |({1}/{r}) ({\partial }/{\partial r})(r ({\partial u}/{\partial r}) )| \ll 1$ (see more details in Appendix A). Figure 8 shows the contour inside the film of the ratio

$| {\partial ^2 u}/{\partial x^2} | / |({1}/{r}) ({\partial }/{\partial r})(r ({\partial u}/{\partial r}) )| \ll 1$ (see more details in Appendix A). Figure 8 shows the contour inside the film of the ratio ![]() $| {\partial ^2 u}/{\partial x^2} | / |({1}/{r})({\partial }/{\partial r})(r ({\partial u}/{\partial r}) )|$, extracted from the numerical solutions in this section. The ratio is found to increase from about

$| {\partial ^2 u}/{\partial x^2} | / |({1}/{r})({\partial }/{\partial r})(r ({\partial u}/{\partial r}) )|$, extracted from the numerical solutions in this section. The ratio is found to increase from about ![]() $0.01$ for the no-slip case to

$0.01$ for the no-slip case to ![]() $0.1$ for the slip case (

$0.1$ for the slip case (![]() $l_{s}=0.5$) at the same location, which is consistent with the physical explanation above.

$l_{s}=0.5$) at the same location, which is consistent with the physical explanation above.

Figure 8. Ratio of the velocity gradients at ![]() $t=100$ for different slip lengths: (a)

$t=100$ for different slip lengths: (a) ![]() $l_{s} = 0$, (b)

$l_{s} = 0$, (b) ![]() $l_{s} = 0.25$, (c)

$l_{s} = 0.25$, (c) ![]() $l_{s} = 0.5$. Here, the fibre radius is

$l_{s} = 0.5$. Here, the fibre radius is ![]() $\alpha = 0.7$, and

$\alpha = 0.7$, and ![]() $u_{xx}$ and

$u_{xx}$ and ![]() $(r u_r)_r/r$ represents the second-order axial and radial derivatives of the axial velocity in (A24), respectively.

$(r u_r)_r/r$ represents the second-order axial and radial derivatives of the axial velocity in (A24), respectively.

4.2. Influence of slip on the dominant wavelength

For the influence of slip on the dominant wavelengths, we consider a configuration of a long film ![]() $L=160$ with

$L=160$ with ![]() $2^{13}$ grid points along the

$2^{13}$ grid points along the ![]() $x$-axis. Eight different cases are simulated with four slip lengths, i.e.

$x$-axis. Eight different cases are simulated with four slip lengths, i.e. ![]() $l_{s}=0$,

$l_{s}=0$, ![]() $1$,

$1$, ![]() $2$ and

$2$ and ![]() $3$ on fibres of two radii,

$3$ on fibres of two radii, ![]() $\alpha =0.7$ and

$\alpha =0.7$ and ![]() $0.5$.

$0.5$.

The simulations start from random initial perturbations ![]() $h(x,0) = 1+ \varepsilon \,N(x)$, where

$h(x,0) = 1+ \varepsilon \,N(x)$, where ![]() $\varepsilon = 2 \times 10^{-3}$, and the random number

$\varepsilon = 2 \times 10^{-3}$, and the random number ![]() $N(x)$ follows a normal distribution with zero mean and unit variance. The random initial perturbations are designed to mimic numerically the arbitrary disturbances in the experiment (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). Figure 9 presents the spatial and temporal evolutions of interface profiles

$N(x)$ follows a normal distribution with zero mean and unit variance. The random initial perturbations are designed to mimic numerically the arbitrary disturbances in the experiment (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). Figure 9 presents the spatial and temporal evolutions of interface profiles ![]() $h(x,t)$, where these small random perturbations, driven by the surface tension in the RP instability, grow gradually against time to generate significant capillary waves at early stages, plotted in figure 9(b). Figure 9(c) shows that wavelengths of these capillary waves are unchanged at the later stage of perturbation growth.

$h(x,t)$, where these small random perturbations, driven by the surface tension in the RP instability, grow gradually against time to generate significant capillary waves at early stages, plotted in figure 9(b). Figure 9(c) shows that wavelengths of these capillary waves are unchanged at the later stage of perturbation growth.

Figure 9. (a) Space–time plot of interface positions ![]() $h(x,t)$ on a no-slip fibre of the radius

$h(x,t)$ on a no-slip fibre of the radius ![]() $\alpha =0.7$. Darker (brighter) colours correspond to the smaller (larger) values of

$\alpha =0.7$. Darker (brighter) colours correspond to the smaller (larger) values of ![]() $h(x,t)$. (b,c) Interface profiles extracted from (a) at early and late stages of the instability.

$h(x,t)$. (b,c) Interface profiles extracted from (a) at early and late stages of the instability.

To further prove the previous findings and confirm theoretical predictions of the Stokes model quantitatively, multiple independent simulations (five for each case) are performed to gather statistics of the dominant modes with a statistical methodology proposed by Zhao, Sprittles & Lockerby (Reference Zhao, Sprittles and Lockerby2019). For each realisation, a discrete Fourier transform of the interface position ![]() $h(x)$ is applied to get the power spectral density (PSD) of the perturbations. The square root of the ensemble-averaged PSD (

$h(x)$ is applied to get the power spectral density (PSD) of the perturbations. The square root of the ensemble-averaged PSD (![]() $H_{rms}$) at each time is plotted in figures 10(a,b) with a modal distribution (spectrum) fitted by the Gaussian function, where the peak represents the dominant wavenumber

$H_{rms}$) at each time is plotted in figures 10(a,b) with a modal distribution (spectrum) fitted by the Gaussian function, where the peak represents the dominant wavenumber ![]() $k_{max}$ (see black dash-dotted lines). Extracting

$k_{max}$ (see black dash-dotted lines). Extracting ![]() $k_{max}$ from the fitted spectrum at each time instant yields the insets in figures 10(a,b). Promisingly,

$k_{max}$ from the fitted spectrum at each time instant yields the insets in figures 10(a,b). Promisingly, ![]() $k_{max}$ converges rapidly to a constant in both cases, further supporting the findings in figure 9(c). Here, we compare these constants with the

$k_{max}$ converges rapidly to a constant in both cases, further supporting the findings in figure 9(c). Here, we compare these constants with the ![]() $k_{max}$ predicted by the Stokes model. Similar statistical analysis is applied for other cases to generate the symbols (

$k_{max}$ predicted by the Stokes model. Similar statistical analysis is applied for other cases to generate the symbols (![]() $\lambda _{max} = 2 {\rm \pi}/k_{max}$) in figure 10(c), giving good agreement with theoretical predictions. Therefore, we can conclude that the dominant modes depend strongly on slip lengths with longer perturbation waves formed on a more slippery surface.

$\lambda _{max} = 2 {\rm \pi}/k_{max}$) in figure 10(c), giving good agreement with theoretical predictions. Therefore, we can conclude that the dominant modes depend strongly on slip lengths with longer perturbation waves formed on a more slippery surface.

Figure 10. (a,b) The root mean square (r.m.s.) of non-dimensional perturbation amplitude versus non-dimensional wavenumber on fibres with different slip lengths, at four time instants: (a) ![]() $2\times 10^3$ (green),

$2\times 10^3$ (green), ![]() $4.5\times 10^3$ (black),

$4.5\times 10^3$ (black), ![]() $6\times 10^3$ (red) and

$6\times 10^3$ (red) and ![]() $7\times 10^3$ (blue); (b)

$7\times 10^3$ (blue); (b) ![]() $1.2\times 10^2$ (green),

$1.2\times 10^2$ (green), ![]() $3.3\times 10^2$ (black),

$3.3\times 10^2$ (black), ![]() $4.2\times 10^2$ (red) and

$4.2\times 10^2$ (red) and ![]() $4.8\times 10^2$ (blue). The inset shows the time history of the dominant wavenumber. (c) Variations of the dominant wavelengths with slip lengths: a comparison between the theoretical predictions of (3.16) and numerical solutions for two fibres of different radii.

$4.8\times 10^2$ (blue). The inset shows the time history of the dominant wavenumber. (c) Variations of the dominant wavelengths with slip lengths: a comparison between the theoretical predictions of (3.16) and numerical solutions for two fibres of different radii.

Figure 11 shows the influence of slip on the droplet size. In figure 11(a), larger drops are formed on slippery fibres with obviously longer wavelengths compared to ones achieved on the no-slip boundary, consistent with the theoretical results in figure 10(c) qualitatively. Furthermore, we define the area between two bottom points of ![]() $h(x)$ as one droplet. Performing statistical analysis for all realisations gives the droplet-size distribution of slip and no-slip cases, illustrated in figure 11(b), whose mean and standard deviation are achieved by fitting the Gaussian function (red dash-dotted lines). The slip case has a larger mean value of the distribution, further proving the finding in figure 11(a). Besides the mean, slip is also found to lead to a wider distribution, with a larger standard deviation, possibly because the slip wall imposes fewer restrictions (shear stresses on the fibre, i.e.

$h(x)$ as one droplet. Performing statistical analysis for all realisations gives the droplet-size distribution of slip and no-slip cases, illustrated in figure 11(b), whose mean and standard deviation are achieved by fitting the Gaussian function (red dash-dotted lines). The slip case has a larger mean value of the distribution, further proving the finding in figure 11(a). Besides the mean, slip is also found to lead to a wider distribution, with a larger standard deviation, possibly because the slip wall imposes fewer restrictions (shear stresses on the fibre, i.e. ![]() $\tilde {\tau }_{w} = \mu \,\partial _{\tilde {r}} \tilde {u}(\tilde {x},a)$) on the liquid compared to the no-slip wall. The perturbation wavelengths have more ‘freedom’ to expand or shrink, leading to a wider wavelength distribution. Note that figure 11 might not be the final equilibrium state. So droplet coalescence could happen with complicated nonlinear dynamics. However, these nonlinear behaviours are beyond the scope of this work and should be the subject of future investigation.

$\tilde {\tau }_{w} = \mu \,\partial _{\tilde {r}} \tilde {u}(\tilde {x},a)$) on the liquid compared to the no-slip wall. The perturbation wavelengths have more ‘freedom’ to expand or shrink, leading to a wider wavelength distribution. Note that figure 11 might not be the final equilibrium state. So droplet coalescence could happen with complicated nonlinear dynamics. However, these nonlinear behaviours are beyond the scope of this work and should be the subject of future investigation.

Figure 11. (a) Interface profiles of liquid films on fibres of radius ![]() $\alpha =0.7$. The results for two slip lengths are presented by a solid blue line for

$\alpha =0.7$. The results for two slip lengths are presented by a solid blue line for ![]() $l_{s}=0$, and a red dash-dotted line for

$l_{s}=0$, and a red dash-dotted line for ![]() $l_{s}=3$. (b) Distributions of the droplet size on the no-slip (upper plot) and slip (lower plot).

$l_{s}=3$. (b) Distributions of the droplet size on the no-slip (upper plot) and slip (lower plot).

5. Comparisons with experimental results

Besides the numerical validations, the Stokes model is compared further with the experimental results in the previous work done by Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). The experiments were done by measuring the evolutions of entangled polystyrene films with homogeneous initial thicknesses on no-slip and slip fibres of radius ![]() $a=9.6\ \mathrm {\mu }\textrm {m}$.

$a=9.6\ \mathrm {\mu }\textrm {m}$.

Figure 12 displays the dimensional dominant wavelengths ![]() $\tilde {\lambda }_{max}$ (

$\tilde {\lambda }_{max}$ (![]() $\lambda _{max} h_0$) of liquid films with different initial thicknesses

$\lambda _{max} h_0$) of liquid films with different initial thicknesses ![]() $h_0$, where the blue triangles and red dots represent experimental data of the films on no-slip and slip fibres, respectively. Since

$h_0$, where the blue triangles and red dots represent experimental data of the films on no-slip and slip fibres, respectively. Since ![]() $\lambda _{max}$ predicted by the lubrication model (3.18) is the constant (

$\lambda _{max}$ predicted by the lubrication model (3.18) is the constant (![]() $\lambda _{max}=2\sqrt {2}{\rm \pi}$), independent of both

$\lambda _{max}=2\sqrt {2}{\rm \pi}$), independent of both ![]() $l_{s}$ and

$l_{s}$ and ![]() $\alpha$,

$\alpha$, ![]() $\lambda _{max} h_0$ grows linearly with increasing

$\lambda _{max} h_0$ grows linearly with increasing ![]() $h_0$ (see the black dashed line in figure 12). However, the lubrication model seemingly underestimates experimentally obtained

$h_0$ (see the black dashed line in figure 12). However, the lubrication model seemingly underestimates experimentally obtained ![]() $\lambda _{max}$. The possible reason is that most

$\lambda _{max}$. The possible reason is that most ![]() $\alpha$ values investigated in the experiment are smaller than

$\alpha$ values investigated in the experiment are smaller than ![]() $0.5$, outside the range of validity of the lubrication approximation. A series of dominant wavelengths with different

$0.5$, outside the range of validity of the lubrication approximation. A series of dominant wavelengths with different ![]() $\alpha$ values are extracted from the Stokes model (3.16) to generate a blue solid line for no-slip cases, and a red dash-dotted line for slip cases with a fitting

$\alpha$ values are extracted from the Stokes model (3.16) to generate a blue solid line for no-slip cases, and a red dash-dotted line for slip cases with a fitting ![]() $\tilde {l}_{s}$ in figure 12. Note that the dimensionless slip length varies along the red dash-dotted curve with different

$\tilde {l}_{s}$ in figure 12. Note that the dimensionless slip length varies along the red dash-dotted curve with different ![]() $h_0$ values. Though both the blue and red curves still look linear due to small changes of

$h_0$ values. Though both the blue and red curves still look linear due to small changes of ![]() $\lambda _{max}$, obvious differences between the Stokes predictions and the lubrication ones are found for the thick films (

$\lambda _{max}$, obvious differences between the Stokes predictions and the lubrication ones are found for the thick films (![]() $h_0>40\ \mathrm {\mu }\textrm {m}$). Promisingly, despite dispersion of experimental data, the Stokes model can provide better predictions for dominant wavelengths of both no-slip cases and slip cases compared to the lubrication model.

$h_0>40\ \mathrm {\mu }\textrm {m}$). Promisingly, despite dispersion of experimental data, the Stokes model can provide better predictions for dominant wavelengths of both no-slip cases and slip cases compared to the lubrication model.

Figure 12. Influence of the geometry on the dominant wavelength of the instability: a comparison between the theoretical predictions and experimental data. The experimental data come from the work of Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015).

In addition to the dominant wavelengths, we then make a further comparison between the experimental growth rates and theoretical ones, illustrated in figure 13, where the growth rate is non-dimensionalised by the ratio of the capillary velocity to the fibre radius, i.e. ![]() $\omega =({a}\tilde {\omega }/({\gamma /\mu }))$. However, using the parameters from Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015) (

$\omega =({a}\tilde {\omega }/({\gamma /\mu }))$. However, using the parameters from Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015) (![]() $\gamma /\mu = 294\ \mathrm {\mu }\mathrm {m}\ \min ^{-1}$ and

$\gamma /\mu = 294\ \mathrm {\mu }\mathrm {m}\ \min ^{-1}$ and ![]() $\tilde {l}_{s} = 0.3\,a$), the Stokes model is found to provide worse agreements with the experimental data than the lubrication model. Noticeably, predictions of the lubrication model match the experimental data even in the case of thick films (

$\tilde {l}_{s} = 0.3\,a$), the Stokes model is found to provide worse agreements with the experimental data than the lubrication model. Noticeably, predictions of the lubrication model match the experimental data even in the case of thick films (![]() $h_0/a > 3$), which is unreasonable due to the thin-film assumption in the lubrication theory. The reason for the disagreement is currently unclear and should be the subject of future investigation.

$h_0/a > 3$), which is unreasonable due to the thin-film assumption in the lubrication theory. The reason for the disagreement is currently unclear and should be the subject of future investigation.

Figure 13. Influence of the geometry on the growth rate of the dominant mode on no-slip and slip fibres. The solid lines and dashed lines are the predictions of the Stokes model and the lubrication model, respectively. Blue lines represent no-slip results, and red lines are the slip ones. The experimental data come from the work of Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015).

6. Conclusions

In this work, to study the influence of liquid–solid slip on the RP instability of liquid films on a fibre, a theoretical model based on the linear stability analysis of axisymmetric Stokes equations is developed, which goes beyond the classical slip lubrication model. The lubrication model is found to overestimate the slip-enhanced growth rates of perturbations and fails to predict the dominant wavelength, while the new model can provide more accurate predictions for the instability. Direct numerical simulations of the NS equations are then performed to validate the two theoretical findings via two fluid configurations: (i) a short film with a fixed wavelength for the slip-enhanced growth rate of the perturbation; and (ii) a long film with random initial perturbations for the slip-dependent dominant modes of perturbations. The dominant wavelengths are also confirmed by experimental data from previous work (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). Overall, the applicability of the slip lubrication model should be restricted to thin-film and small-slip flows. For more general problems, it is better to use the Stokes theory proposed here.

Promisingly, the wall slip has been realised experimentally for films on a fibre (Haefner et al. Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015; Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019), and the slip length can also be measured directly (Huang, Guasto & Breuer Reference Huang, Guasto and Breuer2006; Maali & Bhushan Reference Maali and Bhushan2012; Maali, Colin & Bhushan Reference Maali, Colin and Bhushan2016). It is our hope that the wall slip can be controlled experimentally to verify our new predictions, most notably the relation between drop sizes (![]() $\lambda _{max}$) and slip lengths. Potential extensions of the framework are numerous: for example, to include the influence of other physics, such as electric fields (Ding et al. Reference Ding, Xie, Wong and Liu2014) and intermolecular forces (Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019; Tomo et al. Reference Tomo, Nag and Takamatsu2022), both of which are known to affect

$\lambda _{max}$) and slip lengths. Potential extensions of the framework are numerous: for example, to include the influence of other physics, such as electric fields (Ding et al. Reference Ding, Xie, Wong and Liu2014) and intermolecular forces (Ji et al. Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019; Tomo et al. Reference Tomo, Nag and Takamatsu2022), both of which are known to affect ![]() $k_{crit}$ and

$k_{crit}$ and ![]() $k_{max}$ in the RP instability, and to explore related flow configurations, like a film flowing down a fibre (Liu & Ding Reference Liu and Ding2021), where an interesting open problem is to understand the influence of slip on dynamics of travelling waves in different flow regimes.

$k_{max}$ in the RP instability, and to explore related flow configurations, like a film flowing down a fibre (Liu & Ding Reference Liu and Ding2021), where an interesting open problem is to understand the influence of slip on dynamics of travelling waves in different flow regimes.

Acknowledgements

Useful discussions with Dr M. Chubynsky, Dr M. Kai, Mr Q. Ran and Dr Q. Jian are gratefully acknowledged.

Funding

This work was supported by the National Natural Science Foundation of China (grant no. 11621202) and the Youth Innovation Promotion Association CAS (grant no. 2018491).

Declaration of interests

The authors report no conflict of interest.

Appendix A. Derivation for the lubrication equation

In this Appendix, we present a detailed reproduction of the derivation of the lubrication equation used by Haefner et al. (Reference Haefner, Benzaquen, Bäumchen, Salez, Peters, McGraw, Jacobs, Raphaël and Dalnoki-Veress2015). To get this lubrication equation from the axisymmetric NS equations, we need to establish the leading-order terms by their asymptotic expansion in ![]() $\varepsilon$, for which we use the rescaling

$\varepsilon$, for which we use the rescaling

Here, ![]() $\tilde {\lambda } = h_0 / \varepsilon$. Substituting all these scalings into the dimensional Stokes equations yields

$\tilde {\lambda } = h_0 / \varepsilon$. Substituting all these scalings into the dimensional Stokes equations yields

The equations at the liquid–gas interface (![]() $r=h$) are scaled as

$r=h$) are scaled as

\begin{gather} p - \frac{2 \varepsilon^2}{1+ \varepsilon^2 \left(\partial_x h \right)^2} \left[ \frac{\partial v}{\partial r} - \frac{\partial h}{\partial x} \left( \frac{\partial u}{\partial r} + \varepsilon^2\,\frac{\partial v}{\partial x}\right) + \varepsilon^2 \left(\frac{\partial h}{\partial x} \right)^2 \frac{\partial u}{\partial x} \right] \nonumber\\ \hspace{-4.5pc} =\frac{1}{\varepsilon^2 h \sqrt{1+ \varepsilon^2 \left(\partial_x h \right)^2}} - \frac{\partial_x^2 h}{\left(1+\varepsilon^2 \left(\partial_x h \right)^2\right) ^{3/2}} , \end{gather}

\begin{gather} p - \frac{2 \varepsilon^2}{1+ \varepsilon^2 \left(\partial_x h \right)^2} \left[ \frac{\partial v}{\partial r} - \frac{\partial h}{\partial x} \left( \frac{\partial u}{\partial r} + \varepsilon^2\,\frac{\partial v}{\partial x}\right) + \varepsilon^2 \left(\frac{\partial h}{\partial x} \right)^2 \frac{\partial u}{\partial x} \right] \nonumber\\ \hspace{-4.5pc} =\frac{1}{\varepsilon^2 h \sqrt{1+ \varepsilon^2 \left(\partial_x h \right)^2}} - \frac{\partial_x^2 h}{\left(1+\varepsilon^2 \left(\partial_x h \right)^2\right) ^{3/2}} , \end{gather} \begin{gather} 2 \varepsilon^2\,\frac{\partial h}{\partial x} \left( \frac{\partial v}{\partial r} - \frac{\partial u}{\partial x} \right) + \left[ 1- \varepsilon^2 \left(\frac{\partial h}{\partial x} \right)^2 \right] \left( \frac{\partial u}{\partial r} + \varepsilon^2\,\frac{\partial v}{\partial x} \right) = 0 . \end{gather}

\begin{gather} 2 \varepsilon^2\,\frac{\partial h}{\partial x} \left( \frac{\partial v}{\partial r} - \frac{\partial u}{\partial x} \right) + \left[ 1- \varepsilon^2 \left(\frac{\partial h}{\partial x} \right)^2 \right] \left( \frac{\partial u}{\partial r} + \varepsilon^2\,\frac{\partial v}{\partial x} \right) = 0 . \end{gather}

For the boundary conditions at the liquid–solid interface (![]() $r=\alpha$), the scaled forms are

$r=\alpha$), the scaled forms are

After eliminating all the high-order terms of ![]() $\varepsilon$, we obtain

$\varepsilon$, we obtain

Notably, the term ![]() $\partial _x^2 h$ is not in the leading order compared to

$\partial _x^2 h$ is not in the leading order compared to ![]() $1/h$ in (A13), but conventionally in this field, it is still included in the pressure in an attempt to extend the validity of the model (Eggers & Dupont Reference Eggers and Dupont1994; Craster & Matar Reference Craster and Matar2006). Additionally, (A8a,b) shows that the leading-order slip boundary depends on the ratio

$1/h$ in (A13), but conventionally in this field, it is still included in the pressure in an attempt to extend the validity of the model (Eggers & Dupont Reference Eggers and Dupont1994; Craster & Matar Reference Craster and Matar2006). Additionally, (A8a,b) shows that the leading-order slip boundary depends on the ratio ![]() $\tilde {l}_{s}/h_0$. In this work, we consider that the slip is of the order of

$\tilde {l}_{s}/h_0$. In this work, we consider that the slip is of the order of ![]() $h_0$, so the scaled slip boundary condition is unchanged in (A15).

$h_0$, so the scaled slip boundary condition is unchanged in (A15).

Integrating (A10) from ![]() $r=h$ to

$r=h$ to ![]() $r=r$ with the boundary condition equation (A14) gives

$r=r$ with the boundary condition equation (A14) gives

After integrating (A17) from ![]() $r=\alpha$ to

$r=\alpha$ to ![]() $r=r$ with the slip boundary condition (A15), we have

$r=r$ with the slip boundary condition (A15), we have

Combining (A17) and (A18) yields

Using (A9), (A12) and (A16) with the Leibniz integral rule, one can obtain

Substituting (A19) into the integral results in

where

and