Impact Statement

The characterization of the effects of panel flexibility on the dynamics of separated shock–turbulent boundary layer interactions is important in high-speed flight and propulsion applications, as vibrational modes of increasingly lighter structures can couple with the low-frequency flow motions of the shock system and separation bubble. The proposed use of wall-modelled large-eddy simulation (WMLES) in a loosely coupled partitioned fluid–structure interaction simulation method results in significant savings in computational cost while maintaining physical fidelity of critical flow features such as separation and reattachment, which cannot be properly captured by lower-fidelity flow simulation methods. The reduced cost of WMLES, compared with wall-resolved LES, allows sufficiently long integration times needed to capture the low-frequency motions of interest of the flow and structure. Considering structural damping in the solid mechanics solver results in better accuracy than prior simulation efforts. By complementing experimental measurements, our numerical results indicate that the separation bubble characteristics (size and dynamics) are significantly affected by panel deformation, and can be rather sensitive to small variations in the incoming boundary layer and shock-generating method.

1. Introduction

Interactions between shock waves and turbulent boundary layers (STBLIs) are critical to the design of supersonic and hypersonic flying vehicles. Researched for decades (Reference DollingDolling, 2001), most STBLI studies have focused on interactions with boundary layers developed over rigid walls (Reference Délery and DussaugeDélery & Dussauge, 2009). The fluid–structural coupling of STBLIs has not been studied nearly as extensively despite its relevance in internal (e.g. scramjet engines) and external (e.g. aerodynamic control surfaces) flows over lightweight, thin panels (Reference McNamara and FriedmannMcNamara & Friedmann, 2011). Of particular concern is the potential coupling of vibrational modes of the panel (e.g. engine walls, control surfaces) with the characteristic low-frequency motions of the shock system and separated flow region that arise for sufficiently strong interactions (Reference Clemens and NarayanaswamyClemens & Narayanaswamy, 2014), which can lead to flow-induced cyclic loading, structural fatigue and failure. Wall deformation can, in turn, alter the flow characteristics of the STBLI, including the shock system, turbulence amplification, boundary layer development and separation.

Turbulent flows over elastic panels without the influence of incident shock have also been the subject of recent investigations. Reference Ostoich, Bodony and GeubelleOstoich, Bodony, and Geubelle (2013) numerically studied the interaction between a thin steel panel and a compressible turbulent boundary layer with ![]() $M_\infty = 2.25$ (similar to the experiments conducted by Reference Beberniss, Spottswood and EasonBeberniss, Spottswood, and Eason (2011)), finding that the compliant panel modified the turbulence statistics under limit-cycle oscillation. These modified turbulence statistics were found to converge back to the original rigid panel form within one integral length of the turbulent boundary layer downstream of the panel. Reference Sullivan and BodonySullivan and Bodony (2019) performed high-fidelity two-dimensional laminar unsteady simulations in conjunction with the experiments of Reference Whalen, Kennedy, Laurence, Sullivan, Bodony and BuckWhalen et al. (2019) of a

$M_\infty = 2.25$ (similar to the experiments conducted by Reference Beberniss, Spottswood and EasonBeberniss, Spottswood, and Eason (2011)), finding that the compliant panel modified the turbulence statistics under limit-cycle oscillation. These modified turbulence statistics were found to converge back to the original rigid panel form within one integral length of the turbulent boundary layer downstream of the panel. Reference Sullivan and BodonySullivan and Bodony (2019) performed high-fidelity two-dimensional laminar unsteady simulations in conjunction with the experiments of Reference Whalen, Kennedy, Laurence, Sullivan, Bodony and BuckWhalen et al. (2019) of a ![]() $M_\infty = 6.04$ flow over a

$M_\infty = 6.04$ flow over a ![]() $35^{\circ }$ compression ramp with an embedded compliant panel. Several reduced-order models based on piston theory were assessed. Models using localized piston theory were found to have good agreement with the conducted high-fidelity simulations. Reference Whalen, Schöneich, Laurence, Sullivan, Bodony, Freydin and BuckWhalen et al. (2020) experimentally investigated the effect of aerothermal heating on the same flow with a compliant panel and observed enhanced static deformations and frequency shifting. Comparison with an equivalent rigid panel configuration showed evidence of panel vibration in the downstream portion of the flow field.

$35^{\circ }$ compression ramp with an embedded compliant panel. Several reduced-order models based on piston theory were assessed. Models using localized piston theory were found to have good agreement with the conducted high-fidelity simulations. Reference Whalen, Schöneich, Laurence, Sullivan, Bodony, Freydin and BuckWhalen et al. (2020) experimentally investigated the effect of aerothermal heating on the same flow with a compliant panel and observed enhanced static deformations and frequency shifting. Comparison with an equivalent rigid panel configuration showed evidence of panel vibration in the downstream portion of the flow field.

Recently, an increasing number of experiments have investigated the coupling of STBLIs with flexible panels. Reference Spottswood, Eason and BebernissSpottswood, Eason, and Beberniss (2012) performed oblique shock impingement experiments on a compliant panel that was fixed on all four sides. In a sequence of experiments targeting statistically quasi-two-dimensional configurations of oblique STBLIs impinging on a rectangular thin flexible panel, Reference Willems, Gulhan and EsserWillems, Gulhan, and Esser (2013) and Reference Daub, Willems and GülhanDaub, Willems, and Gülhan (2016) investigated the effects of the free-stream Mach number (![]() $M_{\infty }$) and the incident oblique shock angle (

$M_{\infty }$) and the incident oblique shock angle (![]() $\theta$). By carefully controlling the pressure differential across the flexible panel, Reference Varigonda and NarayanaswamyVarigonda and Narayanaswamy (2019) investigated interactions resulting in concave and convex panel curvature. Reference Tripathi, Mears, Shoele and KumarTripathi, Mears, Shoele, and Kumar (2020) assessed the effects of the Reynolds number, shock impingement location and cavity pressure on the panel dynamics and separation bubble characteristics in

$\theta$). By carefully controlling the pressure differential across the flexible panel, Reference Varigonda and NarayanaswamyVarigonda and Narayanaswamy (2019) investigated interactions resulting in concave and convex panel curvature. Reference Tripathi, Mears, Shoele and KumarTripathi, Mears, Shoele, and Kumar (2020) assessed the effects of the Reynolds number, shock impingement location and cavity pressure on the panel dynamics and separation bubble characteristics in ![]() $M_{\infty } = 2$ oblique STBLIs. Testing

$M_{\infty } = 2$ oblique STBLIs. Testing ![]() $M_{\infty } = 2$ oblique and

$M_{\infty } = 2$ oblique and ![]() $M_{\infty } = 1.4$ normal STBLI–panel coupling, Reference Gramola, Bruce and SanterGramola, Bruce, and Santer (2020) found a strong influence of the cavity pressure on the aerostructural dynamics, suggesting potential strategies of wave drag passive control through adaptive shock control bumps. Experiments of

$M_{\infty } = 1.4$ normal STBLI–panel coupling, Reference Gramola, Bruce and SanterGramola, Bruce, and Santer (2020) found a strong influence of the cavity pressure on the aerostructural dynamics, suggesting potential strategies of wave drag passive control through adaptive shock control bumps. Experiments of ![]() $M_{\infty } = 4$ STBLIs impinging on a thin steel panel by Reference Neet and AustinNeet and Austin (2020) observed a flattened and elongated separation region and a reduction of static pressure in the flexible configuration, relative to a rigid panel.

$M_{\infty } = 4$ STBLIs impinging on a thin steel panel by Reference Neet and AustinNeet and Austin (2020) observed a flattened and elongated separation region and a reduction of static pressure in the flexible configuration, relative to a rigid panel.

Several measurement challenges remain that prevent a complete characterization of these coupled interactions, especially of the near-wall flow physics, from experiments alone (Reference Riley, Perez, Bartram, Spottswood, Smarslok and BebernissRiley et al., 2019). Numerical simulations thus play a crucial role to complement experiments and provide missing fundamental insight. To predict aerodynamic forces acting on a deforming structure, simplified formulations based on piston, Van Dyke and shock-expansion theories are common for quasi-steady interactions, due to the minimal computational cost (Reference Brouwer and McNamaraBrouwer & McNamara, 2019; Reference McNamara and FriedmannMcNamara & Friedmann, 2007; Reference Sullivan and BodonySullivan & Bodony, 2019; Reference Sullivan, Bodony, Whalen and LaurenceSullivan, Bodony, Whalen, & Laurence, 2020). For higher physical fidelity, prior studies have resorted to solving the inviscid Euler flow equations (Reference VisbalVisbal, 2012) or the Navier–Stokes equations via Reynolds-averaged Navier–Stokes (RANS) approaches (Reference Gogulapati, Deshmukh, Crowell, McNamara, Vyas, Wang and EasonGogulapati et al., 2014; Reference Shahriar, Shoele and KumarShahriar, Shoele, & Kumar, 2018; Reference VisbalVisbal, 2014; Reference Yao, Zhang and LiuYao, Zhang, & Liu, 2017), detached-eddy simulations (Reference Gan and ZhaGan & Zha, 2016), large-eddy simulation (LES) (Reference Borazjani and AkbarzadehBorazjani & Akbarzadeh, 2020; Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al., 2015) or direct numerical simulation (Reference Shinde, McNamara, Gaitonde, Barnes and VisbalShinde, McNamara, Gaitonde, Barnes & Visbal, 2018), coupled with structural solvers (Reference Schemmel, Collins, Bhushan and BhatiaSchemmel, Collins, Bhushan, & Bhatia, 2020). Although attractive from a computational cost standpoint, RANS approaches cannot accurately predict strong flow separation and associated low-frequency dynamics in STBLIs (Reference Sadagopan, Huang, Xu and YangSadagopan, Huang, Xu, & Yang, 2021). The stringent grid resolution requirements of direct numerical simulation and wall-resolved LES render these simulation methods still prohibitively expensive beyond moderate Reynolds numbers, particularly for the long integration times required to capture low-frequency motions and under interactions with spanwise inhomogeneity (brought, for example, by the panel deflection).

Wall-modelled LES (WMLES) (Reference Bose and ParkBose & Park, 2018; Reference Larsson, Kawai, Bodart and Bermejo-MorenoLarsson, Kawai, Bodart, & Bermejo-Moreno, 2016) greatly reduces the computational cost of simulating wall-bounded turbulence by modelling, instead of resolving, the inner region of the turbulent boundary layer up to approximately ![]() $10\,\%$ of the boundary layer thickness (including the viscous, buffer and part of the logarithmic sublayers). Prior work has proven WMLES capable of capturing the flow physics of non-equilibrium, separated STBLIs over adiabatic rigid walls, enabling simulations with long integration times, critical to the analysis of low-frequency unsteadiness, and of interactions with three-dimensional effects (Reference Bermejo-Moreno, Campo, Larsson, Bodart, Helmer and EatonBermejo-Moreno et al., 2014).

$10\,\%$ of the boundary layer thickness (including the viscous, buffer and part of the logarithmic sublayers). Prior work has proven WMLES capable of capturing the flow physics of non-equilibrium, separated STBLIs over adiabatic rigid walls, enabling simulations with long integration times, critical to the analysis of low-frequency unsteadiness, and of interactions with three-dimensional effects (Reference Bermejo-Moreno, Campo, Larsson, Bodart, Helmer and EatonBermejo-Moreno et al., 2014).

The present work focuses on the numerical simulation of a ![]() $M_{\infty } = 3$ strongly separated impinging STBLI over a rectangular flexible panel, replicating the experiments of Reference Daub, Willems and GülhanDaub et al. (2016). The main novelty regarding the numerical methodology resides in the coupling of WMLES (employing an equilibrium-based wall stress model; Reference Kawai and LarssonKawai and Larsson (2012)) and a finite-element solid mechanics solver that incorporates structural damping. The use of WMLES enables the simulation to be performed at the same Reynolds number (

$M_{\infty } = 3$ strongly separated impinging STBLI over a rectangular flexible panel, replicating the experiments of Reference Daub, Willems and GülhanDaub et al. (2016). The main novelty regarding the numerical methodology resides in the coupling of WMLES (employing an equilibrium-based wall stress model; Reference Kawai and LarssonKawai and Larsson (2012)) and a finite-element solid mechanics solver that incorporates structural damping. The use of WMLES enables the simulation to be performed at the same Reynolds number (![]() $Re_{\infty }=49.4\times 10^6\ \mathrm {m}^{-1}$), spanning the full panel width and for the same duration as reported in the experiments, allowing for a more complete characterization of STBLI low-frequency motions and coupling with the flexible panel dynamics. Previous numerical studies of the same experiments were conducted by Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al. (2015) and Reference Zope, Horner, Collins, Bhushan and BhatiaZope, Horner, Collins, Bhushan and Bhatia (2021). The former used wall-resolved LES and a finite-element method hyperelastic Saint–Venant–Kirchoff solid solver that neglected structural damping, with a cut-cell immersed boundary method treatment of the fluid–solid interface. The simulation ran for a shorter duration, remaining in a transient state. Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) utilized both dynamic hybrid RANS/LES and RANS approaches for the flow solver, also neglecting damping in the solid mechanics solver.

$Re_{\infty }=49.4\times 10^6\ \mathrm {m}^{-1}$), spanning the full panel width and for the same duration as reported in the experiments, allowing for a more complete characterization of STBLI low-frequency motions and coupling with the flexible panel dynamics. Previous numerical studies of the same experiments were conducted by Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al. (2015) and Reference Zope, Horner, Collins, Bhushan and BhatiaZope, Horner, Collins, Bhushan and Bhatia (2021). The former used wall-resolved LES and a finite-element method hyperelastic Saint–Venant–Kirchoff solid solver that neglected structural damping, with a cut-cell immersed boundary method treatment of the fluid–solid interface. The simulation ran for a shorter duration, remaining in a transient state. Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) utilized both dynamic hybrid RANS/LES and RANS approaches for the flow solver, also neglecting damping in the solid mechanics solver.

This paper is organized as follows. The problem set-up is introduced in § 2, followed by the description of the computational methodology in § 3. Simulation results for rigid- and flexible-wall cases, considering full-span and spanwise periodic domains, are presented in § 4. When available, simulation results are compared with experimental data and prior numerical studies. Additional quantities not present in experimental studies such as separation bubble statistics, wall pressure spectral density distribution and full-panel deflection are also discussed. The main conclusions of the study are highlighted in § 5.

2. Problem set-up

The simulations performed in this study are modelled after the experiments of Reference Daub, Willems and GülhanDaub et al. (2016). A compression wedge (of ![]() $30^{\circ }$ angle) in a

$30^{\circ }$ angle) in a ![]() $M_{\infty } = 3$ air stream generates an oblique shock that impinges on the turbulent boundary layer developed over a plate with a rectangular elastic insert. Figure 1 shows schematically the experimental set-up and the computational domain of the present simulations, which extends

$M_{\infty } = 3$ air stream generates an oblique shock that impinges on the turbulent boundary layer developed over a plate with a rectangular elastic insert. Figure 1 shows schematically the experimental set-up and the computational domain of the present simulations, which extends ![]() $80$ mm upstream and

$80$ mm upstream and ![]() $40$ mm downstream of the rectangular flexible panel. The leading edge of the rigid wall in the experiments (origin of the absolute

$40$ mm downstream of the rectangular flexible panel. The leading edge of the rigid wall in the experiments (origin of the absolute ![]() $x$ coordinate direction) extends

$x$ coordinate direction) extends ![]() $130$ mm farther upstream from the inlet to the simulations, producing a fully turbulent boundary layer. At the reference station located at

$130$ mm farther upstream from the inlet to the simulations, producing a fully turbulent boundary layer. At the reference station located at ![]() $x=210$ mm, the boundary layer thickness based on 99 % of the free-stream velocity is

$x=210$ mm, the boundary layer thickness based on 99 % of the free-stream velocity is ![]() $\delta _0=4$ mm. The compression wedge spans the full domain width

$\delta _0=4$ mm. The compression wedge spans the full domain width ![]() $Z_d$ and rotates around point

$Z_d$ and rotates around point ![]() $C$ with an angle relative to the horizontal plane,

$C$ with an angle relative to the horizontal plane, ![]() $\theta$, that varies with time before reaching a value of

$\theta$, that varies with time before reaching a value of ![]() $17.5^{\circ }$ in about

$17.5^{\circ }$ in about ![]() $15$ ms, as shown at the top right of figure 1. The incident oblique shock generated at the wedge front (point

$15$ ms, as shown at the top right of figure 1. The incident oblique shock generated at the wedge front (point ![]() $A$) and the front wave of the head of the expansion wave generated at the wedge rear (point

$A$) and the front wave of the head of the expansion wave generated at the wedge rear (point ![]() $E$) intersect the top boundary of the computational domain (

$E$) intersect the top boundary of the computational domain (![]() $y=100\ \text {mm}=25\delta _0$) at points

$y=100\ \text {mm}=25\delta _0$) at points ![]() $P$ and

$P$ and ![]() $Q$, respectively, whose streamwise location and distance vary with time as the wedge rotates, before reaching constant values. The fast initial rotation of the compression wedge drives the initial excitation of panel vibrations. Computationally, this time-dependent boundary condition is implemented using Rankine–Hugoniot and Prandtl–Meyer inviscid-theory relations to determine the flow properties. The (inviscid) impingement point,

$Q$, respectively, whose streamwise location and distance vary with time as the wedge rotates, before reaching constant values. The fast initial rotation of the compression wedge drives the initial excitation of panel vibrations. Computationally, this time-dependent boundary condition is implemented using Rankine–Hugoniot and Prandtl–Meyer inviscid-theory relations to determine the flow properties. The (inviscid) impingement point, ![]() $I$, used as an origin streamwise location (

$I$, used as an origin streamwise location (![]() $x_I=0.328\ \text {m}$) in several figures presented in this study, corresponds to the intersection of the incident oblique shock with the nominally rigid wall calculated from inviscid theory (i.e. without accounting for the boundary layer) and excluding the curvature of the incident shock induced by the interaction with the Prandtl–Meyer expansion generated at the rear corner of the wedge.

$x_I=0.328\ \text {m}$) in several figures presented in this study, corresponds to the intersection of the incident oblique shock with the nominally rigid wall calculated from inviscid theory (i.e. without accounting for the boundary layer) and excluding the curvature of the incident shock induced by the interaction with the Prandtl–Meyer expansion generated at the rear corner of the wedge.

Figure 1. Problem set-up following experiments by Reference Daub, Willems and GülhanDaub et al. (2016) with the simulation domain highlighted in grey on the back vertical plane. Coloured contour maps are obtained from an instantaneous snapshot at ![]() $t=15$ ms from the full-span simulation of the present study, showing the flexible panel vertical displacement,

$t=15$ ms from the full-span simulation of the present study, showing the flexible panel vertical displacement, ![]() $Y_s$, the streamwise component of the wall shear stress vector,

$Y_s$, the streamwise component of the wall shear stress vector, ![]() $\tau _{w,x}$ (in translucent colour), and the streamwise component of the fluid flow velocity,

$\tau _{w,x}$ (in translucent colour), and the streamwise component of the fluid flow velocity, ![]() $u$. The latter is shown on a cropped vertical slice (

$u$. The latter is shown on a cropped vertical slice (![]() $xy$) at the centre of the spanwise domain, highlighting the incident and reflected shocks, the turbulent boundary layer and the separation bubble.

$xy$) at the centre of the spanwise domain, highlighting the incident and reflected shocks, the turbulent boundary layer and the separation bubble.

The elastic panel, made of CK 75 spring steel (see tables 1 and 2), spans ![]() $200$ mm in the transverse direction (

$200$ mm in the transverse direction (![]() $z$), and has a thickness

$z$), and has a thickness ![]() $h=1.47$ mm. In the experiments, the flexible panel was riveted to the upstream and downstream rigid plate sections with two lines of rivets per transverse edge. In the present simulations, the elastic panel is fixed on its transverse ends to the rigid walls. The flexible panel streamwise length is

$h=1.47$ mm. In the experiments, the flexible panel was riveted to the upstream and downstream rigid plate sections with two lines of rivets per transverse edge. In the present simulations, the elastic panel is fixed on its transverse ends to the rigid walls. The flexible panel streamwise length is ![]() $320\ \text {mm}$, corresponding to the distance between the lines of outer rivets used in the experiments. The longitudinal edges of the elastic panel, sealed with soft rubber from an underneath cavity in the experiments, are modelled by free boundary conditions in the simulations. In an attempt to minimize variations of the flow statistics in the spanwise direction, the wind tunnel sidewalls in the experiments were sufficiently far away from the tested panel. The sidewalls are thus not modelled in the present numerical study, which includes simulations that consider two configurations: one with the full span of the panel (

$320\ \text {mm}$, corresponding to the distance between the lines of outer rivets used in the experiments. The longitudinal edges of the elastic panel, sealed with soft rubber from an underneath cavity in the experiments, are modelled by free boundary conditions in the simulations. In an attempt to minimize variations of the flow statistics in the spanwise direction, the wind tunnel sidewalls in the experiments were sufficiently far away from the tested panel. The sidewalls are thus not modelled in the present numerical study, which includes simulations that consider two configurations: one with the full span of the panel (![]() $Z_{d,{full}}=200\ \text {mm} = 50 \delta _0$) and another that assumes spanwise periodicity with a reduced spanwise width (

$Z_{d,{full}}=200\ \text {mm} = 50 \delta _0$) and another that assumes spanwise periodicity with a reduced spanwise width (![]() $Z_{d,{sp}}=20\ \text {mm} = 5 \delta _0$) equal to five times the incoming boundary layer thickness at the reference station (located at

$Z_{d,{sp}}=20\ \text {mm} = 5 \delta _0$) equal to five times the incoming boundary layer thickness at the reference station (located at ![]() $x=200$ mm), denoted as

$x=200$ mm), denoted as ![]() $\delta _0$. Comparison of simulation results in the full-span and spanwise-periodic configurations is used to assess three-dimensional effects stemming from the flexible panel deformation. Additionally, the sensitivity to the thickness of the incoming boundary layer and to the shock strength is evaluated on the spanwise-periodic simulation configuration in § 4.

$\delta _0$. Comparison of simulation results in the full-span and spanwise-periodic configurations is used to assess three-dimensional effects stemming from the flexible panel deformation. Additionally, the sensitivity to the thickness of the incoming boundary layer and to the shock strength is evaluated on the spanwise-periodic simulation configuration in § 4.

Table 1. Free-stream flow variables: Mach number, ![]() $M_{\infty }$; pressure,

$M_{\infty }$; pressure, ![]() $p_{\infty }$; temperature,

$p_{\infty }$; temperature, ![]() $T_{\infty }$; velocity,

$T_{\infty }$; velocity, ![]() $u_{\infty }$. Thickness of the incoming turbulent boundary layer,

$u_{\infty }$. Thickness of the incoming turbulent boundary layer, ![]() $\delta _0$, at the reference location (

$\delta _0$, at the reference location (![]() $x_0=200$ mm). Streamwise location of incident shock impingement over the rigid wall from inviscid theory,

$x_0=200$ mm). Streamwise location of incident shock impingement over the rigid wall from inviscid theory, ![]() $x_I$, for the maximum deflection angle of the compression wedge.

$x_I$, for the maximum deflection angle of the compression wedge.

Table 2. Properties of the flexible panel: Young modulus, ![]() $E_s$; Poisson ratio,

$E_s$; Poisson ratio, ![]() $\nu _s$; density,

$\nu _s$; density, ![]() $\rho _s$; thickness,

$\rho _s$; thickness, ![]() $h$; primary natural frequency,

$h$; primary natural frequency, ![]() $f_n$; mass damping coefficient,

$f_n$; mass damping coefficient, ![]() $a$. Reference time at the first peak of panel deflection,

$a$. Reference time at the first peak of panel deflection, ![]() $t_0$.

$t_0$.

3. Computational methodology

The present simulations are performed with an in-house flow–structure interaction (FSI) solver that uses a loosely coupled partitioned approach whereby the flow and solid domains are discretized with unstructured, body-fitted meshes. At the fluid–solid interface, the two meshes are non-conformal, allowing for a coarse solid mesh and fine flow mesh to exchange information via interpolation. The FSI solver consists of three specialized solvers for the fluid flow, solid mechanics and fluid mesh deformation. For the rigid wall simulations, only the flow solver is used.

The flow solver uses a finite-volume cell-centred formulation of the spatially filtered compressible Navier–Stokes (LES) equations on an unstructured hexahedral-cell mesh. Air is assumed as a calorically perfect gas with a dynamic viscosity modelled by Sutherland's law. For FSI simulations, the motion and deformation of the mesh are accounted for by an arbitrary Lagrangian Eulerian formulation of the conservation equations. Hybrid second-order numerics combine an essentially non-oscillatory scheme near shocks with a centred scheme away from shocks, distinguished by a sensor based on local dilatation, enstrophy and sound speed. To reduce the grid resolution requirements, the flow solver uses the subgrid-scale model of Reference VremanVreman (2004) and the equilibrium wall-stress wall model of Reference Kawai and LarssonKawai and Larsson (2012), with a mixing-length model for the turbulent eddy viscosity.

At each wall face, the simplified equilibrium wall-model ordinary differential equations are solved on a separate one-dimensional grid extending up to a wall-model exchange height ![]() $h_{{wm}}$ from the wall. The wall model applies the instantaneous velocity, pressure and temperature from the LES grid at the exchange height as the top boundary condition, and adiabatic, no-slip boundary condition at the wall. The wall shear stress,

$h_{{wm}}$ from the wall. The wall model applies the instantaneous velocity, pressure and temperature from the LES grid at the exchange height as the top boundary condition, and adiabatic, no-slip boundary condition at the wall. The wall shear stress, ![]() $\tau _w$, calculated by solving the wall-model equations, is applied as the wall boundary condition to the LES grid. At the inlet, synthetic turbulence is generated using a digital filtering technique based on Reference Klein, Sadiki and JanickaKlein, Sadiki, and Janicka (2003), with the extensions proposed by Reference Xie and CastroXie and Castro (2008) and Reference Touber and SandhamTouber and Sandham (2009).

$\tau _w$, calculated by solving the wall-model equations, is applied as the wall boundary condition to the LES grid. At the inlet, synthetic turbulence is generated using a digital filtering technique based on Reference Klein, Sadiki and JanickaKlein, Sadiki, and Janicka (2003), with the extensions proposed by Reference Xie and CastroXie and Castro (2008) and Reference Touber and SandhamTouber and Sandham (2009).

The geometrically nonlinear solid solver uses the finite-element method with ![]() $27$-node hexahedral isoparametric elements, with a linear isotropic material model used to relate stress and strain. The governing equations of motion for the solid solver are

$27$-node hexahedral isoparametric elements, with a linear isotropic material model used to relate stress and strain. The governing equations of motion for the solid solver are ![]() $[M] \ddot {\boldsymbol {u}} + [C] \dot {\boldsymbol {u}} + [K] \boldsymbol {u} + \boldsymbol {f}_{{int}} = \boldsymbol {f}_{{ext}}$, where

$[M] \ddot {\boldsymbol {u}} + [C] \dot {\boldsymbol {u}} + [K] \boldsymbol {u} + \boldsymbol {f}_{{int}} = \boldsymbol {f}_{{ext}}$, where ![]() $\boldsymbol {u}$ is the local displacement vector of the solid mesh nodes relative to the previous deformed state. The mass matrix

$\boldsymbol {u}$ is the local displacement vector of the solid mesh nodes relative to the previous deformed state. The mass matrix ![]() $[M]$ is diagonalized by using the lumped mass approximation, which allows for trivial inversion. To account for geometric nonlinearities, the stiffness matrix

$[M]$ is diagonalized by using the lumped mass approximation, which allows for trivial inversion. To account for geometric nonlinearities, the stiffness matrix ![]() $[K]$, external force vector

$[K]$, external force vector ![]() $\boldsymbol {f}_{{ext}}$ and internal force vector

$\boldsymbol {f}_{{ext}}$ and internal force vector ![]() $\boldsymbol {f}_{{int}}$ are updated at the same frequency as the solid and flow mesh are deformed in the FSI solver. The internal force vector

$\boldsymbol {f}_{{int}}$ are updated at the same frequency as the solid and flow mesh are deformed in the FSI solver. The internal force vector ![]() $\boldsymbol {f}_{{int}}$ is updated by taking the stiffness force

$\boldsymbol {f}_{{int}}$ is updated by taking the stiffness force ![]() $[K] \boldsymbol {u}$ just prior to updating the mesh deformation at each time step and adding it to the existing internal force. This allows for the accounting of geometric nonlinearities such as an increase in panel stiffness with increased deflection. The external force

$[K] \boldsymbol {u}$ just prior to updating the mesh deformation at each time step and adding it to the existing internal force. This allows for the accounting of geometric nonlinearities such as an increase in panel stiffness with increased deflection. The external force ![]() $\boldsymbol {f}_{{ext}}$ is updated using a pressure field interpolated onto the solid mesh from the flow domain. The damping matrix

$\boldsymbol {f}_{{ext}}$ is updated using a pressure field interpolated onto the solid mesh from the flow domain. The damping matrix ![]() $[C]$ is assumed linearly proportional to the mass matrix

$[C]$ is assumed linearly proportional to the mass matrix ![]() $[M]$ by means of the mass damping coefficient,

$[M]$ by means of the mass damping coefficient, ![]() $a$, which is inferred using a weakly dampened oscillator analogy by fitting the experimentally measured time signal of vertical displacement at a probe near the panel centre obtained from Reference Daub, Willems and GülhanDaub et al. (2016) as

$a$, which is inferred using a weakly dampened oscillator analogy by fitting the experimentally measured time signal of vertical displacement at a probe near the panel centre obtained from Reference Daub, Willems and GülhanDaub et al. (2016) as ![]() $Y_s(t)\approx A \, {\rm e}^{-at/2} \cos (2 {\rm \pi}f_n t + \phi ) + B$, obtaining the constants

$Y_s(t)\approx A \, {\rm e}^{-at/2} \cos (2 {\rm \pi}f_n t + \phi ) + B$, obtaining the constants ![]() $a$,

$a$, ![]() $f_n$,

$f_n$, ![]() $A$ and

$A$ and ![]() $B$. Since the damping coefficient is inferred from the panel response of a STBLI FSI experiment, it accounts not only for the structural damping of the panel but also, in part, for the damping introduced by the fluid flow in the wind tunnel and the cavity underneath the panel (e.g. by acoustic radiation). Despite these uncertainties in the determination of the structural damping coefficient, it is shown in § 4 that simulations that incorporate damping significantly improve the accuracy of the predictions. Along the transverse (upstream and downstream) edges of the panel, fixed–fixed (i.e. clamped–clamped) boundary conditions are employed. The static pressure beneath the panel is set to the free-stream pressure, as approximately maintained experimentally in the cavity below the panel. The longitudinal edges (located on

$B$. Since the damping coefficient is inferred from the panel response of a STBLI FSI experiment, it accounts not only for the structural damping of the panel but also, in part, for the damping introduced by the fluid flow in the wind tunnel and the cavity underneath the panel (e.g. by acoustic radiation). Despite these uncertainties in the determination of the structural damping coefficient, it is shown in § 4 that simulations that incorporate damping significantly improve the accuracy of the predictions. Along the transverse (upstream and downstream) edges of the panel, fixed–fixed (i.e. clamped–clamped) boundary conditions are employed. The static pressure beneath the panel is set to the free-stream pressure, as approximately maintained experimentally in the cavity below the panel. The longitudinal edges (located on ![]() $xy$ planes) of the panel remain free to move (i.e. not clamped). In the experiments, a soft rubber foam (not modelled) was used along the edges to seal the cavity. Time integration is performed using the same four-stage explicit Runge–Kutta method used in the flow solver.

$xy$ planes) of the panel remain free to move (i.e. not clamped). In the experiments, a soft rubber foam (not modelled) was used along the edges to seal the cavity. Time integration is performed using the same four-stage explicit Runge–Kutta method used in the flow solver.

The mesh deformation solver uses a face-based spring-system analogy by which each face of the flow mesh is treated as a spring connecting the centroids of the adjacent mesh cells sharing that face. The stiffness of each spring is inversely proportional to the square of the spring (inter-cell) distance. Dirichlet conditions are prescribed along the part of the bottom boundary of the flow mesh corresponding to the interpolated nodal positions of the deformed solid mesh. On the side boundaries (planes normal to the spanwise coordinate direction), the mesh deformation is constrained to the vertical (![]() $y$) direction. The mesh deformation is restricted to a region of influence above the flexible panel up to

$y$) direction. The mesh deformation is restricted to a region of influence above the flexible panel up to ![]() $y\leq 4 \delta _0$ for improved computational performance. The resulting linear system of equations is equivalent to a static finite-element assembly of three-dimensional trusses (Reference RaoRao, 2005).

$y\leq 4 \delta _0$ for improved computational performance. The resulting linear system of equations is equivalent to a static finite-element assembly of three-dimensional trusses (Reference RaoRao, 2005).

The flow domain is discretized using hexahedral-cell, body-fitted meshes that deform with the flexible panel. Near-wall grid spacing follows Reference Larsson, Kawai, Bodart and Bermejo-MorenoLarsson et al. (2016). The first near-wall layer below the wall-model exchange location, chosen as ![]() $10\,\%$ of the reference boundary layer thickness (

$10\,\%$ of the reference boundary layer thickness (![]() $y< h_{{wm}}=0.1\delta _0$), includes four cells with uniform grid spacing (i.e.

$y< h_{{wm}}=0.1\delta _0$), includes four cells with uniform grid spacing (i.e. ![]() $\Delta y=0.25 h_{{wm}}$), intended to reduce numerical errors from the LES transferred to the wall model (Reference Kawai and LarssonKawai & Larsson, 2012) and avoid the log-layer mismatch. Above the exchange location (

$\Delta y=0.25 h_{{wm}}$), intended to reduce numerical errors from the LES transferred to the wall model (Reference Kawai and LarssonKawai & Larsson, 2012) and avoid the log-layer mismatch. Above the exchange location (![]() $h_{{wm}}< y<\delta _0$), the wall-normal spacing increases away from the wall following a hyperbolic tangent law up to

$h_{{wm}}< y<\delta _0$), the wall-normal spacing increases away from the wall following a hyperbolic tangent law up to ![]() $\Delta y = 0.05\delta _0$ at

$\Delta y = 0.05\delta _0$ at ![]() $y=\delta _0$, then remains uniform up to

$y=\delta _0$, then remains uniform up to ![]() $y=4\delta _0$, and stretches again up to the top boundary (

$y=4\delta _0$, and stretches again up to the top boundary (![]() $4\delta _0< y<25\delta _0$) with another hyperbolic tangent law. Uniform mesh spacing is used in the streamwise and spanwise directions, with

$4\delta _0< y<25\delta _0$) with another hyperbolic tangent law. Uniform mesh spacing is used in the streamwise and spanwise directions, with ![]() $\Delta x \approx 0.08 \delta _0$ and

$\Delta x \approx 0.08 \delta _0$ and ![]() $\Delta z = 0.05 \delta _0$, respectively. Grid convergence was assessed in our prior simulation study and is not repeated here (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021). The resulting number of cells in the flow solver mesh corresponds to approximately

$\Delta z = 0.05 \delta _0$, respectively. Grid convergence was assessed in our prior simulation study and is not repeated here (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021). The resulting number of cells in the flow solver mesh corresponds to approximately ![]() $20$ and

$20$ and ![]() $200$ million for the spanwise-periodic and full-span domains, respectively. The solid domain is discretized with

$200$ million for the spanwise-periodic and full-span domains, respectively. The solid domain is discretized with ![]() $64$ cells (27-node isoparametric elements) in the streamwise direction, one cell across the panel thickness and

$64$ cells (27-node isoparametric elements) in the streamwise direction, one cell across the panel thickness and ![]() $2$ (spanwise-periodic) or

$2$ (spanwise-periodic) or ![]() $20$ (full-span) cells in the spanwise direction. This results in a modest number of

$20$ (full-span) cells in the spanwise direction. This results in a modest number of ![]() $128$ and

$128$ and ![]() $1280$ finite elements for the reduced and full-span simulations, respectively. Time integration employs a four-stage explicit Runge–Kutta method with a constant time step

$1280$ finite elements for the reduced and full-span simulations, respectively. Time integration employs a four-stage explicit Runge–Kutta method with a constant time step ![]() $\Delta t=10^{-7}\ \text {s}$, which is below the Courant–Friedrichs–Lewy condition for the flow solver, and within the stability limits of the solid solver.

$\Delta t=10^{-7}\ \text {s}$, which is below the Courant–Friedrichs–Lewy condition for the flow solver, and within the stability limits of the solid solver.

At the fluid–solid interface, the flow and solid meshes are non-conforming. The flow mesh faces are much smaller than the solid mesh faces, due to the finer grid resolution required to capture the near-wall flow physics, compared with the structural deformation. The flow wall pressure field is spatially mean-filtered onto the coarser solid mesh. The resulting pressure imposed on each solid face is the area-weighted sum of the wall pressure acting on flow faces in contact with that solid face. The wall displacement field is interpolated onto the flow mesh using the finite-element shape functions of the solid solver: each point of the flow mesh in contact with the solid domain is matched to a quadrilateral solid face, its finite element natural coordinates are substituted back into the shape functions of that solid face.

4. Results

We first assess the three-dimensionality of the interaction by conducting a FSI simulation that includes the full span of the experimental panel (![]() $Z_d=200\ \text {mm}=50\delta _0$), comparing results with a prior spanwise-periodic simulation over a reduced span (

$Z_d=200\ \text {mm}=50\delta _0$), comparing results with a prior spanwise-periodic simulation over a reduced span (![]() $Z_d=20 \text {mm}=5\delta _0$) (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021) and available experimental measurements (Reference Daub, Willems and GülhanDaub et al., 2016). The sensitivity of the STBLI strength to variations of the incoming boundary layer thickness and the compression wedge extent is then evaluated for spanwise-periodic simulations with the reduced span over a rigid wall. Finally, we analyse the impact of panel flexibility on the flow physics, comparing simulation results between rigid and flexible wall cases with a stronger interaction than previously reported (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021). When appropriate, we non-dimensionalize the time, streamwise, wall-normal and spanwise coordinates as

$Z_d=20 \text {mm}=5\delta _0$) (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021) and available experimental measurements (Reference Daub, Willems and GülhanDaub et al., 2016). The sensitivity of the STBLI strength to variations of the incoming boundary layer thickness and the compression wedge extent is then evaluated for spanwise-periodic simulations with the reduced span over a rigid wall. Finally, we analyse the impact of panel flexibility on the flow physics, comparing simulation results between rigid and flexible wall cases with a stronger interaction than previously reported (Reference Hoy and Bermejo-MorenoHoy & Bermejo-Moreno, 2021). When appropriate, we non-dimensionalize the time, streamwise, wall-normal and spanwise coordinates as ![]() $t' = f_n (t - t_0)$,

$t' = f_n (t - t_0)$, ![]() $x' = (x - x_I) / \delta _0$,

$x' = (x - x_I) / \delta _0$, ![]() $y' = y / \delta _0$ and

$y' = y / \delta _0$ and ![]() $z' = (z - Z_d/2) / \delta _0$, respectively, where

$z' = (z - Z_d/2) / \delta _0$, respectively, where ![]() $f_n$ is the panel first natural frequency,

$f_n$ is the panel first natural frequency, ![]() $t=0$ is the start time of the compression wedge rotation,

$t=0$ is the start time of the compression wedge rotation, ![]() $t_0$ is the reference time at the first peak of panel deflection,

$t_0$ is the reference time at the first peak of panel deflection, ![]() $x_I$ is the inviscid shock impingement location for the maximum deflection angle of the compression wedge (

$x_I$ is the inviscid shock impingement location for the maximum deflection angle of the compression wedge (![]() $\theta _{{max}}=17.5^{\circ }$),

$\theta _{{max}}=17.5^{\circ }$), ![]() $Z_d$ is the spanwise domain width and

$Z_d$ is the spanwise domain width and ![]() $\delta _0$ is the reference boundary layer thickness (see tables 1 and 2).

$\delta _0$ is the reference boundary layer thickness (see tables 1 and 2).

Based on the observed temporal evolution of the panel spatially averaged kinetic energy and the flow separation bubble dynamics (see figure 2), we identify three phases of the present FSI termed transient, transition and long-term phases. The transient phase corresponds to the rotation of the wedge from zero deflection until reaching the set point of ![]() $17.5^{\circ }$. This transient phase is characterized by the largest panel deflection (reached halfway during the wedge rotation and followed by a slower decay) and the formation of the shock system and the flow separation bubble, whose volume rapidly increases after an initial lag of approximately

$17.5^{\circ }$. This transient phase is characterized by the largest panel deflection (reached halfway during the wedge rotation and followed by a slower decay) and the formation of the shock system and the flow separation bubble, whose volume rapidly increases after an initial lag of approximately ![]() $1$ ms, reaching a statistically stationary value by the end of the transient phase. In the transition phase, the kinetic energy of the flexible panel slowly decreases over approximately eight cycles of primary natural vibration before reaching a statistically stationary value that defines the long-term phase. For the strongly separated STBLI considered in this study and its associated low-frequency flow motions, the flexible panel never reaches a fully static state. Instead, in the long-term phase, the panel reaches a limit-cycle oscillation state where the rate of energy lost from damping is balanced by the rate of energy added from the pressure fluctuations and low-frequency motions from the STBLI. The magnitude of these vibrations scales roughly with the inverse of the damping ratio

$1$ ms, reaching a statistically stationary value by the end of the transient phase. In the transition phase, the kinetic energy of the flexible panel slowly decreases over approximately eight cycles of primary natural vibration before reaching a statistically stationary value that defines the long-term phase. For the strongly separated STBLI considered in this study and its associated low-frequency flow motions, the flexible panel never reaches a fully static state. Instead, in the long-term phase, the panel reaches a limit-cycle oscillation state where the rate of energy lost from damping is balanced by the rate of energy added from the pressure fluctuations and low-frequency motions from the STBLI. The magnitude of these vibrations scales roughly with the inverse of the damping ratio ![]() $\zeta$. These panel oscillations remain coupled with the STBLI flow dynamics.

$\zeta$. These panel oscillations remain coupled with the STBLI flow dynamics.

Figure 2. Temporal evolution of dimensionless specific panel kinetic energy ![]() $\overline {u_s^2} / (f_n \delta _0)^2$ (shown in blue with a logarithmic scale on the left-hand vertical axis), separation bubble volume

$\overline {u_s^2} / (f_n \delta _0)^2$ (shown in blue with a logarithmic scale on the left-hand vertical axis), separation bubble volume ![]() $V_b / (Z_d \delta _0^2)$ (shown in red with a linear scale on the right-hand vertical axis) and wedge angle

$V_b / (Z_d \delta _0^2)$ (shown in red with a linear scale on the right-hand vertical axis) and wedge angle ![]() $\theta$ (shown in green with a linear scale on the right-hand vertical axis).

$\theta$ (shown in green with a linear scale on the right-hand vertical axis).

4.1 Three-dimensionality of panel displacement, skin friction and wall pressure

Figure 3(a) shows contours of the vertical deflection of the flexible panel along the midspan plane (![]() $z=0$ mm) as a function of time and streamwise direction, obtained from the full-span FSI simulation. Nonlinearity and asymmetry dominate the panel deflection, characterized by an initial transient period (

$z=0$ mm) as a function of time and streamwise direction, obtained from the full-span FSI simulation. Nonlinearity and asymmetry dominate the panel deflection, characterized by an initial transient period (![]() $t'<3$). Starting from an equilibrium condition with zero panel deflection at

$t'<3$). Starting from an equilibrium condition with zero panel deflection at ![]() $t=0$, when the pressure on both sides of the panel is the same, the increased pressure force produced by the impinging oblique shock generated by the rotating compression wedge deflects the flexible panel. After the first peak of panel deflection is reached at

$t=0$, when the pressure on both sides of the panel is the same, the increased pressure force produced by the impinging oblique shock generated by the rotating compression wedge deflects the flexible panel. After the first peak of panel deflection is reached at ![]() $t=t_0$, damped oscillations occur about a mean deflection state. A quantitative comparison of the panel deflection as a function of time is presented in figure 3(b) for three probe locations where experimental measurements were reported by Reference Daub, Willems and GülhanDaub et al. (2016). These probes were placed along the panel centreline (

$t=t_0$, damped oscillations occur about a mean deflection state. A quantitative comparison of the panel deflection as a function of time is presented in figure 3(b) for three probe locations where experimental measurements were reported by Reference Daub, Willems and GülhanDaub et al. (2016). These probes were placed along the panel centreline (![]() $z = Z_d/2$) at streamwise locations

$z = Z_d/2$) at streamwise locations ![]() $x = 295$,

$x = 295$, ![]() $375$ and

$375$ and ![]() $445$ mm, denoted front, centre and rear, respectively. The vertical dashed lines in figure 3(a) correspond to the three probe locations. The time signals of panel deflection at the three probes shown in figure 3(b) compare results from the full-span simulation, spanwise-periodic simulation with a reduced span and experiments.

$445$ mm, denoted front, centre and rear, respectively. The vertical dashed lines in figure 3(a) correspond to the three probe locations. The time signals of panel deflection at the three probes shown in figure 3(b) compare results from the full-span simulation, spanwise-periodic simulation with a reduced span and experiments.

Figure 3. (a) Contours of vertical panel displacement, ![]() $Y_s / \delta _0$, along the midspan plane as a function the streamwise coordinate and time, obtained from the full-span simulation. Grey colours indicate positive vertical deflection. (b) Time signals of panel displacement measured at the front (red), centre (blue) and rear (green) probe locations marked by vertical dashed lines in (a), comparing results from full-span simulations (solid), previous spanwise-periodic reduced-span simulations (dashed) by Reference Hoy and Bermejo-MorenoHoy and Bermejo-Moreno (2021) and experiments (dotted) by Reference Daub, Willems and GülhanDaub et al. (2016).

$Y_s / \delta _0$, along the midspan plane as a function the streamwise coordinate and time, obtained from the full-span simulation. Grey colours indicate positive vertical deflection. (b) Time signals of panel displacement measured at the front (red), centre (blue) and rear (green) probe locations marked by vertical dashed lines in (a), comparing results from full-span simulations (solid), previous spanwise-periodic reduced-span simulations (dashed) by Reference Hoy and Bermejo-MorenoHoy and Bermejo-Moreno (2021) and experiments (dotted) by Reference Daub, Willems and GülhanDaub et al. (2016).

Full-span simulations predict the experimental deflection measurements with reasonable accuracy, especially for the centre probe. The largest differences are observed for the front and rear probes near the first two peaks of deflection, which are over- and under-predicted, respectively. After the transient, signals for the three probes recover dampened oscillations around a mean deflection curve in close agreement with experiments, including the amplitudes and frequencies of oscillation. Contributing factors to the observed differences from experiments include: (1) the large sensitivity of panel displacement to the exact probe streamwise location, observed in figure 3(a); (2) the modelling of the transverse rows of rivets used in the experiments with a simplified fixed–fixed boundary condition in the simulations; and (3) neglecting, in the simulations, the foam sealing on the streamwise edges of the flexible panel used experimentally to prevent leakage into the underneath cavity, which may increase the stiffness along the edges (Reference Willems, Gulhan and EsserWillems et al., 2013). The use of a mass proportional damping model provides a reasonable approximation of primary modal damping of the panel (compare, for example, with prior FSI simulations without damping by Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al. (2015)), but with limitations. Damping effects caused by the foam sealing along the sides are not modelled. Also, with mass proportional damping, higher-frequency vibrations have smaller damping ratios than the primary frequency, so high-frequency content takes longer to damp out.

We assess in figure 4 the three-dimensionality of the flow through contour plots of the panel deflection, skin friction coefficient and wall pressure, mapped on the flexible panel and projected onto the horizontal (![]() $xz$) plane, time-averaged after the initial transient. Three-dimensional effects are most noticeable in the panel deflection (figure 4a) near the longitudinal edges (

$xz$) plane, time-averaged after the initial transient. Three-dimensional effects are most noticeable in the panel deflection (figure 4a) near the longitudinal edges (![]() $|z'|>15$), where the deflection exceeds that of the panel centreline, especially for streamwise locations of maximum wall pressure (

$|z'|>15$), where the deflection exceeds that of the panel centreline, especially for streamwise locations of maximum wall pressure (![]() $0\lesssim x' \lesssim 20$). The foam sealing (not modelled in the present simulations) used in the experiments along the longitudinal edges (Reference Daub, Willems and GülhanDaub et al., 2016) may add a slight stiffness along the edges, reducing the deflection difference between the centreline and the edges of the panel. Consistent with our fixed–fixed (along transverse edges) panel model, detailed static finite-element simulations performed by Reference Willems, Gulhan and EsserWillems et al. (2013), which accounted for panel riveting, also found the panel deflection to be larger along the edges of the panel. Contours of the time-averaged skin friction coefficient (figure 4b) show a predominantly two-dimensional character, except very near the longitudinal edges (

$0\lesssim x' \lesssim 20$). The foam sealing (not modelled in the present simulations) used in the experiments along the longitudinal edges (Reference Daub, Willems and GülhanDaub et al., 2016) may add a slight stiffness along the edges, reducing the deflection difference between the centreline and the edges of the panel. Consistent with our fixed–fixed (along transverse edges) panel model, detailed static finite-element simulations performed by Reference Willems, Gulhan and EsserWillems et al. (2013), which accounted for panel riveting, also found the panel deflection to be larger along the edges of the panel. Contours of the time-averaged skin friction coefficient (figure 4b) show a predominantly two-dimensional character, except very near the longitudinal edges (![]() $|z'|>20$) downstream of the inviscid impingement location (

$|z'|>20$) downstream of the inviscid impingement location (![]() $x'>0$), which may be attributed to the symmetry (slip-wall) boundary conditions imposed by the flow solver on the side boundaries of the computational domain for this full-span simulation. Downstream of the boundary layer reattachment (

$x'>0$), which may be attributed to the symmetry (slip-wall) boundary conditions imposed by the flow solver on the side boundaries of the computational domain for this full-span simulation. Downstream of the boundary layer reattachment (![]() $15\lesssim x' \lesssim 40$), the time-averaged skin friction exhibits streamwise streaks leading to ragged spanwise contours. These are attributed to larger-scale turbulent flow structures produced by the shear layer resulting from the STBLI (see figures 1 and 6b) and Görtler-like vortices, previously found in wall-resolved LES by Reference Pasquariello, Hickel and AdamsPasquariello, Hickel, and Adams (2017) of the rigid-wall STBLI, with a spanwise wavelength of approximately

$15\lesssim x' \lesssim 40$), the time-averaged skin friction exhibits streamwise streaks leading to ragged spanwise contours. These are attributed to larger-scale turbulent flow structures produced by the shear layer resulting from the STBLI (see figures 1 and 6b) and Görtler-like vortices, previously found in wall-resolved LES by Reference Pasquariello, Hickel and AdamsPasquariello, Hickel, and Adams (2017) of the rigid-wall STBLI, with a spanwise wavelength of approximately ![]() $2\delta _0$, requiring much longer averaging time periods to homogenize. Lastly, the time-averaged wall pressure contours shown in figure 4(c) exhibit minimal three-dimensionality. In conclusion, the presently studied interaction can be approximated as statistically two-dimensional, enabling the use of spanwise-periodic simulations, which is the focus of the remaining analysis.

$2\delta _0$, requiring much longer averaging time periods to homogenize. Lastly, the time-averaged wall pressure contours shown in figure 4(c) exhibit minimal three-dimensionality. In conclusion, the presently studied interaction can be approximated as statistically two-dimensional, enabling the use of spanwise-periodic simulations, which is the focus of the remaining analysis.

Figure 4. (a) Normalized panel displacement, ![]() $Y_s/\delta _0$, (b) skin friction coefficient,

$Y_s/\delta _0$, (b) skin friction coefficient, ![]() $C_f \times 10^3$, and (c) normalized wall pressure,

$C_f \times 10^3$, and (c) normalized wall pressure, ![]() $p_w/p_{\infty }$, time-averaged (

$p_w/p_{\infty }$, time-averaged (![]() $t \in [20,60]$ ms) on the streamwise–spanwise (

$t \in [20,60]$ ms) on the streamwise–spanwise (![]() $xz$) plane, for the full-span FSI simulation.

$xz$) plane, for the full-span FSI simulation.

4.2 Sensitivity of the STBLI to wedge length and incoming boundary layer thickness

Two main sources of uncertainty when comparing the present simulations with experiments stem from viscous effects of the flow around the compression wedge and the development of the incoming boundary layer. The compression wedge that generates the oblique shock impinging on the panel is not included in the computational domain, but its effect is modelled through the top boundary of the flow computational domain, where time-varying Rankine–Hugoniot and Prandtl–Meyer inviscid flow conditions are prescribed, following Reference Pasquariello, Hickel and AdamsPasquariello et al. (2017). While effective at reducing the computational cost, such top boundary condition neglects the wedge boundary layers and wake, which can alter the Prandtl–Meyer expansion generated at the rear corner of the wedge and its interaction with the oblique shock, thus affecting the strength of the STBLI on the panel (see figure 1). A second source of uncertainty arises from an incomplete characterization of the incoming boundary layer in the experiments, which relied on Pitot-rake and global turbulent intensity (longitudinal and transverse) measurements at one location (![]() $x=150$ mm) upstream of the STBLI. The strength of the interaction and, in turn, the extent of flow separation depend on the incoming boundary layer thickness (Reference Zhou, Zhao and ZhaoZhou, Zhao, & Zhao, 2019).

$x=150$ mm) upstream of the STBLI. The strength of the interaction and, in turn, the extent of flow separation depend on the incoming boundary layer thickness (Reference Zhou, Zhao and ZhaoZhou, Zhao, & Zhao, 2019).

We assess in figure 5 the effects of these uncertainties on the wall-pressure profiles characterizing the STBLI from two parametric studies conducted on spanwise-periodic rigid-wall simulations by: (1) extending the wedge length by a factor ![]() $\xi$ (in

$\xi$ (in ![]() $2~\text {mm}$ increments), for the same wedge angle of

$2~\text {mm}$ increments), for the same wedge angle of ![]() $30^{\circ }$, which delays the interaction of the expansion fan and the shock; and (2) modifying the incoming boundary layer thickness by a factor

$30^{\circ }$, which delays the interaction of the expansion fan and the shock; and (2) modifying the incoming boundary layer thickness by a factor ![]() $\eta$ relative to the reference value inferred experimentally of

$\eta$ relative to the reference value inferred experimentally of ![]() $\delta _0=4$ mm. A subset of the simulation results is presented in figure 5, for clarity. As seen in figure 5(a), wedge length extensions strengthen the STBLI, which is initiated farther upstream and reaches a larger pressure peak for increasing

$\delta _0=4$ mm. A subset of the simulation results is presented in figure 5, for clarity. As seen in figure 5(a), wedge length extensions strengthen the STBLI, which is initiated farther upstream and reaches a larger pressure peak for increasing ![]() $\xi$, while preserving a similar pressure profile shape. In contrast, a thicker incoming boundary layer alters the shape of the pressure profile by also bringing the initial pressure rise (corresponding to the separation shock) farther upstream while decreasing the maximum wall pressure reached throughout the STBLI (figure 5b). Comparison with experimental wall-pressure profiles provided the best agreement for a

$\xi$, while preserving a similar pressure profile shape. In contrast, a thicker incoming boundary layer alters the shape of the pressure profile by also bringing the initial pressure rise (corresponding to the separation shock) farther upstream while decreasing the maximum wall pressure reached throughout the STBLI (figure 5b). Comparison with experimental wall-pressure profiles provided the best agreement for a ![]() $6$ mm wedge extension (

$6$ mm wedge extension (![]() $\xi =1.069$) and an incoming boundary layer

$\xi =1.069$) and an incoming boundary layer ![]() $20\,\%$ thicker than the

$20\,\%$ thicker than the ![]() $4$ mm reference value (

$4$ mm reference value (![]() $\eta =1.2$). These values are used in the spanwise-periodic, rigid- and flexible-wall simulations presented in the remaining sections to evaluate the effect of panel flexibility on the STBLI.

$\eta =1.2$). These values are used in the spanwise-periodic, rigid- and flexible-wall simulations presented in the remaining sections to evaluate the effect of panel flexibility on the STBLI.

Figure 5. Sensitivity of streamwise profiles of time- and spanwise-averaged wall pressure over a rigid panel to variations in (a) wedge length (![]() $\xi$) for an incoming boundary layer thickness with

$\xi$) for an incoming boundary layer thickness with ![]() $\eta =1.2$ and (b) incoming boundary layer thickness (

$\eta =1.2$ and (b) incoming boundary layer thickness (![]() $\eta$) for a wedge extension with

$\eta$) for a wedge extension with ![]() $\xi =1.069$. Symbols represent experimental measurements by Reference Daub, Willems and GülhanDaub et al. (2016).

$\xi =1.069$. Symbols represent experimental measurements by Reference Daub, Willems and GülhanDaub et al. (2016).

4.3 Effects of panel flexibility on wall pressure, skin friction and separation bubble characteristics

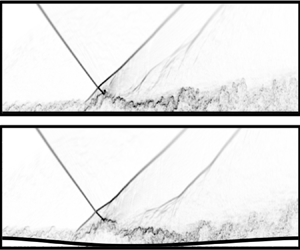

A qualitative comparison of rigid and flexible mean streamwise velocity contours and instantaneous density gradient magnitude along the midspan plane (![]() $z = Z_d/2$) and above the panel insert (

$z = Z_d/2$) and above the panel insert (![]() $210\ \text {mm} \leq x \leq 530$ mm) is shown in figure 6 (time-series animations comprising the total integration time of the simulations are provided as supplementary movies available at https://doi.org/10.1017/flo.2022.28). The turbulent boundary layer separates and reattaches due to the interaction with the shock system, significantly thickening downstream.

$210\ \text {mm} \leq x \leq 530$ mm) is shown in figure 6 (time-series animations comprising the total integration time of the simulations are provided as supplementary movies available at https://doi.org/10.1017/flo.2022.28). The turbulent boundary layer separates and reattaches due to the interaction with the shock system, significantly thickening downstream.

Figure 6. Flexible (bottom) and rigid (top) panel comparison of (a) mean streamwise velocity ![]() $\bar {u}$ and (b) numerical schlieren

$\bar {u}$ and (b) numerical schlieren ![]() $|\nabla \rho |$, above the panel (

$|\nabla \rho |$, above the panel (![]() $210 \leq x \leq 530$ mm), along the midspan plane (

$210 \leq x \leq 530$ mm), along the midspan plane (![]() $z=0$ mm), time-averaged (

$z=0$ mm), time-averaged (![]() $t \in [20,60]$ ms) for rigid- and flexible-wall simulations, zooming into the STBLI region. White contour lines on the mean velocity plots mark the time-averaged region of flow reversal. An animation for the full integration time of the simulation is provided as supplementary movies.

$t \in [20,60]$ ms) for rigid- and flexible-wall simulations, zooming into the STBLI region. White contour lines on the mean velocity plots mark the time-averaged region of flow reversal. An animation for the full integration time of the simulation is provided as supplementary movies.

The temporal evolution of wall pressure is significantly affected by panel flexibility, as shown in figure 7. Compared with the rigid-wall case, for which the pressure remains uniform upstream of the separation shock, the deformation of the flexible panel induces a clear drop of wall pressure upstream of the shock impingement, consistent with the supersonic flow over the diverging geometry that results from the panel deflection. This upstream drop in pressure over the panel prior to flow separation is accurately estimated by local piston theory as described in Reference Sullivan and BodonySullivan and Bodony (2019). The wall pressure is modulated by the panel vibrational frequencies, which vary throughout the panel streamwise extent and can be mapped to the panel displacement frequencies seen in figure 9(a) (compare the regions near the start and end of the panel, for example, with higher and lower vibrational frequencies, respectively, and the corresponding wall-pressure modulation). The pressure rise corresponding to the separation shock is brought farther upstream in the flexible case.

Figure 7. Contours of spanwise-averaged wall pressure ![]() $p_w / p_{\infty }$ as a function of streamwise coordinate and time for rigid (a) and flexible (b) panel simulations. Vertical dashed lines mark the extent of the flexible panel.

$p_w / p_{\infty }$ as a function of streamwise coordinate and time for rigid (a) and flexible (b) panel simulations. Vertical dashed lines mark the extent of the flexible panel.

We present in figure 8(a,b) streamwise profiles of the wall pressure, ![]() $p_w$, and the friction coefficient,

$p_w$, and the friction coefficient, ![]() $C_f$, averaged in the spanwise

$C_f$, averaged in the spanwise ![]() $z$ direction and in time for

$z$ direction and in time for ![]() $t \in [20,60]$ ms. Compared with the rigid-wall case, the wall pressure decreases over the flexible panel upstream of the shock impingement, as observed in figure 7. The pressure drop is accompanied by a decrease in the skin friction coefficient, leading to the boundary layer separating about

$t \in [20,60]$ ms. Compared with the rigid-wall case, the wall pressure decreases over the flexible panel upstream of the shock impingement, as observed in figure 7. The pressure drop is accompanied by a decrease in the skin friction coefficient, leading to the boundary layer separating about ![]() $3\delta _0$ farther upstream in the flexible panel case (

$3\delta _0$ farther upstream in the flexible panel case (![]() $x'\approx -9.4$) than in the rigid case (

$x'\approx -9.4$) than in the rigid case (![]() $x'\approx -6.4$). The peak wall pressure of the rigid STBLI is greater than for the flexible case. The pressure drop over the panel prior to flow separation and the reduction of peak wall pressure compared with the rigid case are also seen in numerical simulations by Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) and Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al. (2015), and experiments by Reference Gramola, Bruce and SanterGramola et al. (2020) and Reference Varigonda and NarayanaswamyVarigonda and Narayanaswamy (2019). For the flexible panel, the wall pressure peaks farther downstream and rises (induced by the separation shock) farther upstream than in the rigid-wall configuration. To better understand fluctuations that are not directly stemming from high frequencies in the turbulent boundary layer, a low-pass filter (with a cut-off frequency

$x'\approx -6.4$). The peak wall pressure of the rigid STBLI is greater than for the flexible case. The pressure drop over the panel prior to flow separation and the reduction of peak wall pressure compared with the rigid case are also seen in numerical simulations by Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) and Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al. (2015), and experiments by Reference Gramola, Bruce and SanterGramola et al. (2020) and Reference Varigonda and NarayanaswamyVarigonda and Narayanaswamy (2019). For the flexible panel, the wall pressure peaks farther downstream and rises (induced by the separation shock) farther upstream than in the rigid-wall configuration. To better understand fluctuations that are not directly stemming from high frequencies in the turbulent boundary layer, a low-pass filter (with a cut-off frequency ![]() $f = u_\infty / L_{{sep}}$) is applied to each of the time signals of wall pressure and skin friction followed by a calculation of standard deviation at each probe location (as shown in figure 8c,d). This follows the approach taken by Reference Pasquariello, Hickel and AdamsPasquariello et al. (2017) with an identical incoming turbulent flow over a rigid wall and a larger wedge deflection angle

$f = u_\infty / L_{{sep}}$) is applied to each of the time signals of wall pressure and skin friction followed by a calculation of standard deviation at each probe location (as shown in figure 8c,d). This follows the approach taken by Reference Pasquariello, Hickel and AdamsPasquariello et al. (2017) with an identical incoming turbulent flow over a rigid wall and a larger wedge deflection angle ![]() $\theta _{{max}} = 19.6^{\circ }$. Similar to that case, the first peak of wall-pressure fluctuations corresponds to pitching low-frequency motions from flow separation. The second peak occurs from reattachment of the shear layer. The first peak of fluctuations shows the flexible panel experiencing flow separation farther upstream and with a lower overall magnitude of fluctuation in relation to the rigid panel (when low-pass-filtered). The second peak is lower and occurs farther downstream for the flexible panel, indicating a longer distance until the flow reattaches itself.

$\theta _{{max}} = 19.6^{\circ }$. Similar to that case, the first peak of wall-pressure fluctuations corresponds to pitching low-frequency motions from flow separation. The second peak occurs from reattachment of the shear layer. The first peak of fluctuations shows the flexible panel experiencing flow separation farther upstream and with a lower overall magnitude of fluctuation in relation to the rigid panel (when low-pass-filtered). The second peak is lower and occurs farther downstream for the flexible panel, indicating a longer distance until the flow reattaches itself.

Figure 8. Time- and spanwise-averaged streamwise profiles of (a) wall pressure ![]() $p_w$ and (b) skin friction coefficient

$p_w$ and (b) skin friction coefficient ![]() $C_f$. Zoomed-in flexible- and rigid-panel comparison of band-limited (

$C_f$. Zoomed-in flexible- and rigid-panel comparison of band-limited (![]() $St_{{sep}} = f L_{{sep}} / u_\infty < 1$) root mean square of (c) wall-pressure

$St_{{sep}} = f L_{{sep}} / u_\infty < 1$) root mean square of (c) wall-pressure ![]() $p_w^\prime$ fluctuations and (d) streamwise skin friction

$p_w^\prime$ fluctuations and (d) streamwise skin friction ![]() $C_f^\prime$ fluctuations. Solid red line, rigid-panel WMLES; solid blue line, flexible-panel WMLES FSI; dashed red line with symbols, rigid experimental data (Reference Daub, Willems and GülhanDaub et al., 2016); dashed blue line, wall-resolved LES averaged over one oscillation period in the transient phase (Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al., 2015). Black vertical dashed lines in (a,b) mark the extent of the flexible panel.

$C_f^\prime$ fluctuations. Solid red line, rigid-panel WMLES; solid blue line, flexible-panel WMLES FSI; dashed red line with symbols, rigid experimental data (Reference Daub, Willems and GülhanDaub et al., 2016); dashed blue line, wall-resolved LES averaged over one oscillation period in the transient phase (Reference Pasquariello, Hickel, Adams, Hammerl, Wall, Daub and GülhanPasquariello et al., 2015). Black vertical dashed lines in (a,b) mark the extent of the flexible panel.

Panel flexibility also leads to a significant (![]() $60\,\%$) increase of the separation length (from

$60\,\%$) increase of the separation length (from ![]() $L_{{sep}}/\delta _0\approx 7.8$ to

$L_{{sep}}/\delta _0\approx 7.8$ to ![]() $12.6$ in the rigid and flexible cases, respectively), which translates into a larger plateau of the wall-pressure streamwise profile. Using lower-fidelity simulations, Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) also found an increase in separation length with panel flexibility. Recent experiments by Reference Neet and AustinNeet and Austin (2020) on the effect of panel compliance on STBLI at

$12.6$ in the rigid and flexible cases, respectively), which translates into a larger plateau of the wall-pressure streamwise profile. Using lower-fidelity simulations, Reference Zope, Horner, Collins, Bhushan and BhatiaZope et al. (2021) also found an increase in separation length with panel flexibility. Recent experiments by Reference Neet and AustinNeet and Austin (2020) on the effect of panel compliance on STBLI at ![]() $M_{\infty } = 4$ also observed an increase in the separation length for comparable non-dimensional panel deflections.

$M_{\infty } = 4$ also observed an increase in the separation length for comparable non-dimensional panel deflections.

Contours of power spectral density (PSD) of wall pressure for the rigid and flexible cases are superimposed in figure 9, along with the PSD of the flexible panel deflection, obtained after the transient (![]() $t'>3$). For the flexible panel case, the streamwise location of low-frequency motions is shifted upstream by approximately

$t'>3$). For the flexible panel case, the streamwise location of low-frequency motions is shifted upstream by approximately ![]() $3\delta _0$ and its extent is widened, indicating a larger amplitude of upstream–downstream motions of the separation shock. The intermediate frequencies, characteristic of the separation bubble region and flapping motions of the shear layer produced by the STBLI, are downshifted for the flexible panel case, extending farther downstream, consistent with the larger separation bubble length. The fundamental frequency of the panel is

$3\delta _0$ and its extent is widened, indicating a larger amplitude of upstream–downstream motions of the separation shock. The intermediate frequencies, characteristic of the separation bubble region and flapping motions of the shear layer produced by the STBLI, are downshifted for the flexible panel case, extending farther downstream, consistent with the larger separation bubble length. The fundamental frequency of the panel is ![]() $f_n \approx 230\ \text {Hz}$, corresponding to a Strouhal number based on the incoming boundary layer thickness and the free-stream velocity of

$f_n \approx 230\ \text {Hz}$, corresponding to a Strouhal number based on the incoming boundary layer thickness and the free-stream velocity of ![]() $St_n = f_n \delta _0 / U_{\infty } = 0.0017$. The PSD of flexible-panel deflection partially overlaps with the low-frequency motions of the flow. A higher vibrational frequency range is observed for the upstream region of the panel (

$St_n = f_n \delta _0 / U_{\infty } = 0.0017$. The PSD of flexible-panel deflection partially overlaps with the low-frequency motions of the flow. A higher vibrational frequency range is observed for the upstream region of the panel (![]() $x'<10$), where low-frequency flow motions dominate. Farther downstream, in the rear part of the flexible panel (

$x'<10$), where low-frequency flow motions dominate. Farther downstream, in the rear part of the flexible panel (![]() $x'>10$), a downshift of the primary natural frequency

$x'>10$), a downshift of the primary natural frequency ![]() $f_n$ is observed.

$f_n$ is observed.